Auxiliary loading device for simulating stress diffusion effects of pavement layer and application method

A technology of diffusion and loading devices, which is applied in the direction of measuring devices, using repeated force/pulsation force to test the strength of materials, instruments, etc., can solve the problems of uneconomical, high power, difficult to achieve repeated rolling of asphalt concrete, etc., to achieve Effects of improving precision and simplifying test conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

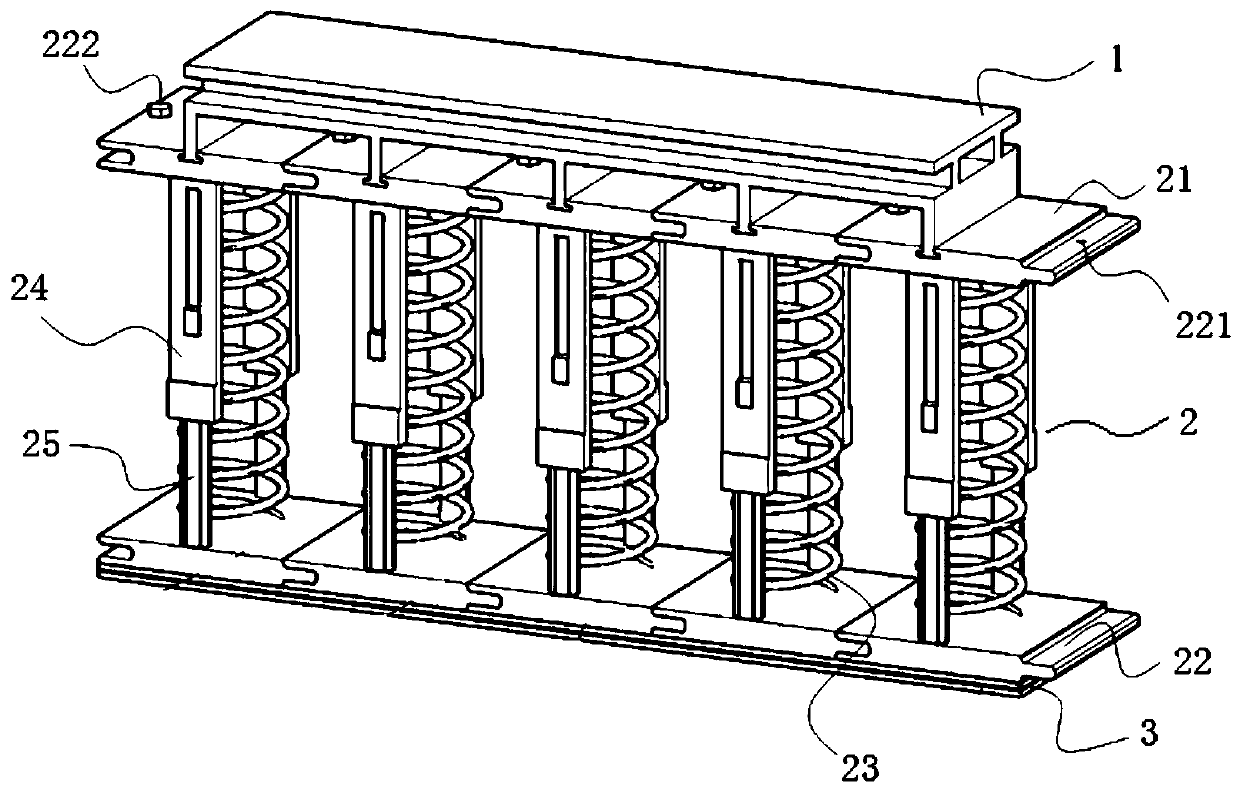

[0047] see Figure 1 to Figure 10 , the auxiliary loading device for simulating the stress diffusion of pavement layers according to an embodiment of the present invention includes a load distribution system, a load transfer system and a viscoelastic contact simulation system connected in sequence.

[0048]The load distribution system includes a horizontal load distribution beam 1 capable of distributing loads to the load transfer system, and is provided with several vertical and horizontal stiffeners.

