Formwork trolley for tunnel side wall secondary lining pouring and arch crown precast segment transferring

A formwork trolley and wall formwork technology, applied in tunnel lining, tunnel, shaft lining, etc., can solve the problem of long preparation time, and achieve the effect of convenient positioning and demoulding, convenient installation and convenient transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

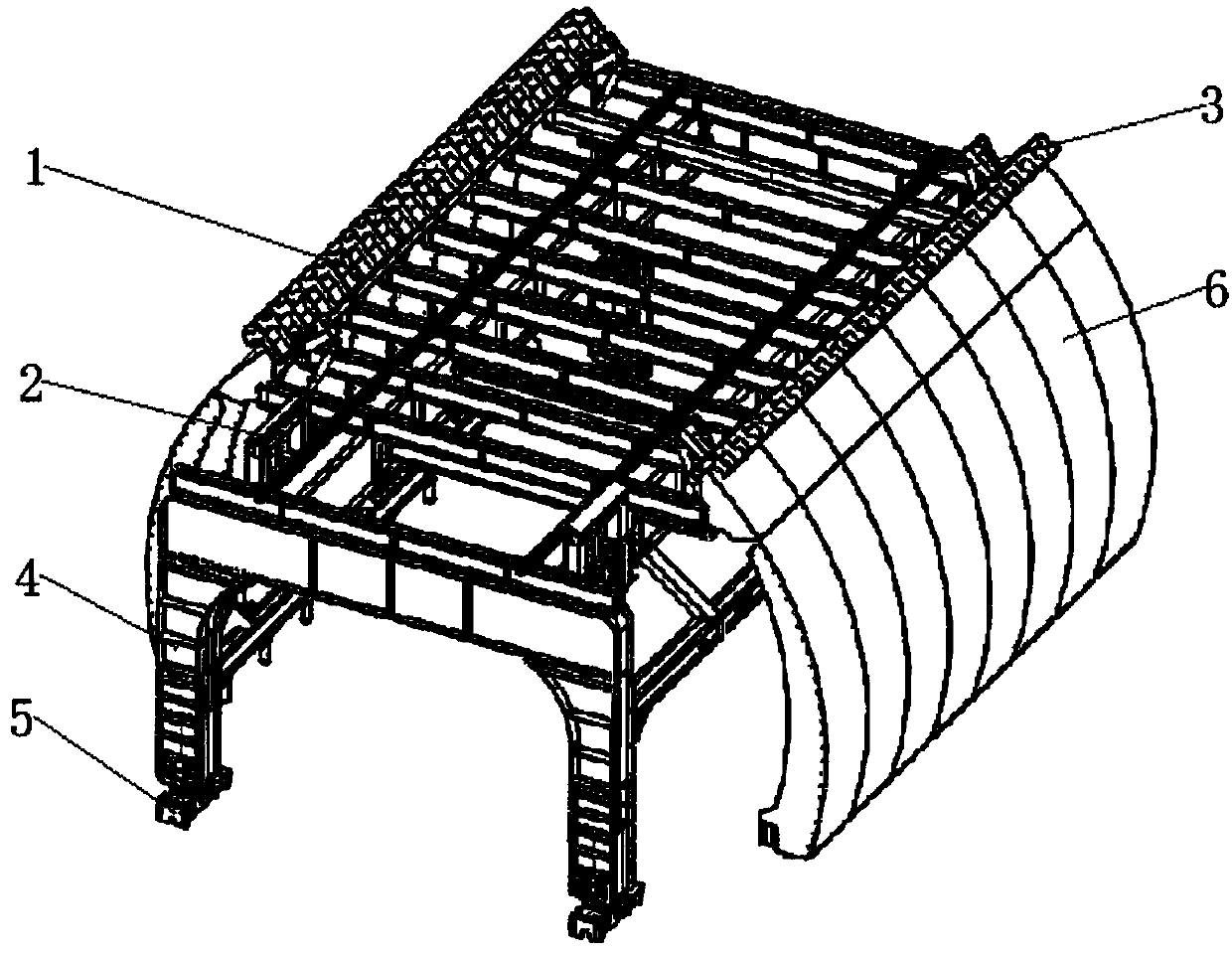

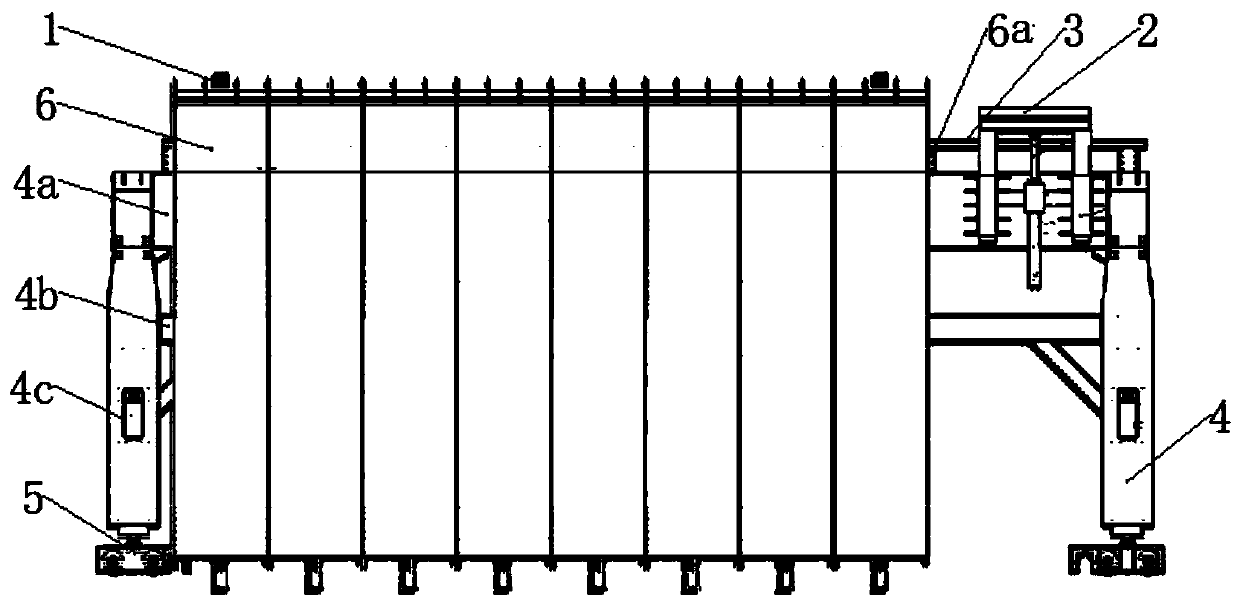

[0041] This embodiment discloses a formwork trolley for pouring the second lining of the side wall of the tunnel and transferring the prefabricated segment of the vault, such as figure 1 , figure 2 As shown, the formwork trolley body 4 is included, and the formwork trolley body 4 is used as the overall frame of the whole trolley, on which various functional institutions or units can be arranged, and its realization forms are various.

[0042] In this embodiment, the formwork trolley body 4 specifically includes portal frames 4c arranged at both ends of the front and rear. The longitudinal direction of the car is in the same direction as the tunnel length direction.

[0043] The two masts 4c are respectively connected by the upper longitudinal beam 4a of the mast and the lower longitudinal beam 4b of the mast. Both the upper longitudinal beam 4a of the mast and the lower longitudinal beam 4b of the mast are two, and are symmetrically arranged on the mast 4c , the two upper l...

Embodiment 2

[0058] In this embodiment, other parts are the same as Embodiment 1. The longitudinal seam end die mechanism 1 also includes the following contents:

[0059] Such as image 3 , 4 , 5 and 6 show that the above-mentioned raised portion comprises a vertical plate 1h vertically connected to the end of the contact plate 1g, and the direction of the vertical plate 1h is consistent with the edge of the end of the contact plate 1g; the end of the vertical plate 1h is connected with The slot template 1a perpendicular to it, and the slot template 1a is positioned at the opposite side of the contact plate 1g; the shape of the slot template 1a is two parts connected as one, and the part away from the vertical plate 1h is positioned at the top of the part near the vertical plate 1h; when contact When the plate 1g covers the upper part of the end of the side wall formwork mechanism 6, the vertical plate 1h and the groove formwork 1a are located near the side wall of the tunnel, and the en...

