A viscous medium pressure forming device for closed variable cross-section thin-walled parts

A technology for viscous medium and thin-walled parts, which is applied in the field of viscous medium pressure forming devices for closed variable-section thin-walled parts, which can solve problems such as inability to form integrally, local thinning, and cracking, so as to improve the uniformity of strain distribution and reduce wall thickness Poor, the effect of promoting deformation and flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

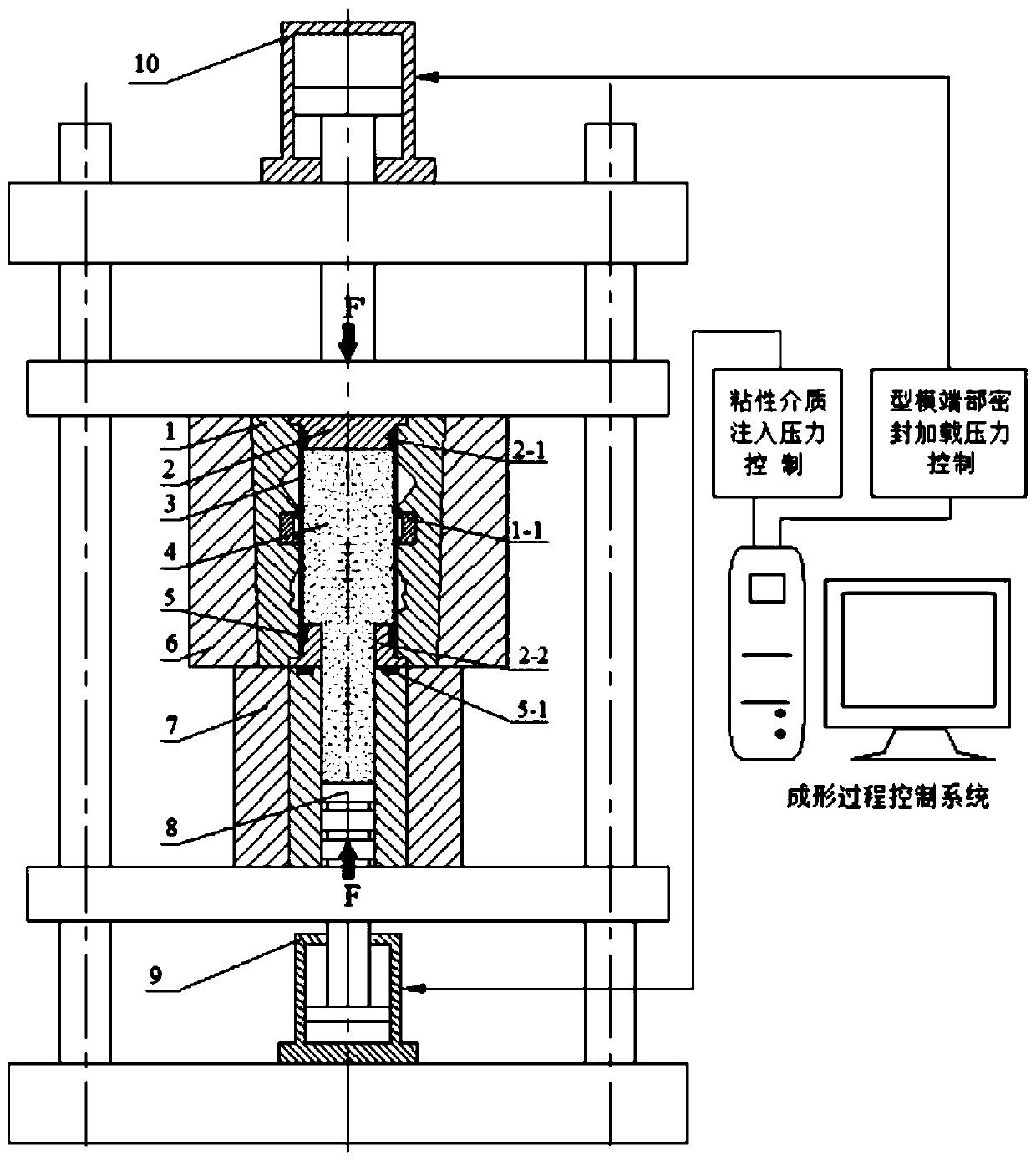

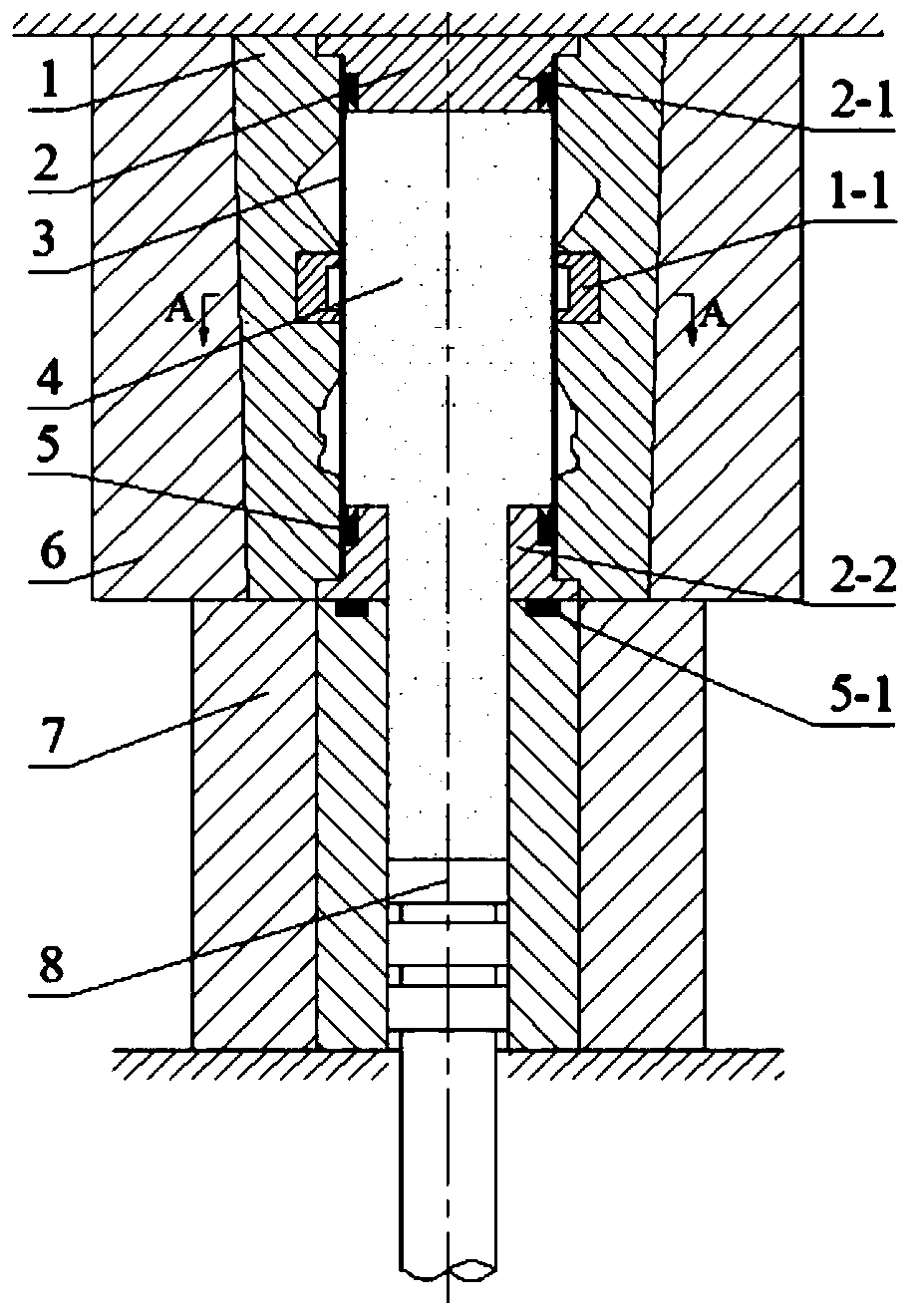

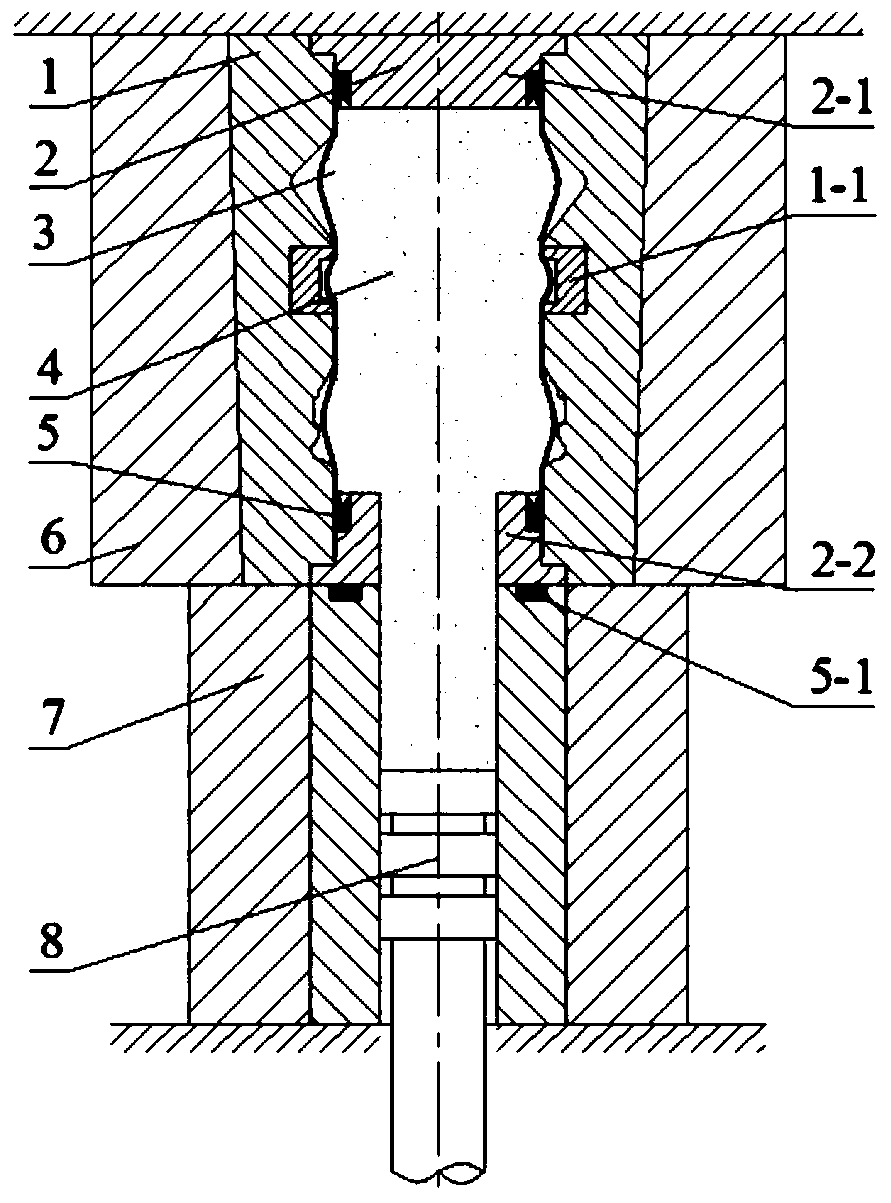

[0028] A viscous medium pressure forming device for closed variable-section thin-walled parts, see Figure 1-Figure 9 , The device includes a mold 1, a forming medium sealing ring 5, a mold sleeve 6, a viscous medium injection cylinder 7, a viscous medium loading power source hydraulic cylinder 9 and a mold end seal loading power source hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com