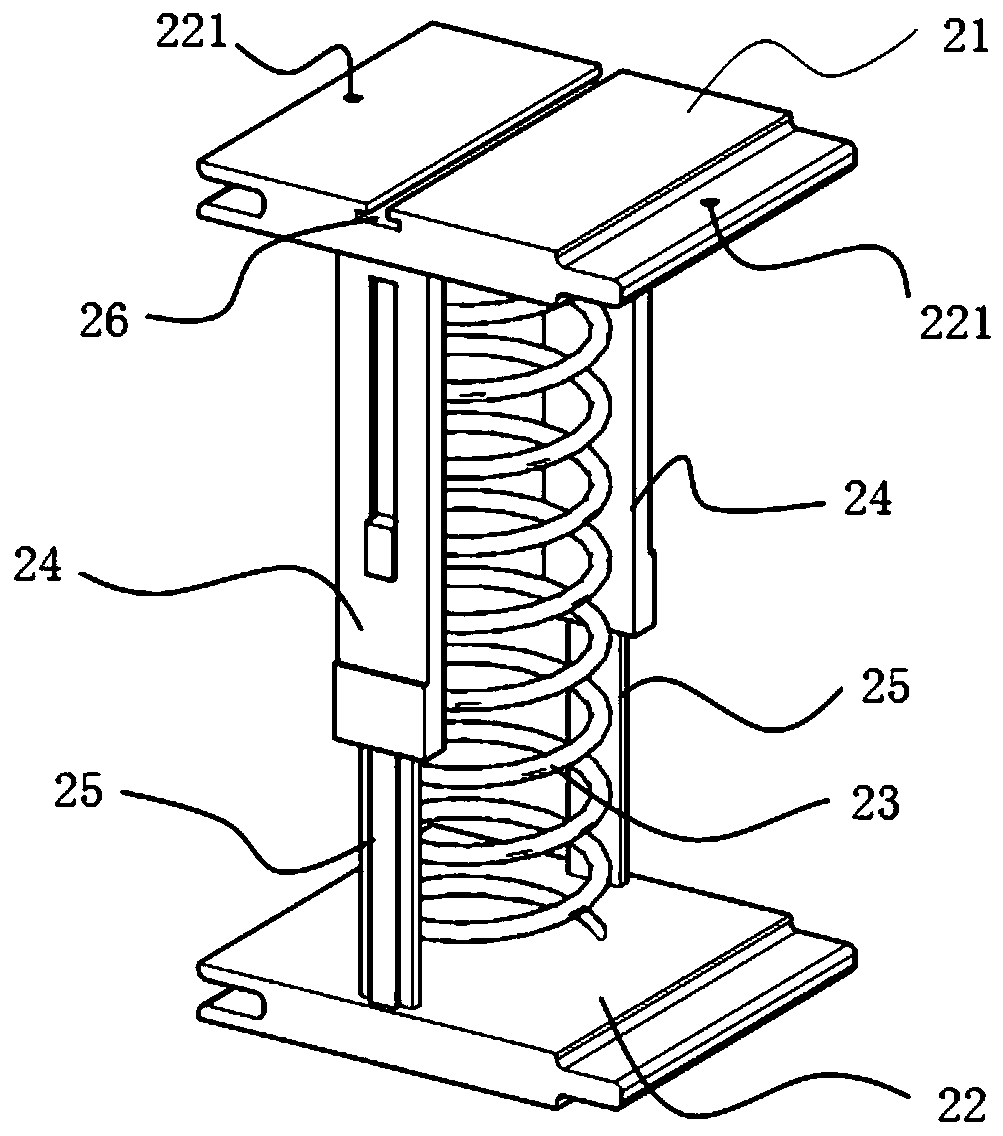

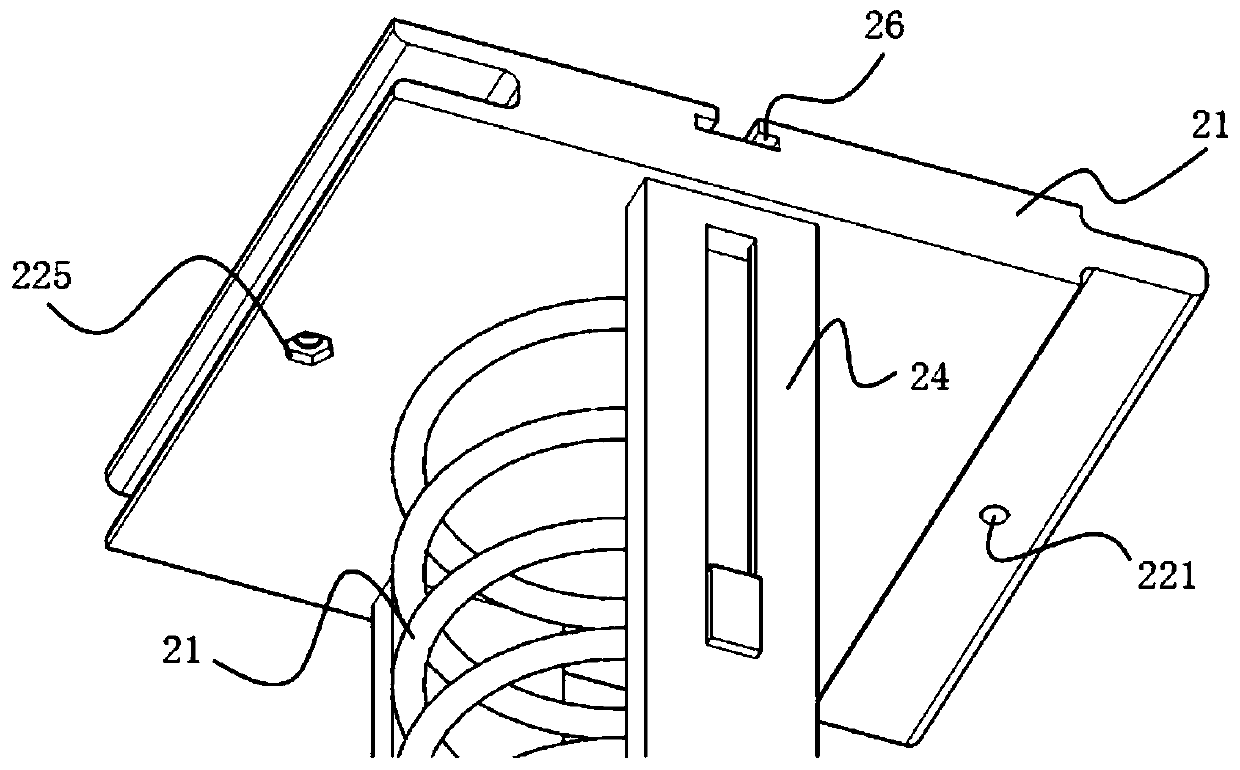

[0049] The load transfer system includes an odd number of laterally connected load transfer devices 2 in sequence, and each load transfer device 2 includes a connecting top plate 21 connected to the load distribution beam, a hinged bottom plate 22 connected to the viscoelastic contact simulation system, and a connecting top plate 21 and The force-transmitting elastic member 23 between the hinged base plates 22 is preferably a force-transmitting spring. The stiffness coefficien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com