High-pressure washing robot device

A technology for cleaning robots and high-pressure water, which is applied to cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as shortened service life, inconvenient operation, and difficulty in accurate alignment, and achieve friction reduction and accurate positioning. counterpoint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

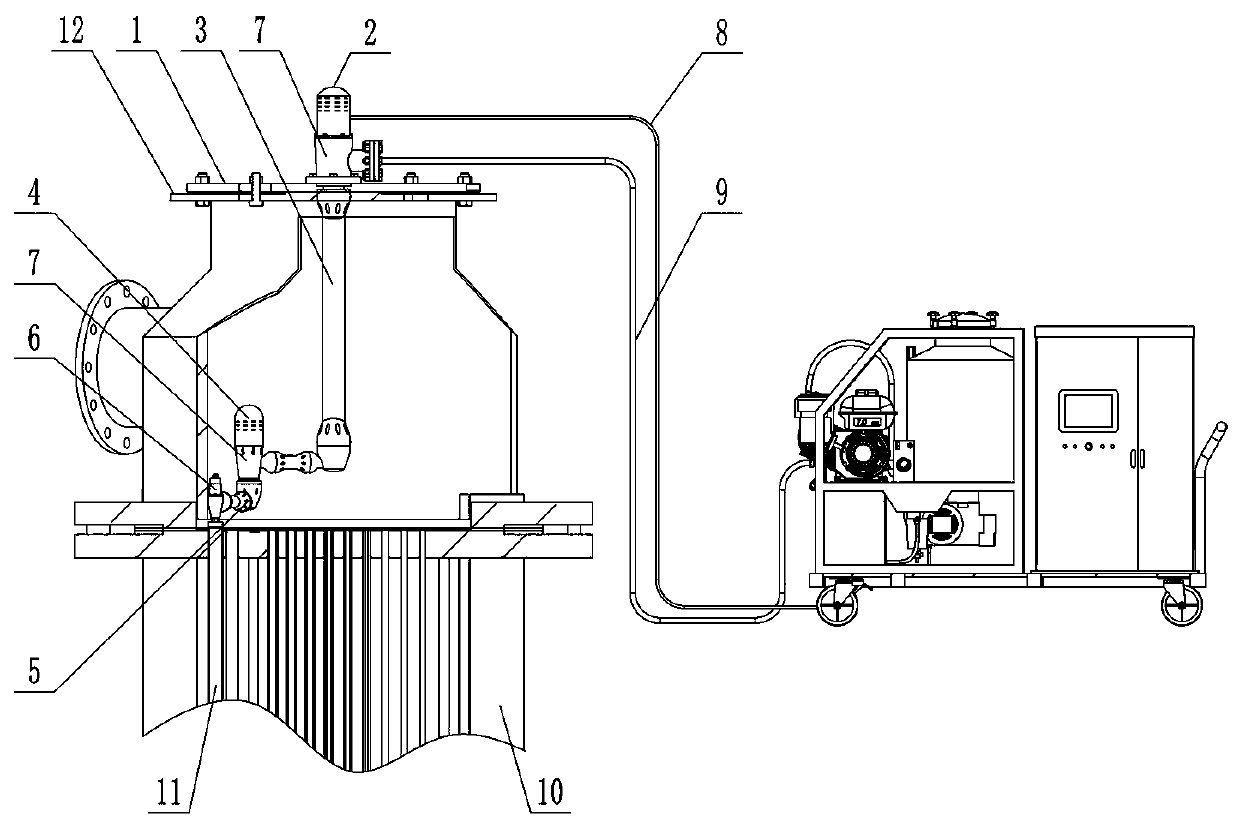

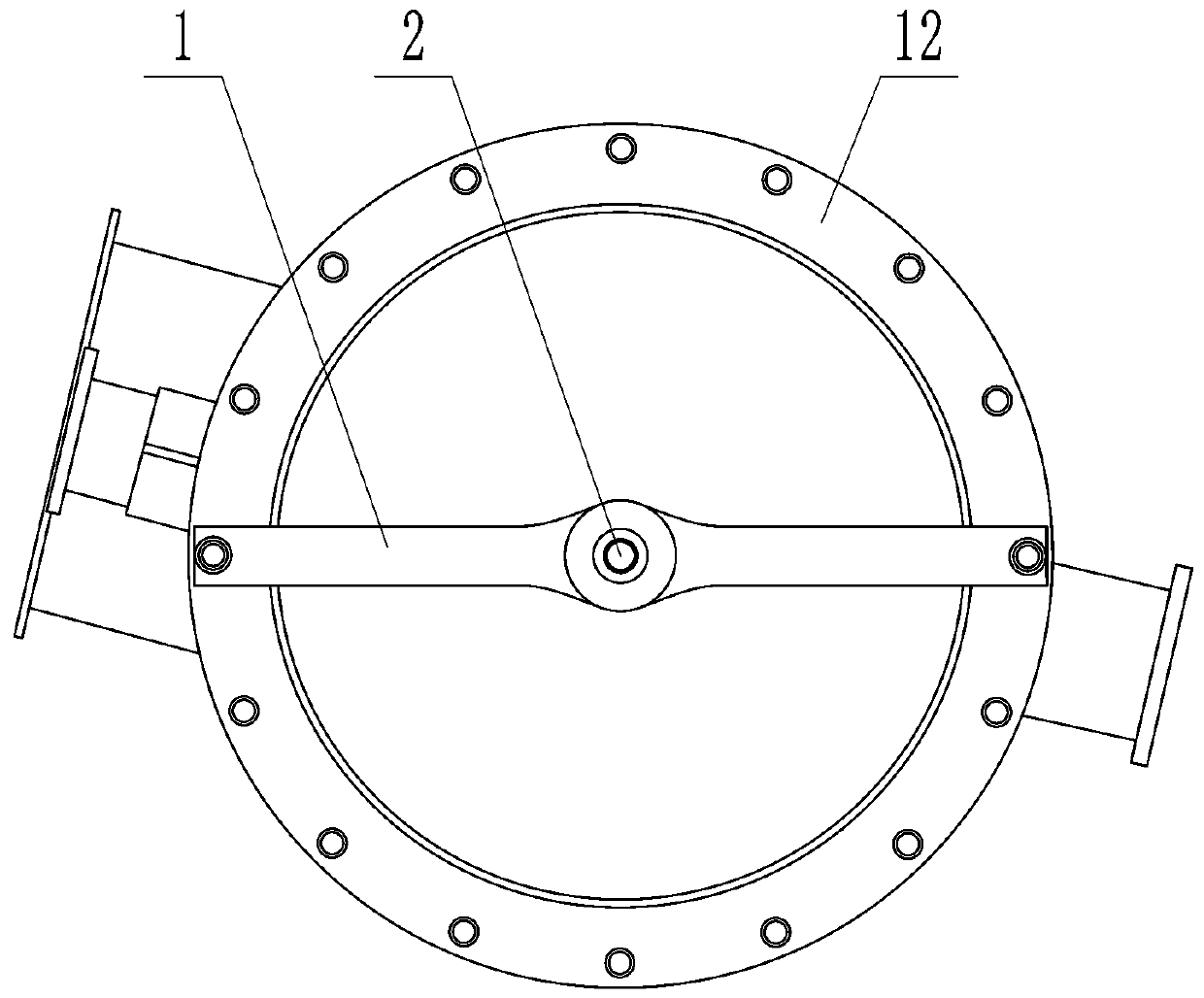

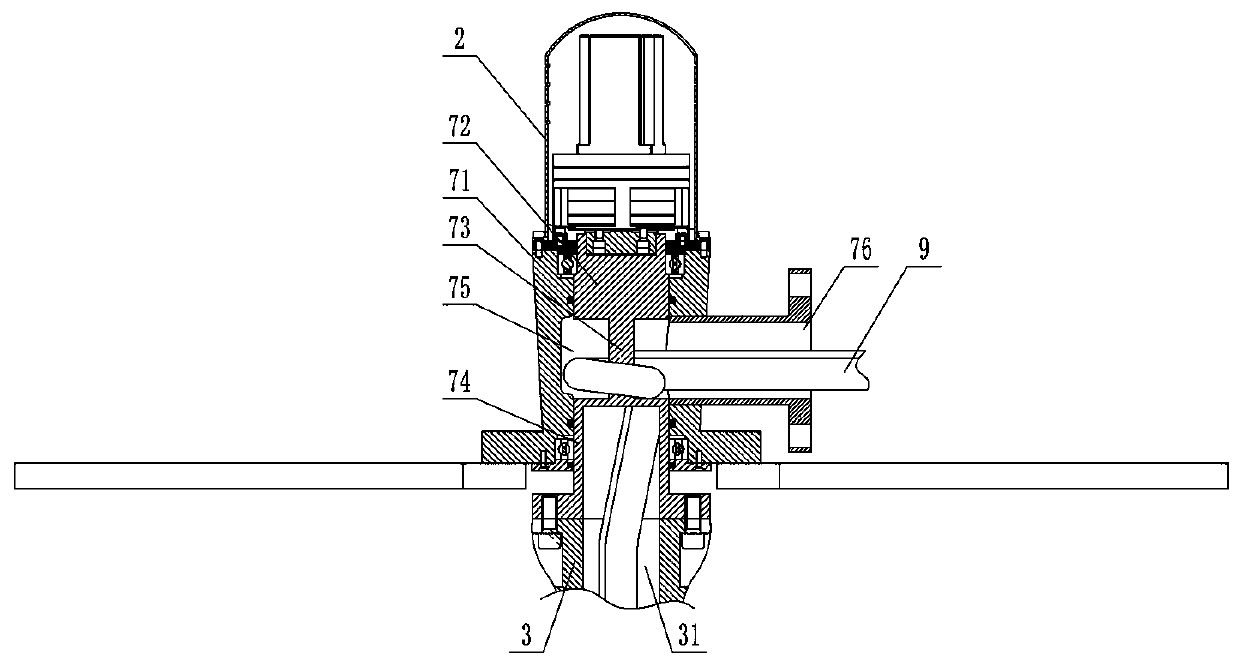

[0030] Such as Figure 1-4 As shown, a high-pressure water cleaning robot device includes a first driving motor 2, a first rotating mechanical arm 3, a second driving motor 4, a second rotating mechanical arm 5 and a spray mechanism 6; the first driving motor 2 passes through A rotary joint 7 drives the rotation of the first rotary mechanical arm 3, the second drive motor 4 is installed at the driving end of the first rotary mechanical arm 3, and the second drive motor 4 drives the second rotary mechanical arm 3 The arm 5 rotates, and the injection mechanism 6 is installed on the driving end of the second rotating mechanical arm 5; the first driving motor 2 and the first rotating mechanical arm 3 form a primary driving mechanism, and the second driving motor 4 and the second rotating mechanical arm The mechanical arm 5 forms a secondary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com