Zinc oxide blanking device

A zinc oxide and discharge device technology, applied in the direction of zinc oxide/zinc hydroxide, transportation and packaging, loading/unloading, etc., can solve the problems of reduced output, reduced zinc oxide processing efficiency, material blockage, etc., and achieves a compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

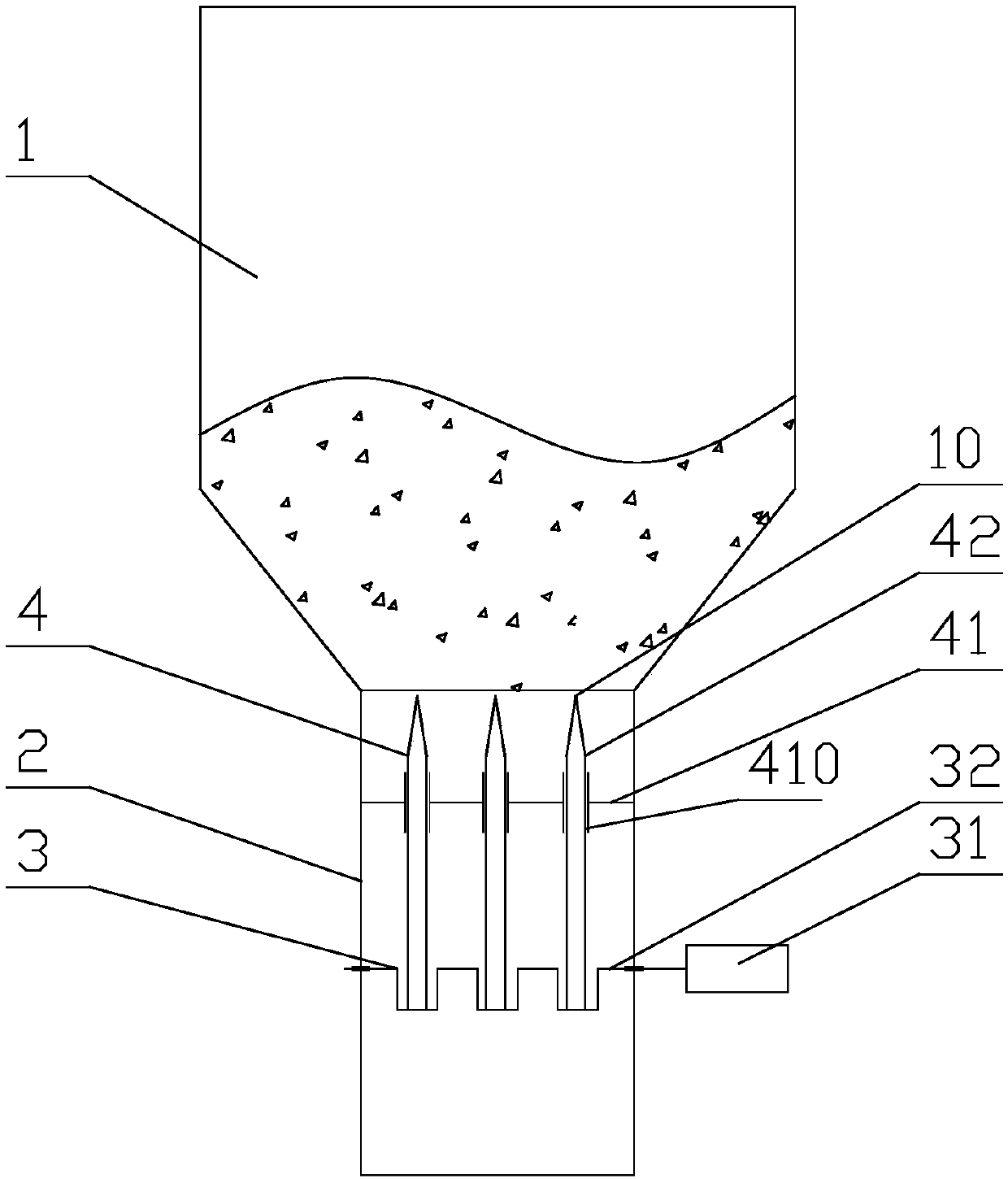

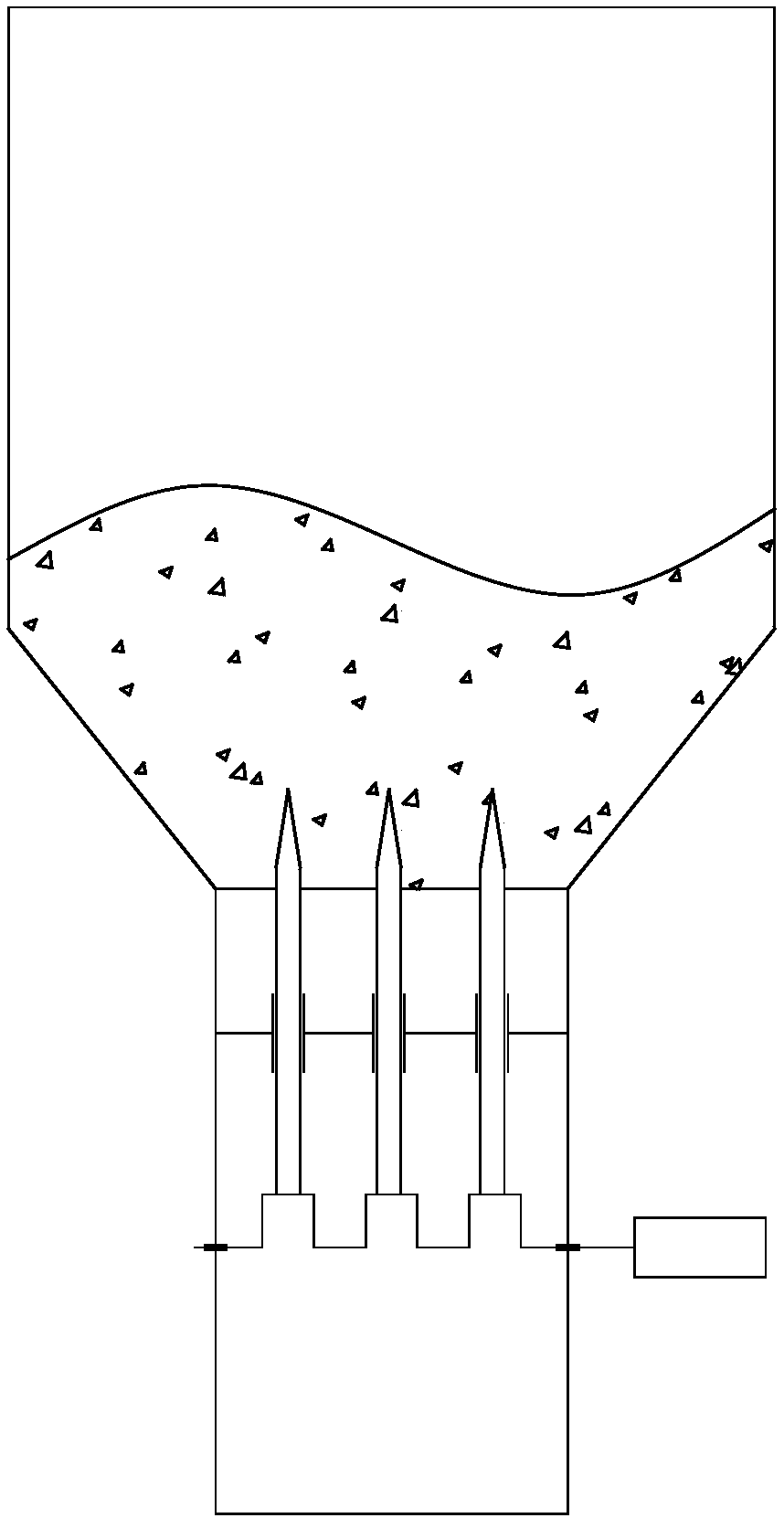

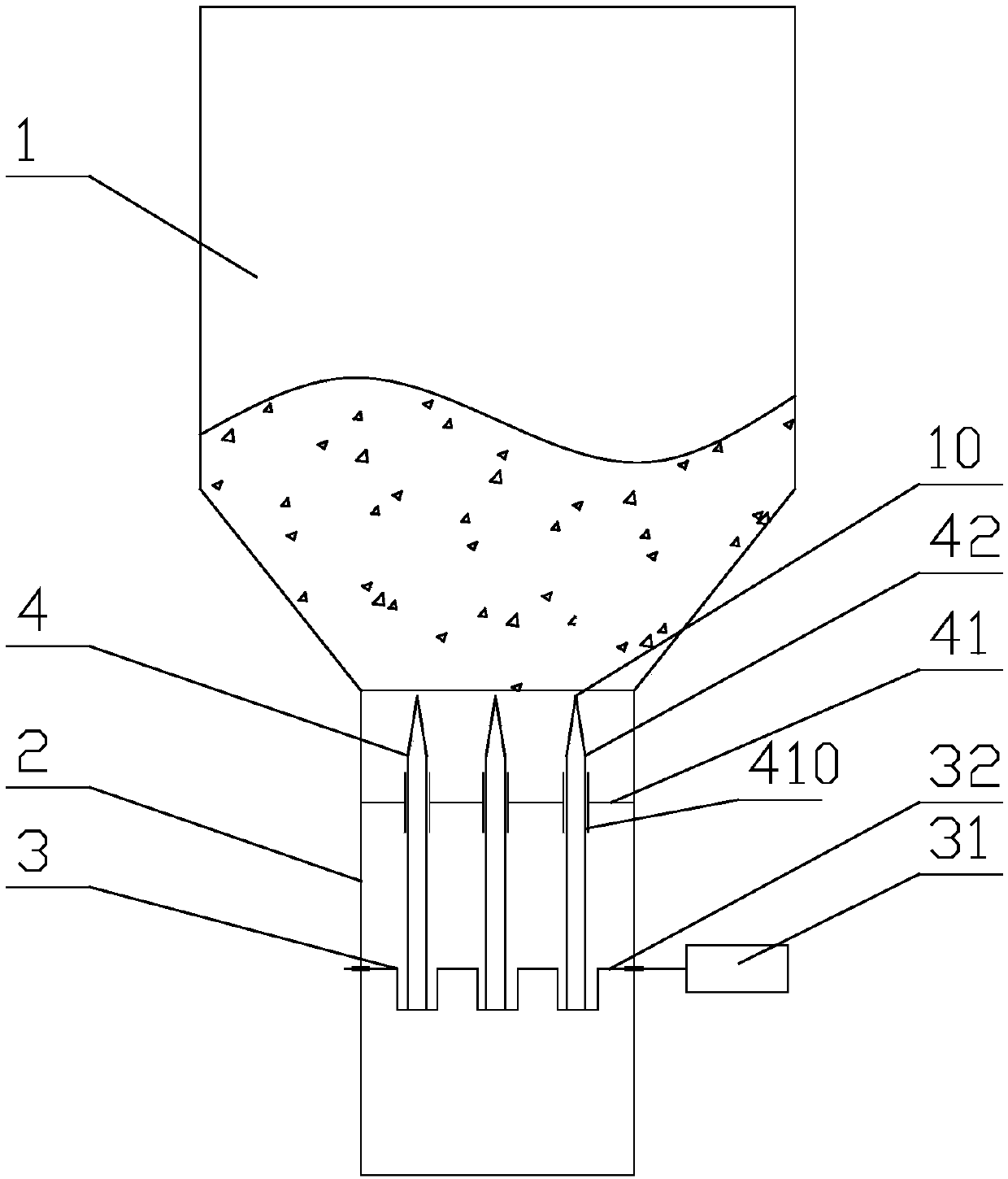

[0014] The present invention as Figure 1-2 As shown, it is connected below the discharge port 10 of the discharge device 1 of the zinc oxide production line, including the cylinder body 2, the drive device 3 and the execution device 4;

[0015] The cylinder body 2 is detachably connected below the discharge port and has the same diameter as the discharge port 10;

[0016] The driving device 3 includes a motor 31 arranged outside the cylinder body 2 and a crankshaft 32 arranged radially along the cylinder body 2. The crankshaft 32 passes through the cylinder body 2 and is movably connected with the cylinder body 2. The motor 31 drives the crankshaft 32 to rotate;

[0017] The execution device 4 includes a bracket 41 and a plurality of thimbles 42, the bracket 41 is fixedly connected in the cylinder body 2, and a plurality of through holes 410 are opened on the bracket 41, and the thimbles 42 are movably connected in the through holes 410, And erected on the crankshaft 32 , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com