Bearing device for vehicle wheel

A bearing device and wheel technology, applied in the direction of wheel bearings, bearings, axles, etc., can solve the problems of enlarging weirs, replacing wheel hub bolts, etc., and achieve the effects of eliminating sealing, easy replacement operations, and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

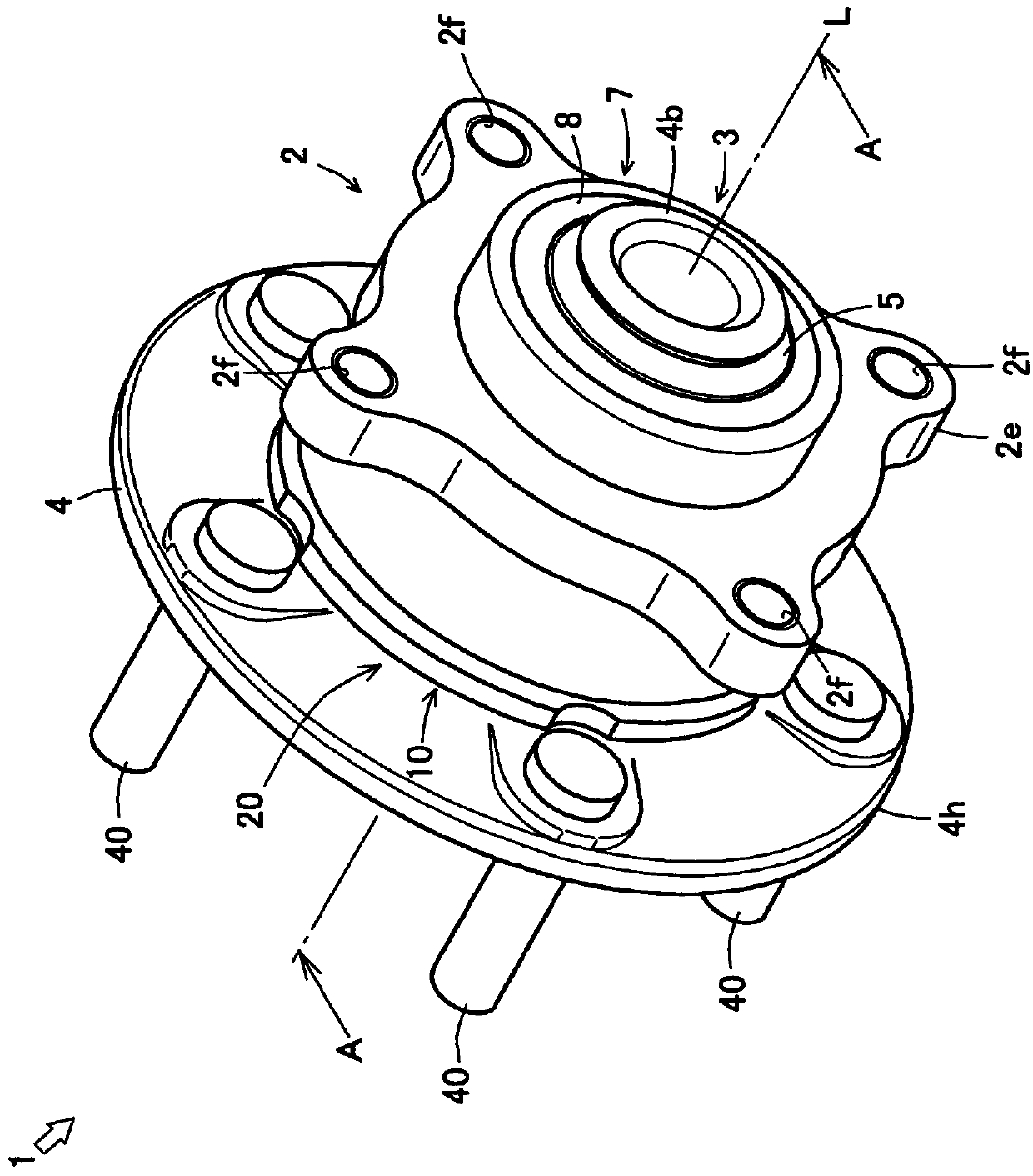

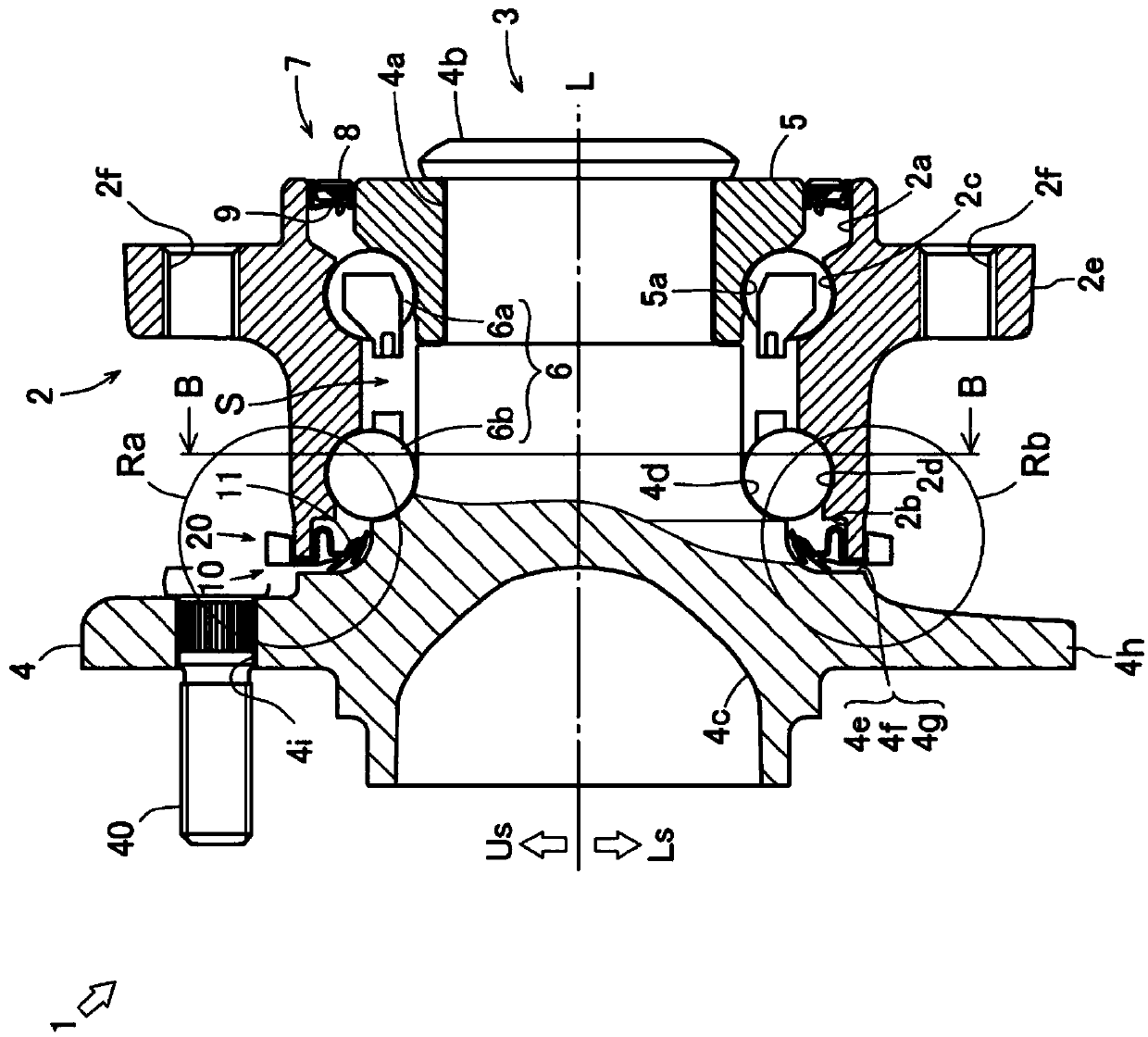

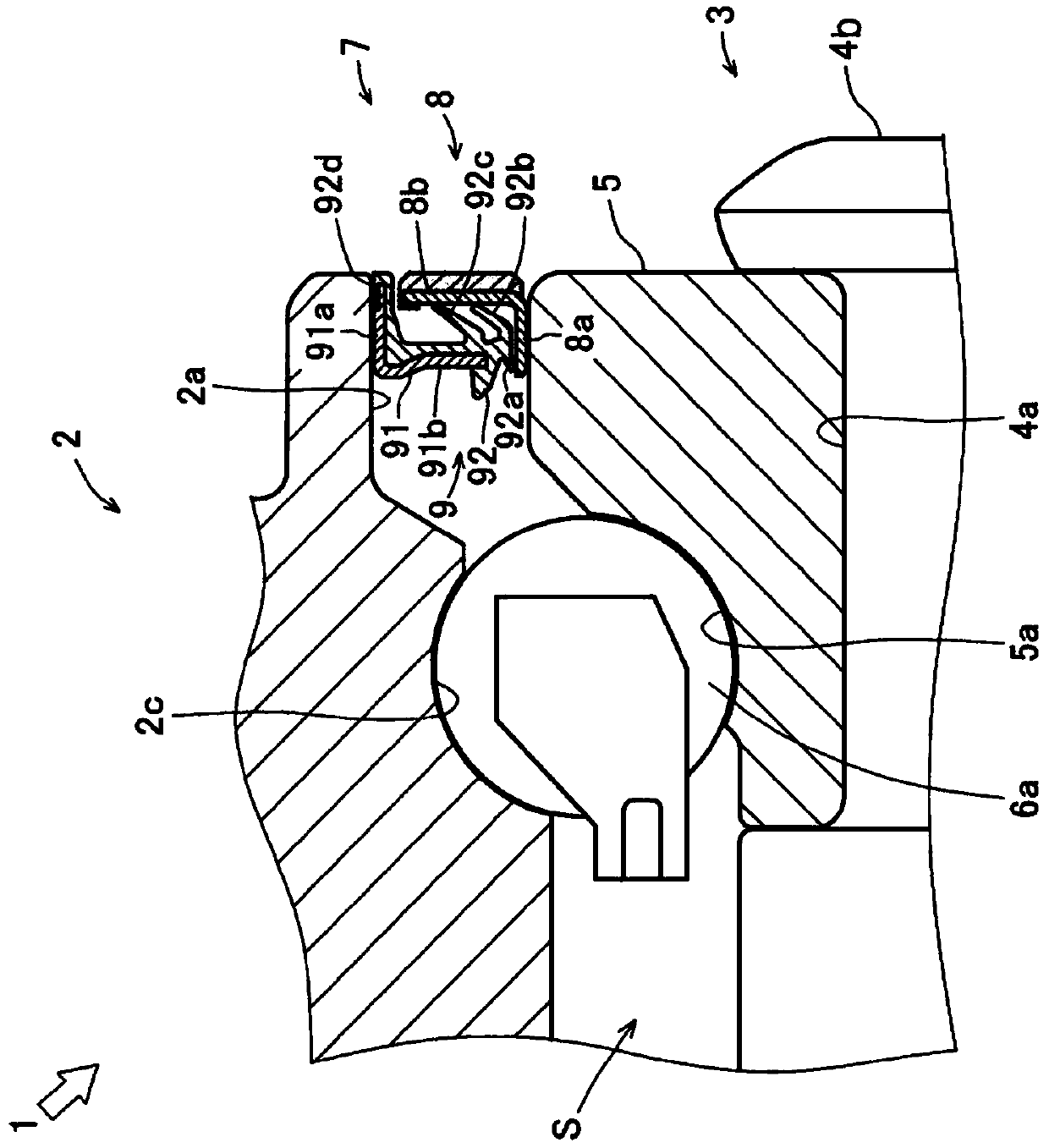

[0081] Below, use Figure 1 to Figure 4 The wheel bearing device 1 of the present invention will be described. figure 1 It is a perspective view of the bearing device 1 such as a wheel. figure 2 of figure 1 A-A sectional view in . image 3 as well as Figure 4 yes figure 2 Enlarged view of a local area in .

[0082] The wheel bearing device 1 rotatably supports a wheel in a suspension device of an automobile or the like. The wheel bearing device 1 includes an outer member 2, an inner member 3 (a hub 4 and an inner ring 5), rolling elements 6, a seal member 7 (hereinafter referred to as "inner seal member 7"), and a seal member 10 (hereinafter referred to as "inner seal member 7"), and a seal member 10 (hereinafter referred to as " Outer sealing member 10"). Here, the inner side indicates the vehicle body side of the wheel bearing device 1 when mounted on the vehicle body, and the outer side indicates the wheel side of the wheel bearing device 1 when mounted on the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com