Valve assembly for an injection valve and injection valve

A technology of valve components and injection valves, applied in fuel injection devices, special fuel injection devices, engine components, etc., can solve the problems of needle bounce, low stiffness, buckling, etc., and achieve the effects of reducing needle bounce, low cost, and maintaining emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

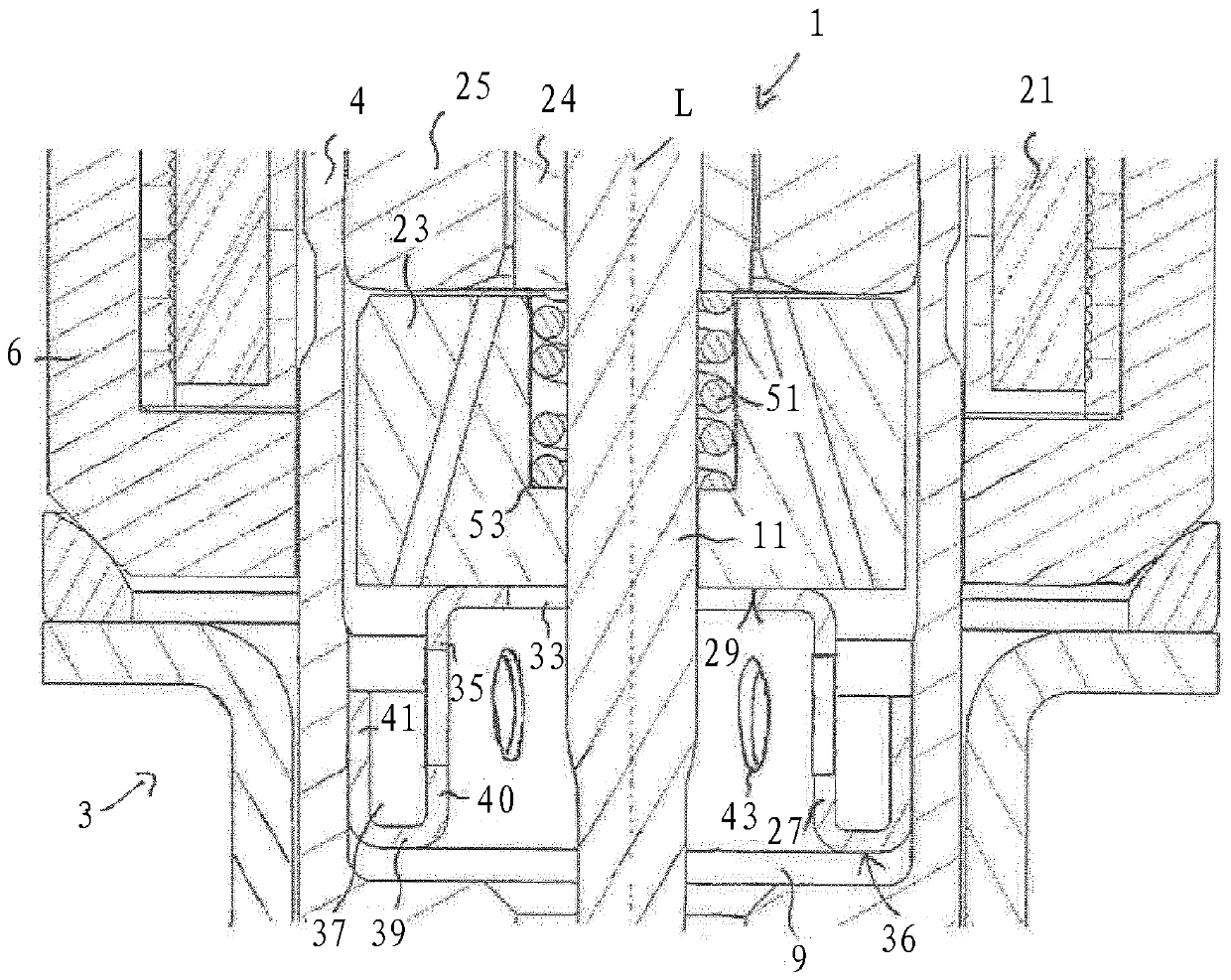

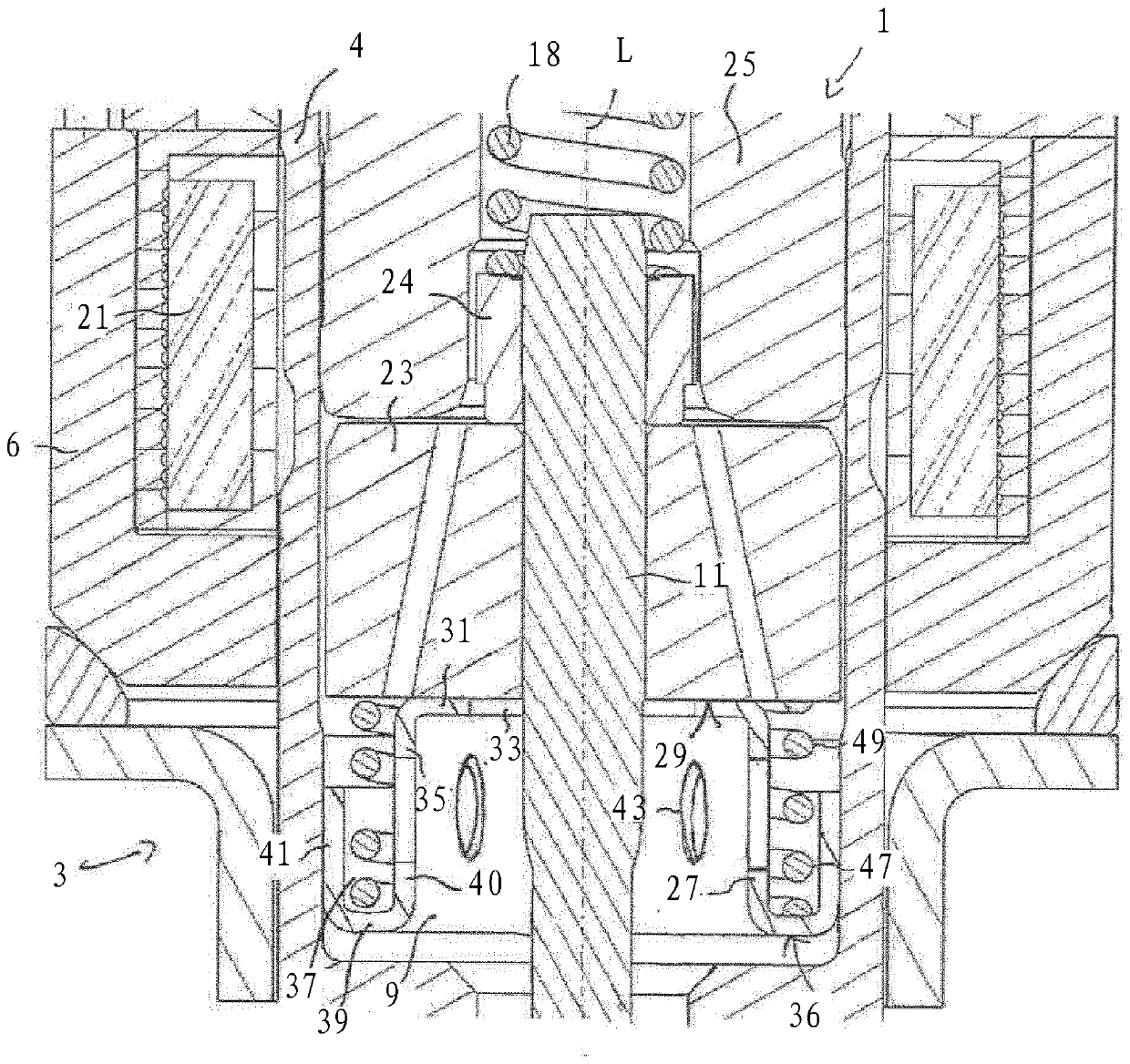

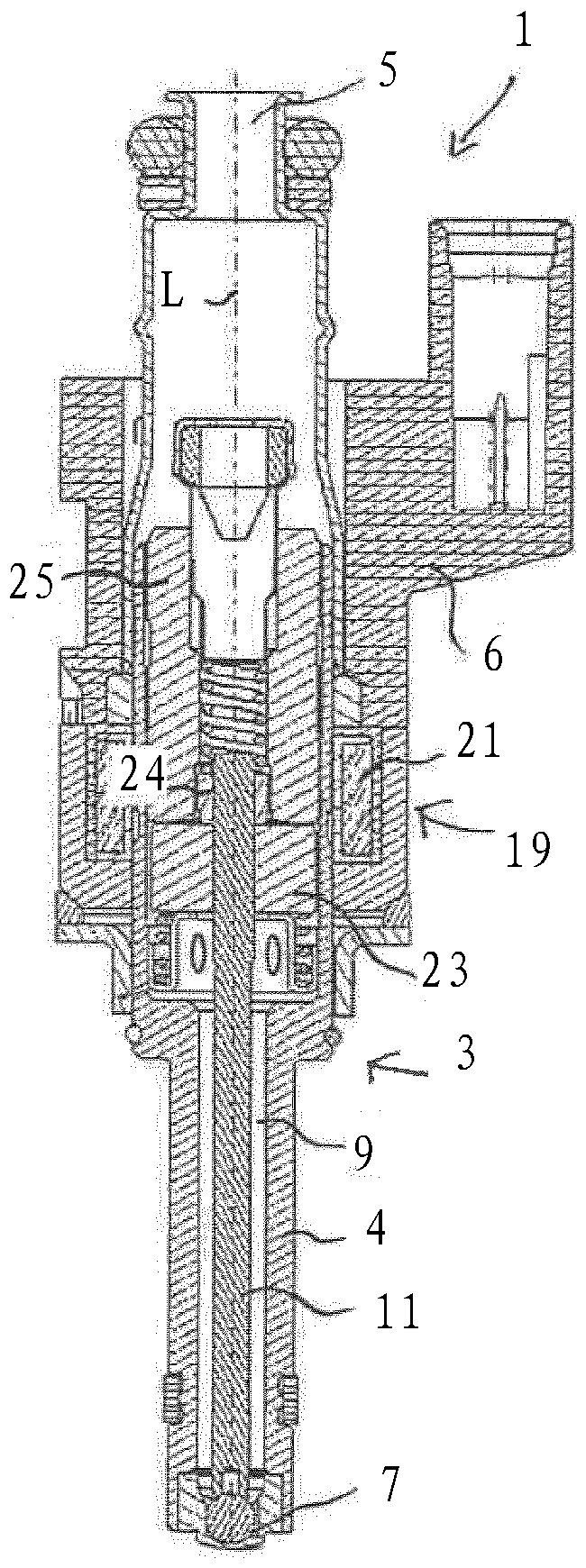

[0036] Such as figure 1 and 2 The fluid injection valve 1 shown in is particularly suitable for metering fuel to combustion engines. However, the invention can also be used for other types of injection valves.

[0037] Injection valve 1 includes a valve assembly 3 . The valve assembly 3 comprises a valve body 4 having a central longitudinal axis L. As shown in FIG. The housing 6 is arranged partially around the valve body 4 .

[0038]The valve body 4 includes a chamber 9 . The chamber 9 has a fluid outlet portion 7 . The fluid outlet portion 7 communicates with the fluid inlet portion 5 provided in the valve body 4 . The fluid inlet portion 5 and the fluid outlet portion 7 are in particular positioned at opposite axial ends of the valve body 4 . Chamber 9 receives valve needle 11 . The valve needle 11 includes a needle shaft and a sealing ball welded to the end of the needle shaft.

[0039] In the closed position of the valve needle 11 , the sealing ball rests sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com