An installation structure of an L-shaped lock foot anchor rod

A technology for locking the anchor rod and installing structure, which is applied in the direction of installation of anchor rod, mining equipment, earth-moving drilling, etc., can solve the problems of inability to weld, difficult operation, low efficiency, etc., and achieve the effect of not easy to damage and fail.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

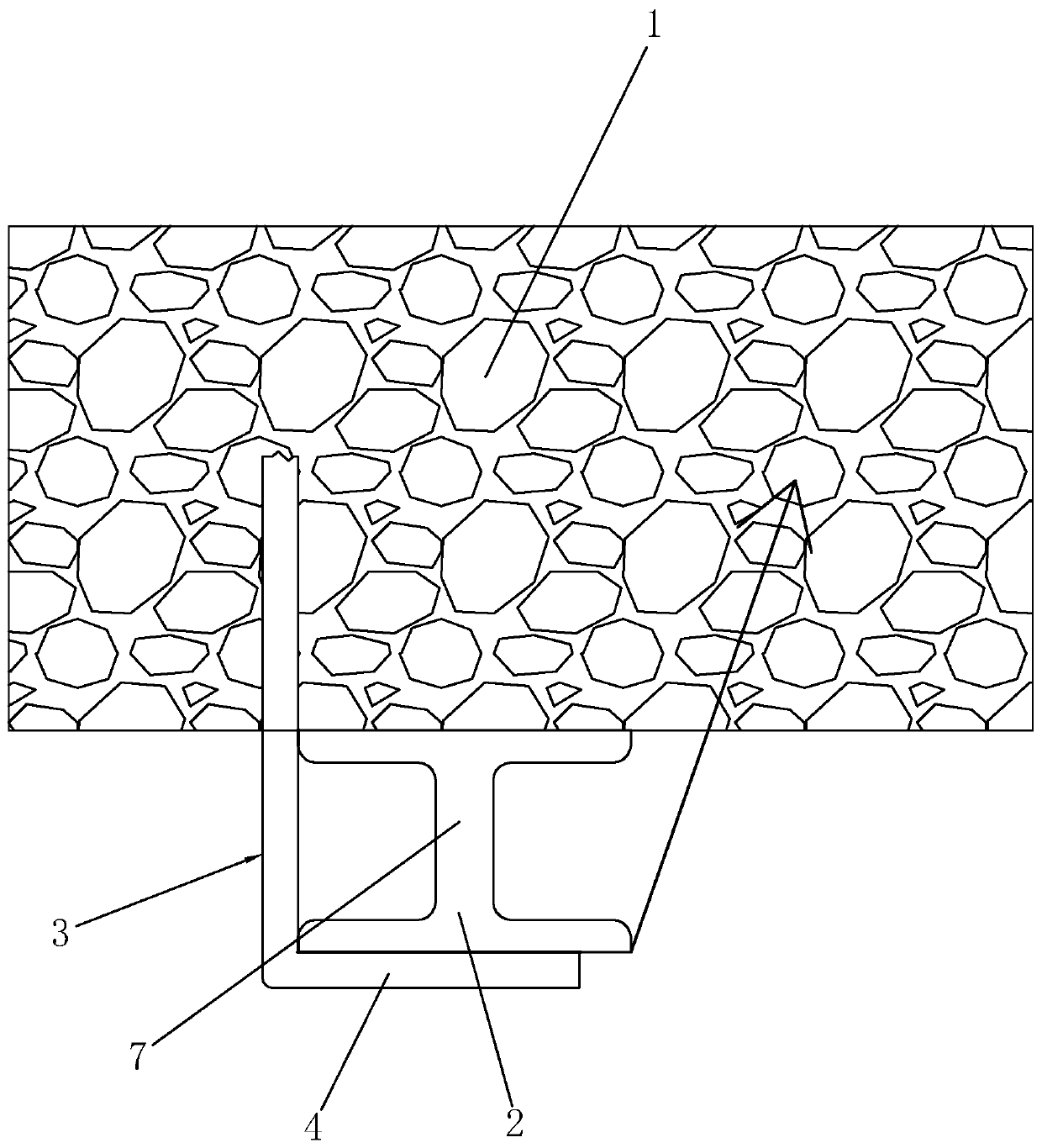

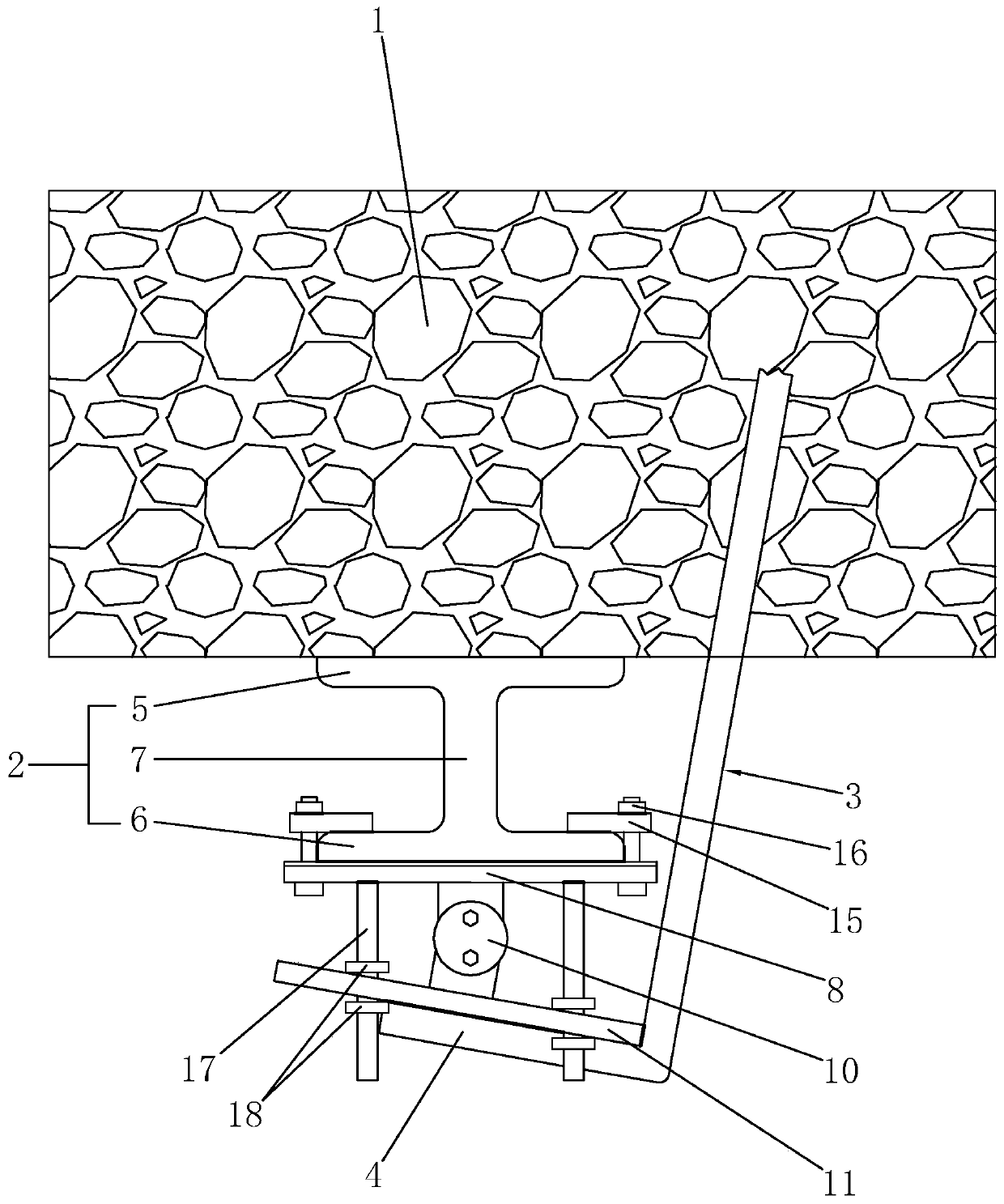

[0031] A kind of installation structure of L-shaped locking foot bolt, such as figure 2 As shown, it includes surrounding rock layer 1, steel arch frame 2, and L-shaped locking foot anchor rod 3; L-shaped locking foot anchor rod 3 includes a rod part and a tail end 4 perpendicular to the rod part; steel arch frame 2 adopts H-shaped steel Manufactured; the steel arch 2 includes an inner panel 5 facing the side of the surrounding rock layer 1, an outer panel 6 on the side away from the surrounding rock layer 1, and a side panel 7 connecting the inner panel 5 and the outer panel 6. The L-shaped locking foot bolt 3 is prefabricated in a factory and can be mass-produced.

