A foam automatic packaging device for LCD TV

An automatic packaging, LCD TV technology, applied in packaging and other directions, can solve the problems of poor work continuity, high labor cost, poor adjustability, etc., and achieve the effect of improving work efficiency and improving work continuity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

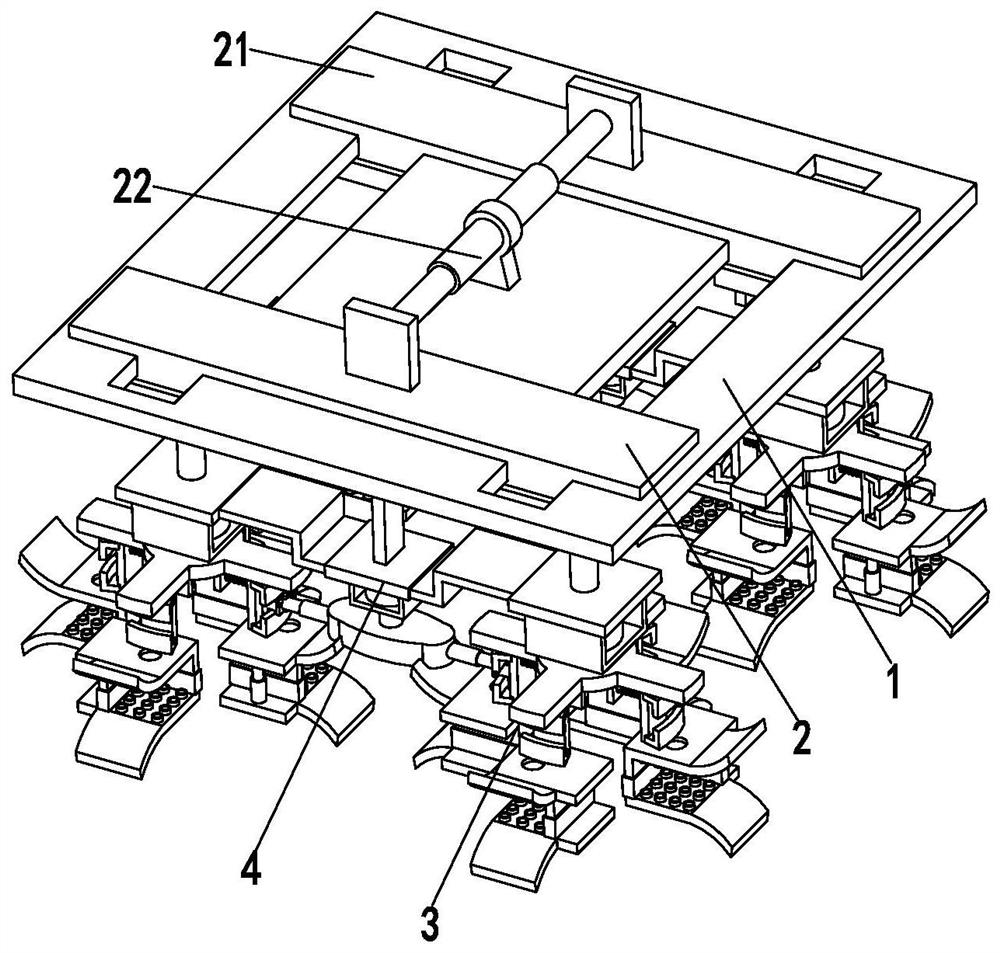

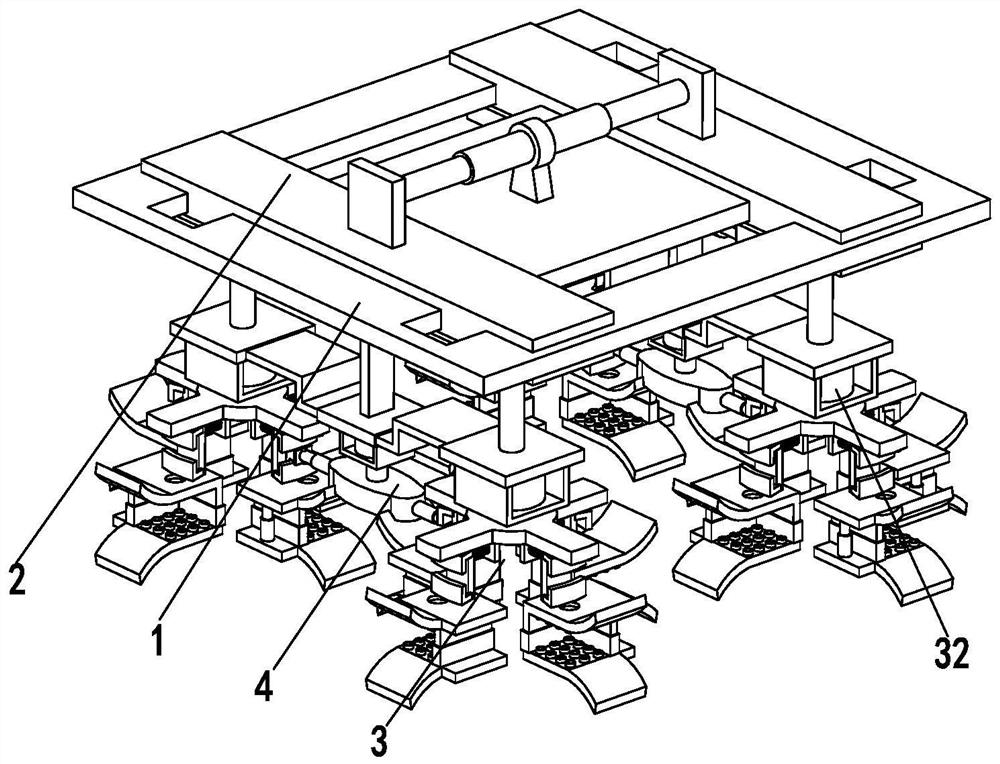

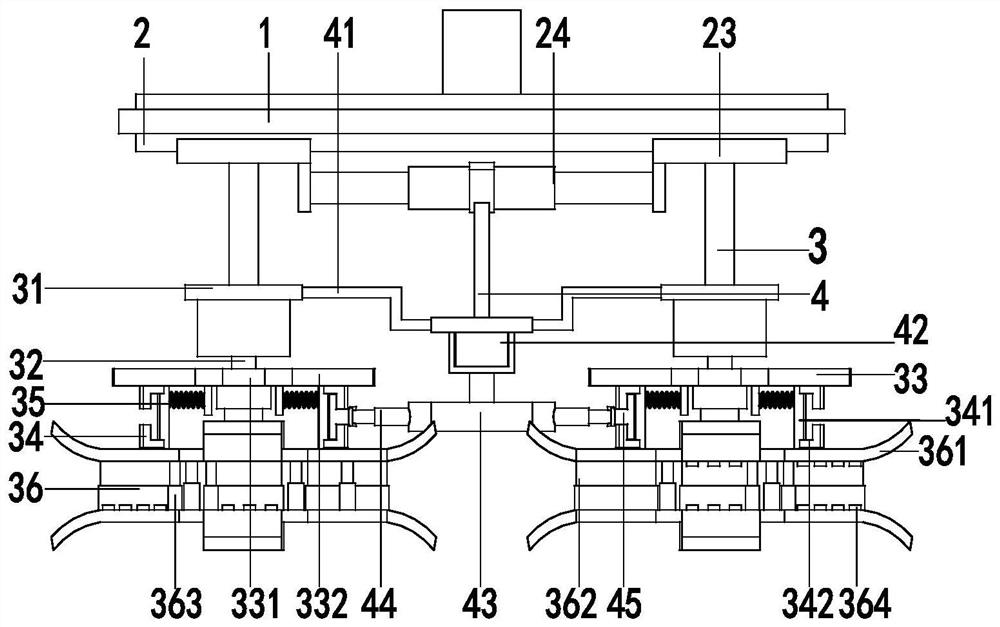

[0029] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the following is combined Figure 1 to Figure 3 , To further explain the present invention.

[0030] A foam automatic packaging device for LCD TVs, comprising a top plate 1, an adjusting mechanism 2, a conveying mechanism 3, and a packaging mechanism 4. The adjusting mechanism 2 is located between the top plate 1 and the conveying mechanism 3, and the side wall of the conveying mechanism 3 and the packaging Organization 4 is connected; among them:

[0031] The adjusting mechanism 2 includes an adjusting plate 21, an adjusting cylinder 22, a sliding block 23, and a working cylinder 24. The adjusting plate 21 is installed on the top plate 1 by sliding fit. The number of adjusting plates 21 is two, and the two adjusting plates 21 are arranged symmetrically. , An adjusting cylinder 22 is connected between the two adjusting plates 21, and the adjusting cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com