Sheet bonding material and magnetic workpiece and preparation method and application thereof

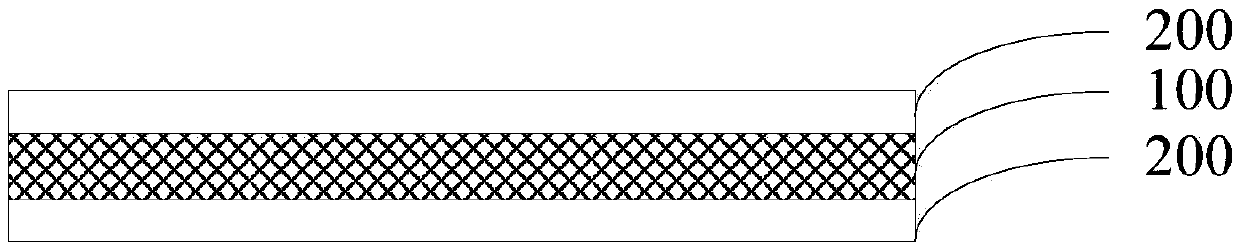

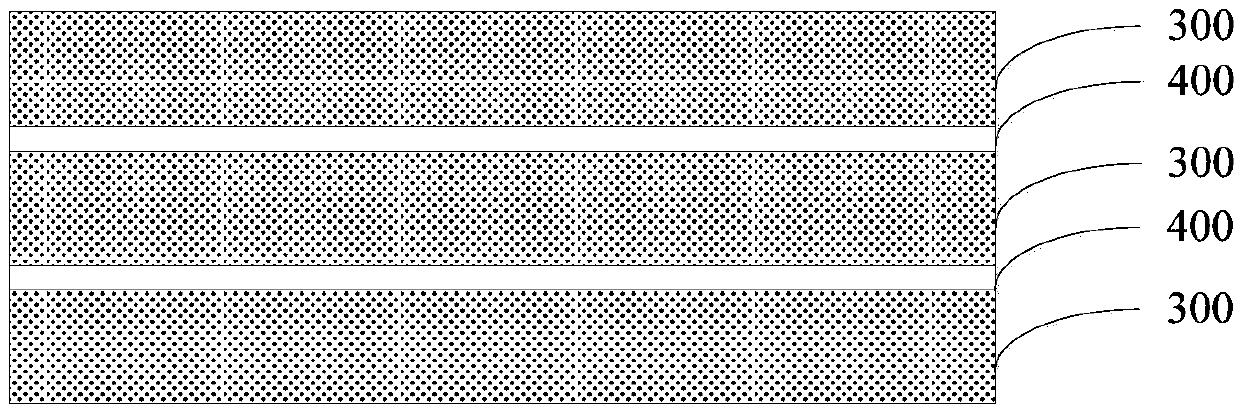

A bonding material and sheet-like technology, which is applied in the direction of film/sheet-like adhesives, magnetic objects, inductors/transformers/magnets, etc., can solve the problem of motor temperature rise, energy loss, and low service life of motor magnets And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

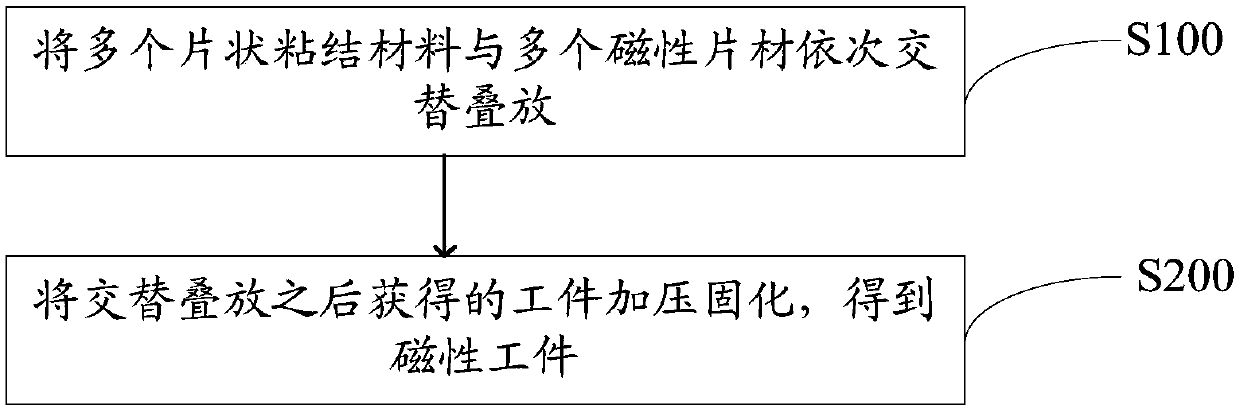

Method used

Image

Examples

Embodiment 1-7

[0095] In the magnetic workpieces of Examples 1-7, the insulating layer of the sheet-like bonding material is glass fiber woven fabric, and the glue layer is epoxy resin glue. The difference is that the thickness and content of the insulating layer and the glue layer are different. For details, refer to the table 1:

[0096] Table 1

[0097]

[0098]

[0099] The result that utilizes the magnetic workpiece of embodiment 1-7 to test can refer to table 2:

[0100] Table 2

[0101]

Embodiment 8

[0103] In this embodiment, the structure of the magnetic workpiece is the same as in Embodiment 4, except that the thickness of the insulating layer is 0.01 mm.

[0104] The shear strength of the magnetic workpiece of this embodiment is 57.4P / MPa. When the insulation effect of the adhesive layer is tested with a digital multimeter, there is a beeping sound, which shows that the magnetic workpiece is conductive. The main reason is that the thickness of the insulating layer is not enough, and the prepared The adhesive layer is easy to be squeezed out when the workpiece is magnetic, and it is difficult to ensure that the thickness of the adhesive layer is consistent.

Embodiment 9

[0106] In this embodiment, the structure of the magnetic workpiece is the same as in Embodiment 4, except that the content of the glue layer is 60 wt%.

[0107] The shear strength of the magnetic workpiece in this embodiment is 60.4P / MPa, and the insulation effect test result is infinite / no sound. However, because the cost of the glue is relatively high, the content of the glue layer is too high, it is partially extruded during the pressure curing process, and the thickness of the adhesive layer is thick, the consistency of the magnetic properties of the product becomes poor, resulting in a relatively large increase in cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com