Automatic cutting device and method of tape of packing box

A technology for cutting devices and packaging boxes, which is applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of time-consuming and labor-intensive, large pollution risks, low manual operation efficiency, etc., achieve accurate and reliable operation, reduce manual labor intensity, The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

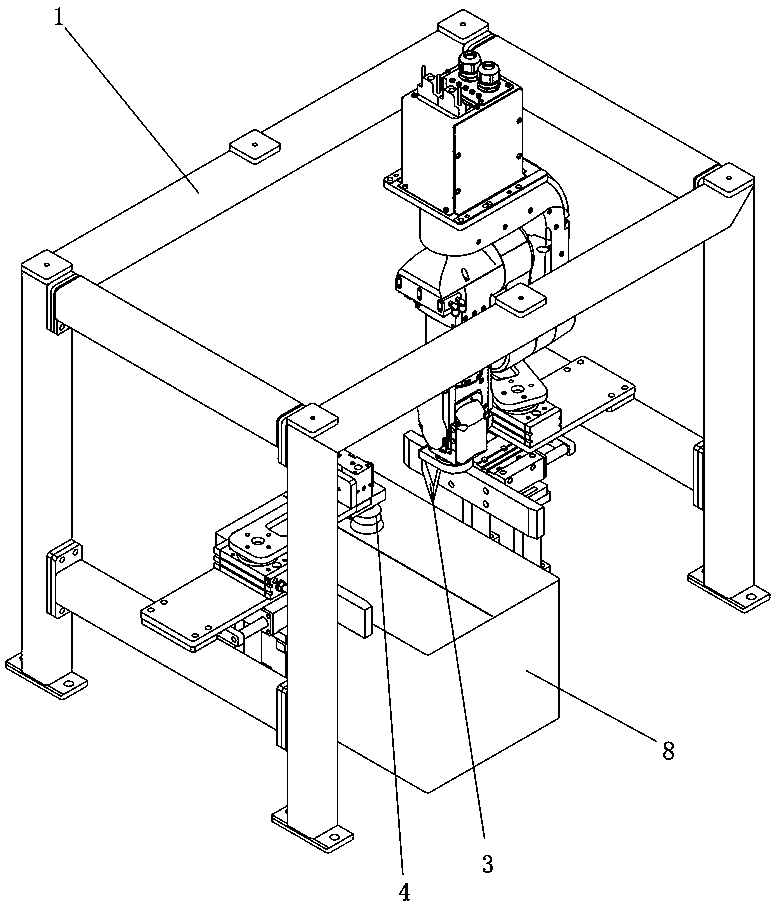

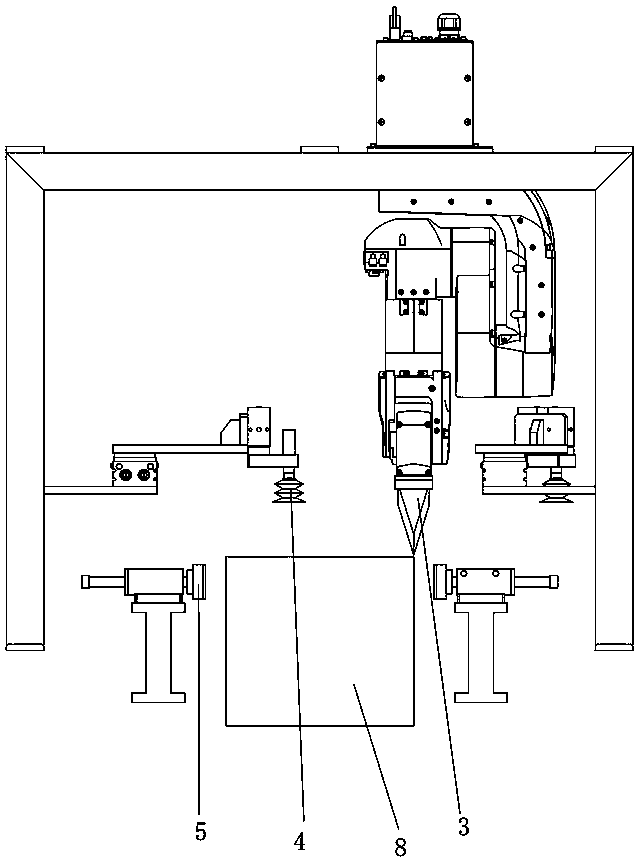

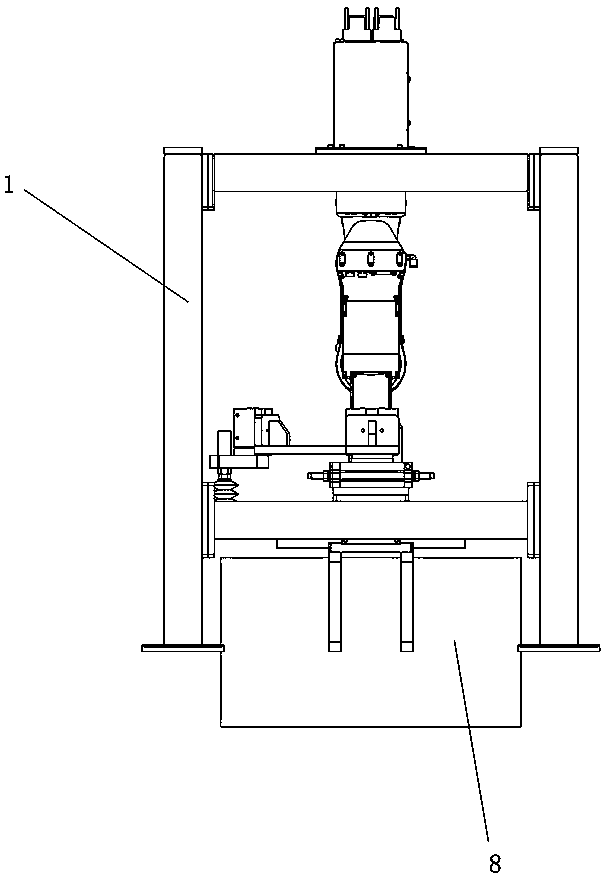

[0033] Figure 1 to Figure 7 It shows an embodiment of an automatic packing box tape cutting device, which includes a frame 1, a box conveying part 2, a cutter manipulator 3, a side positioning part 5 and two sets of suction cup assemblies 4 , the box conveyor part 2 is provided with a tape cutting station, the side positioning part 5 is located at the side of the tape cutting station to position the packing box 8, and the cutter manipulator 3 is installed on the frame 1 and is located at the tape cutting station The cutter 32 of the cutter manipulator 3 can turn over and move to cut the adhesive tape 9 on the outer hinge 81 of the packing box 8 and between the outer hinge 81 and the side plate 82, and the two groups of suction cup assemblies 4 are rotatably installed on the On the frame 1 and respectively located on both sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com