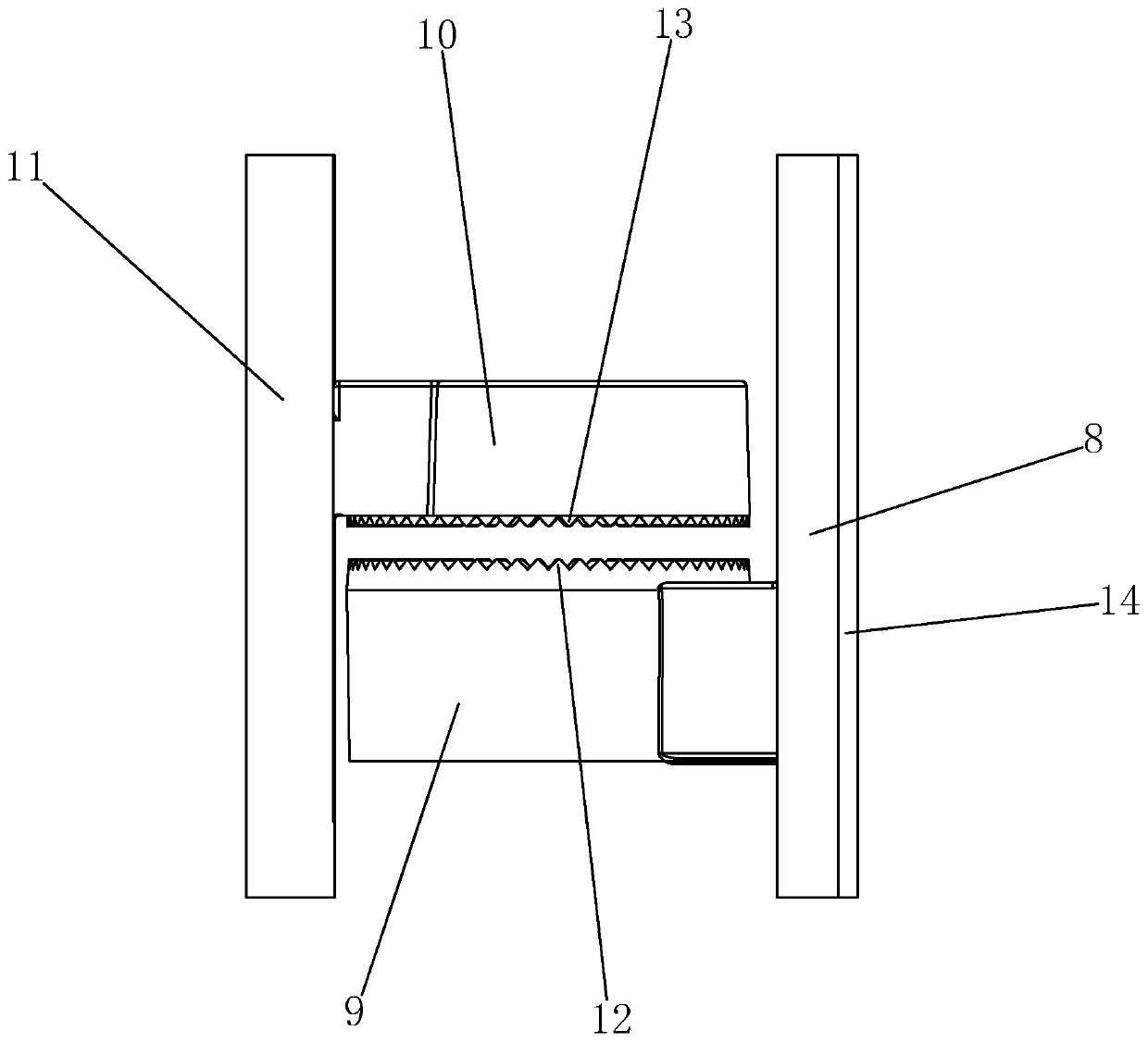

[0032] Such as Figure 2-3 As shown, it also includes a regulator of steel structure, the regulator includes a mounting plate 8, the mounting plate 8 is fixedly connected with the side of the steel arch 2 facing away from the surrounding rock layer 1, the mounting plate 8 is fixedly connected with a rotating se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com