Embodiment 3

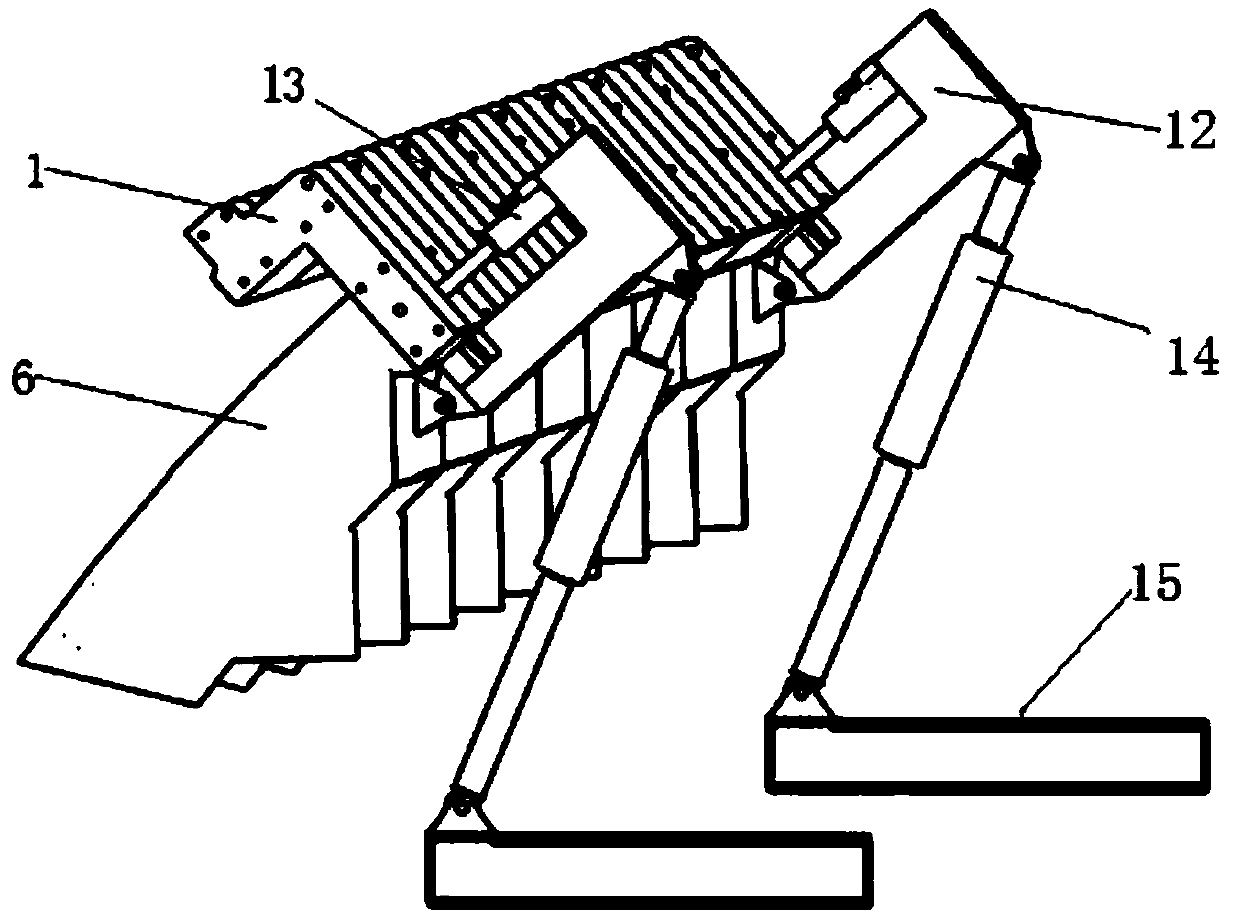

[0079] In this embodiment, other parts are the same as Embodiment 1. In this embodiment, the jacking device also has the following characteristics, such as Figure 10 As shown, the device is arranged on both sides of the trolley body 4, and the trolley body 4 is used as the overall frame of the whole trolley, on which various functional institutions or units can be arranged, and its realization forms are various. The trolley 1 is used To realize the pouring of the second lining of the side wall of the tunnel and the transfer of the prefabricated segment 8 of the vault. Therefore, the two sides along the tunnel excavation direction are called both ends, and the two sides perpendicular to the tunnel excavation direction are called two sides. The invention lifts the segment 8 to a designated position for subsequent transportation and installation of the trolley.

[0080] Such as Figure 7 As shown, the two guide pieces 2a arranged oppositely are fixedly connected with the troll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com