Automobile part transfer device

A technology for transfer devices and auto parts, which is applied in transportation and packaging, trolleys, motor vehicles, etc., can solve the problems of a large number of manual interventions and low degree of automation, and achieve the effect of improving the degree of mechanical automation, improving transfer efficiency, and ensuring linkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

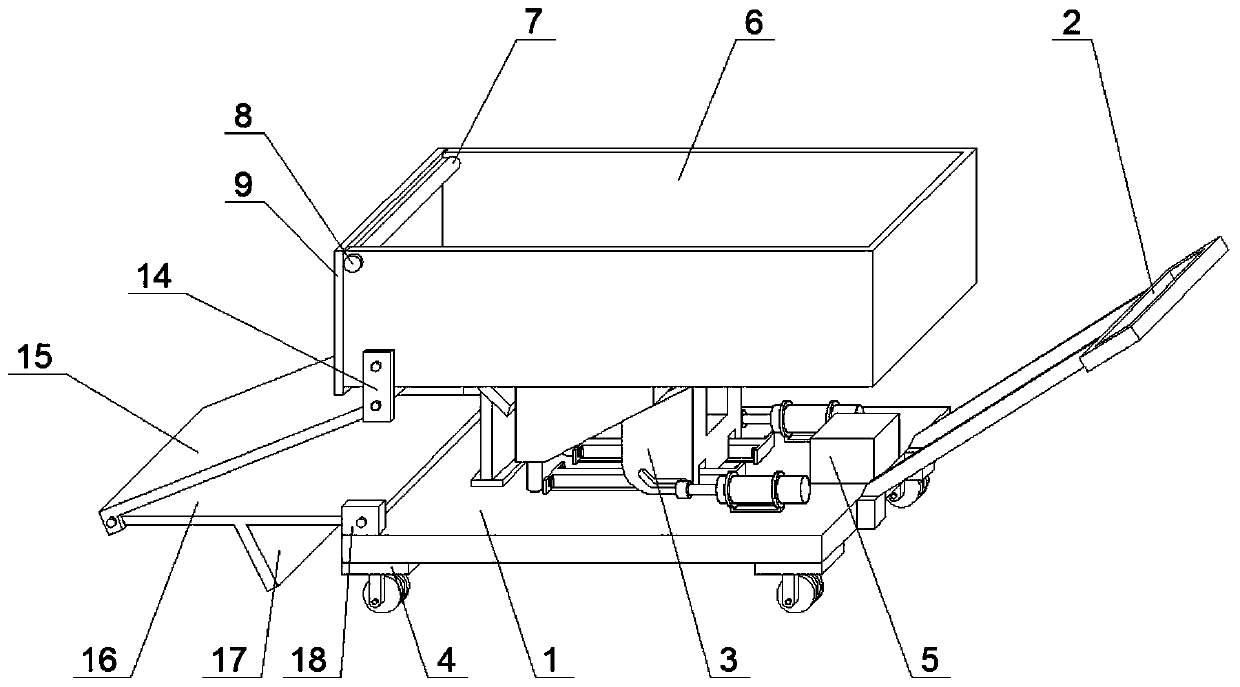

[0022] Such as Figure 1 ~ Figure 3 As shown, the auto parts transfer device provided in this embodiment includes a mobile chassis 1 and a plurality of universal rollers 4 arranged on the lower surface of the mobile chassis 1. A parts storage box 6 is installed on the mobile chassis 1, and one side of the mobile chassis 1 A push-pull handle 2 is fixed, and a supporting mechanism is arranged between the other side of the mobile chassis 1 and the parts storage box 6 .

[0023] A lifting steering mechanism 3 is installed between the mobile chassis 1 and the parts storage box 6. The lifting steering mechanism 3 includes a slide rail 33, a slide table 31, a loading platform 32, two supporting columns 34 and two groups of driving mechanisms. There are two groups of slide rails 33, and the two groups of slide rails 33 are all fixed on the mobile chassis 1 and arranged parallel to each other. The two ends of the slide rails 33 are all provided with limiting plates 39, and the limiting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com