A Method for Determining the Optimal Scheme of Making Regenerated Aggregate Products

A technology of recycled aggregates and the best solution, applied in the field of determining the best solution for the preparation of recycled aggregate products, can solve the problems of complicated experiments, high economical and time-cost of recycled aggregate products, improve the experimental speed, protect the environment, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for determining the best solution for preparing recycled aggregate products, the specific steps are as follows:

[0023] (1) Determine the influencing factor x 1 、x 2 、x 3..... x n , n≥4, where the influencing factor x 1 Set as the particle size of recycled aggregate;

[0024] (2) Influencing factor x in step (1) 1 Recycled aggregate is recycled concrete aggregate or recycled brick aggregate or a mixture of recycled concrete aggregate and recycled brick aggregate in any ratio. The particle size is divided into 6 grades according to the national standard, respectively 4.75-9.5mm, 4.75 -16mm, 4.75-19mm, 4.75-26.5mm, 4.75-31.5mm, 4.75-37.5mm, select 4 or more levels continuously from the first level among the 6 levels, and take other influencing factors x i Evenly divided into groups with the same number of grades, 1<i≤n; other influencing factors are the ratio of natural aggregates replaced by recycled aggregates, the ratio of recycled concrete aggregates ...

Embodiment 2

[0028] A method for determining the best solution for preparing recycled aggregate products, the specific steps are as follows:

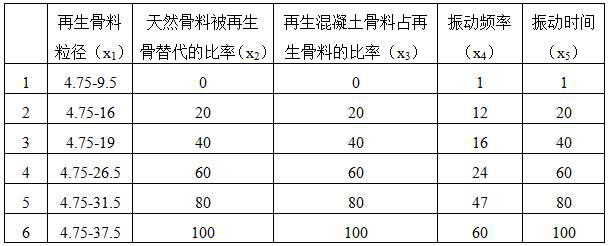

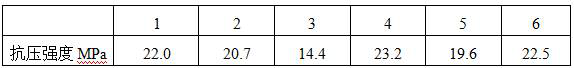

[0029] (1) Determine the influencing factors as the particle size of recycled aggregate (x 1 ), the ratio of natural aggregates replaced by regenerated bone (x 2 ), the ratio of recycled concrete aggregate to recycled aggregate (x 3 ), the vibration frequency of the mixed material (x 4 ), the vibration time of the mixed material (x 5 ), the recycled aggregate is a mixture of recycled concrete and recycled bricks, and the natural aggregate is small pieces of broken natural stone;

[0030] (2) According to the national standard, the particle size of the recycled aggregate (x 1 ) is divided into 6 levels, namely 4.75-9.5mm, 4.75-16mm, 4.75-19mm, 4.75-26.5mm, 4.75-31.5mm, 4.75-37.5mm, and other influencing factors of recycled aggregate particle size (x 1 ), the ratio of natural aggregates replaced by regenerated bone (x 2 ), the ratio of recycled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com