Battery PCM jointed board automatic blanking machine

An automatic punching machine and jigsaw technology, applied in metal processing, etc., can solve problems such as cumbersome operation, low efficiency, and low product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The embodiment of the present invention will be explained in detail below in conjunction with the accompanying drawings. The examples given are only for the purpose of illustration, and cannot be interpreted as limiting the present invention. The accompanying drawings are only for reference and description, and do not constitute the scope of patent protection of the present invention. limitations, since many changes may be made in the invention without departing from the spirit and scope of the invention.

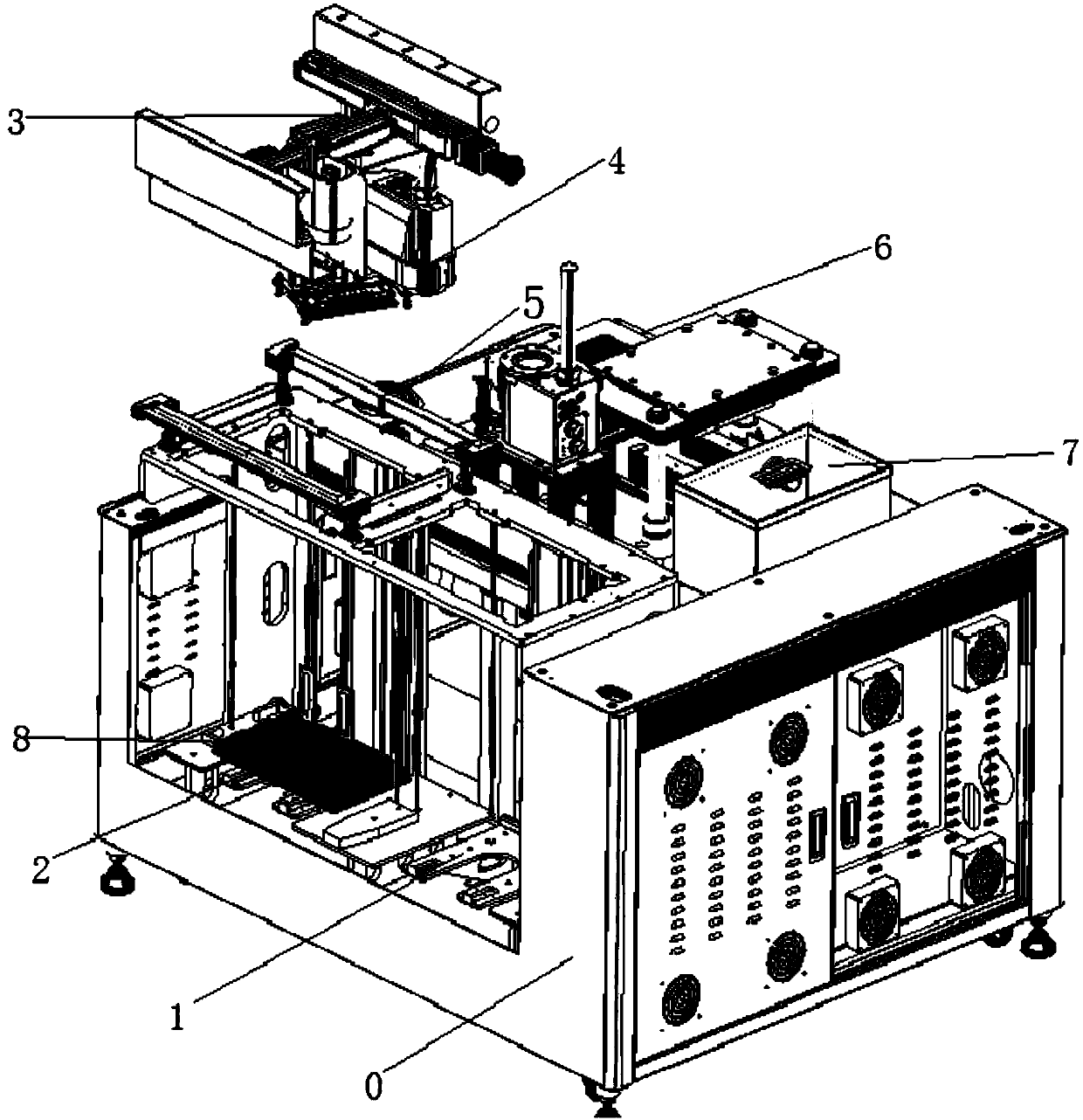

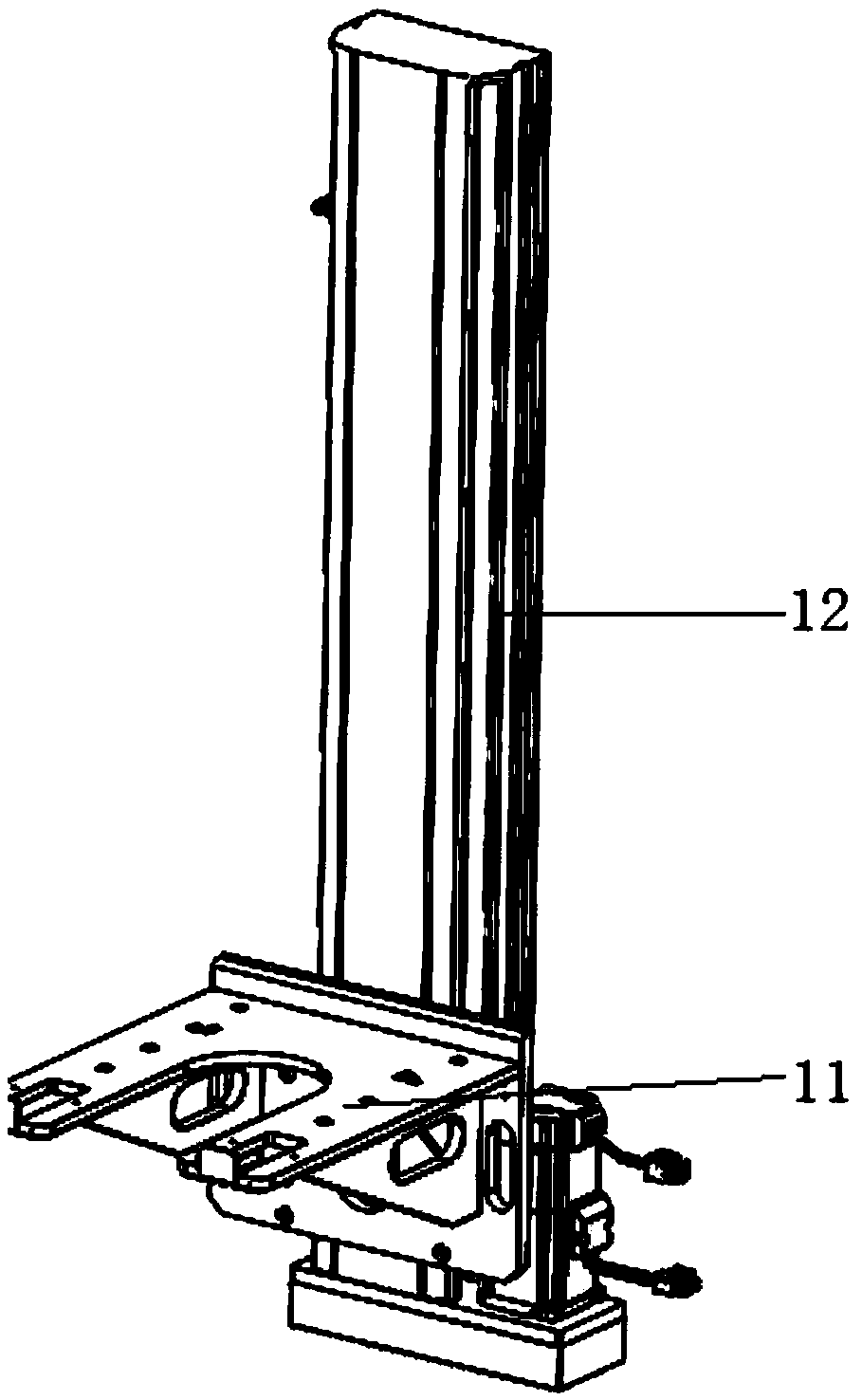

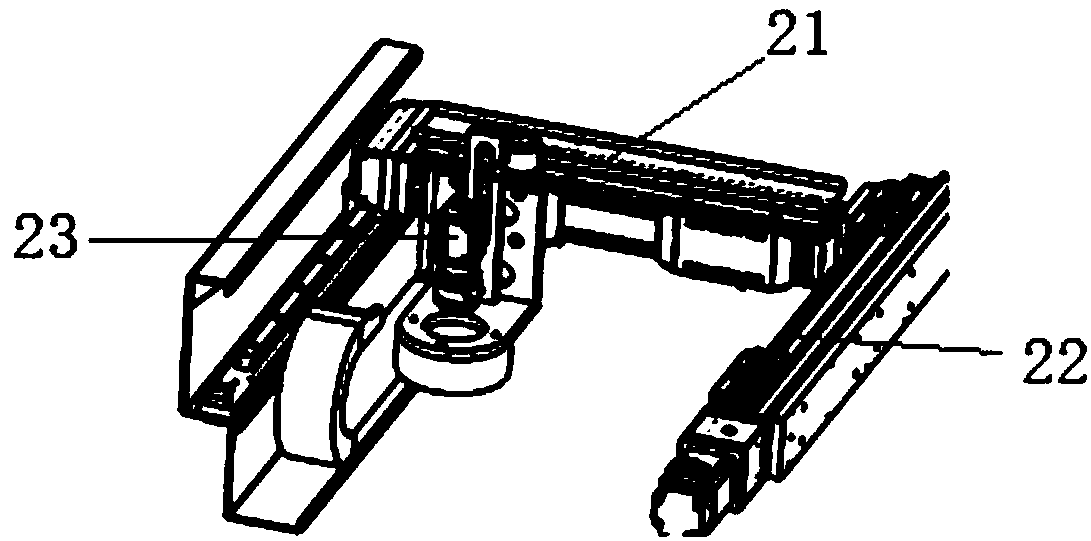

[0039] see figure 1 , an automatic punching machine for battery PCM panels provided by an embodiment of the present invention, including a blister box feeding mechanism and an empty blister box palletizing mechanism 3 arranged inside the cabinet 0, and a blister box stacking mechanism 3 arranged on the upper surface of the cabinet 0 The visual camera positioning mechanism for the jigsaw puzzle of the workbench 2, the four-axis manipulator feeding mechanism 4, the mar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com