A flame-retardant anti-virus anti-chemical fabric and its manufacturing method

A manufacturing method and fabric technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., to achieve excellent protection ability, wide application and market prospects, good anti-toxicity and anti-hazardous chemical permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The first step, the preparation of the outer layer 1;

[0039] Fully mix polyolefin resin and polyolefin flame retardant at a weight ratio of 100:5-30 to obtain a mixed raw material; then extrude the mixed raw material through a film blowing machine or a casting machine, and the extrusion temperature is 160-220°C. The extrusion speed is 5-30m / min to obtain the outer layer 1;

[0040] The polyolefin flame retardant is decabromodiphenyl ether, ammonium polyphosphate or phosphoric acid ester;

[0041] The second step, the preparation of the middle layer;

[0042] (1) Preparation of flame-retardant fabric-21: using at least one of flame-retardant polyester fiber, flame-retardant acrylic fiber, flame-retardant vinylon or flame-retardant nylon to obtain flame-retardant fabric-21 through a weaving process;

[0043] (2) Preparation of flame-retardant fabric 222: using at least one of flame-retardant viscose fiber, para-aramid fiber, meta-aramid fiber, polyarylene oxadiazole f...

Embodiment 1

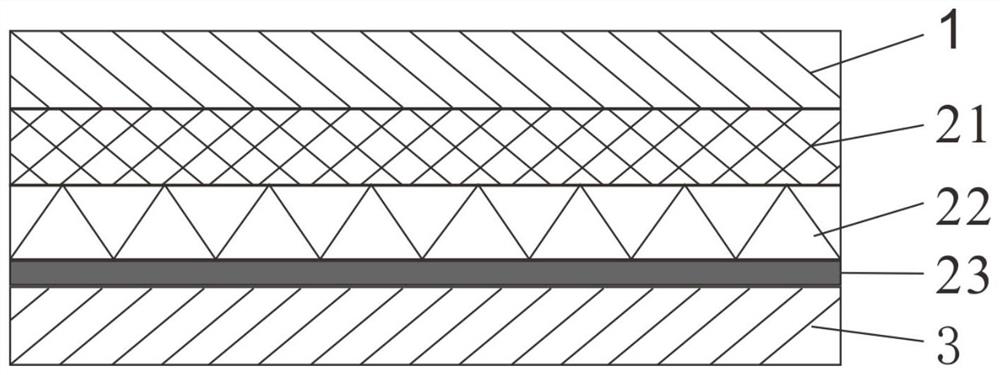

[0061] A flame-retardant, anti-virus and chemical-resistant fabric is characterized in that the fabric includes an outer layer 1, a middle layer and an inner layer 3 from the outside to the inside, and its structure is as follows: figure 1 shown;

[0062] The outer layer 1 is made of 100 parts by weight polyolefin resin and 6 parts by weight polyolefin flame retardant blended blown film, and the polyolefin resin is blended by 100 parts by weight linear low density polyethylene resin and 50 parts by weight polyolefin plastomer resin Composition, the flame retardant is decabromodiphenyl ether, the extrusion temperature is 170°C, and the extrusion speed is 5m / min to obtain the outer layer 1.

[0063] The middle layer is made of flame-retardant fabric 1 21, flame-retardant fabric 2 22 and polyhalogenated olefin film 23 by compounding, and the structure is arranged from outside to inside as flame-retardant fabric 1 21 / flame-retardant fabric 2 22 / polyhalogen Olefin film 23; fla...

Embodiment 2

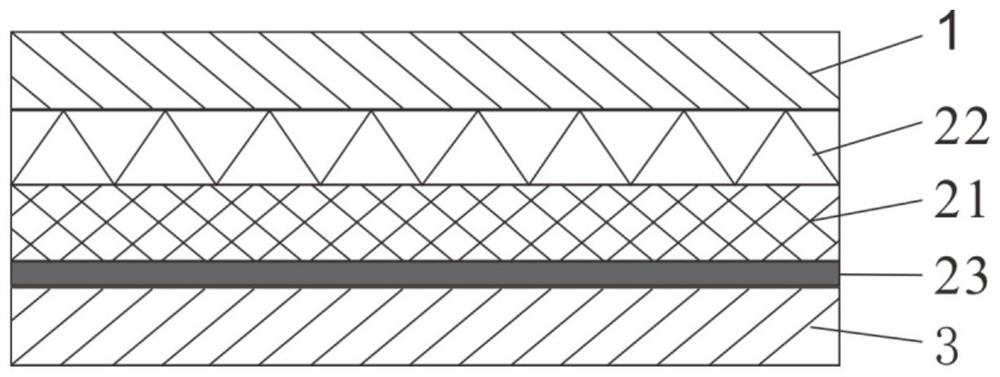

[0068] A flame-retardant, anti-virus and chemical-resistant fabric is characterized in that the fabric includes an outer layer 1, a middle layer and an inner layer 3 from the outside to the inside, and its structure is as follows: figure 2 shown;

[0069] The outer layer 1 is made of 100 parts by weight of polyolefin resin and 28 parts by weight of polyolefin flame retardant blended blown film, and the polyolefin resin is composed of 100 parts by weight of low density polyethylene resin and 100 parts by weight of polypropylene homopolymer resin , the flame retardant is ammonium polyphosphate, the extrusion temperature is 195°C, and the extrusion speed is 25m / min to obtain the outer layer 1.

[0070] The middle layer is made of flame-retardant fabric 1 21, flame-retardant fabric 2 22 and polyhalogenated olefin film 23 by compounding, and the structure is arranged from outside to inside as flame-retardant fabric 2 22 / flame-retardant fabric 1 21 / polyhalogenated Olefin film 23; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com