A Soil Column Prototyping Machine

A technology for making prototypes and soil columns, applied in the field of geotechnical testing, can solve problems such as hindering in-depth research and engineering application of soil column physical mechanics, restricting stable acquisition of soil column related parameters, and increasing operating procedures, so as to achieve uniform force and smoothness. The effect of consistency and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific implementation manners described here are only used to illustrate and explain the embodiments of the present invention, and are not intended to limit the embodiments of the present invention.

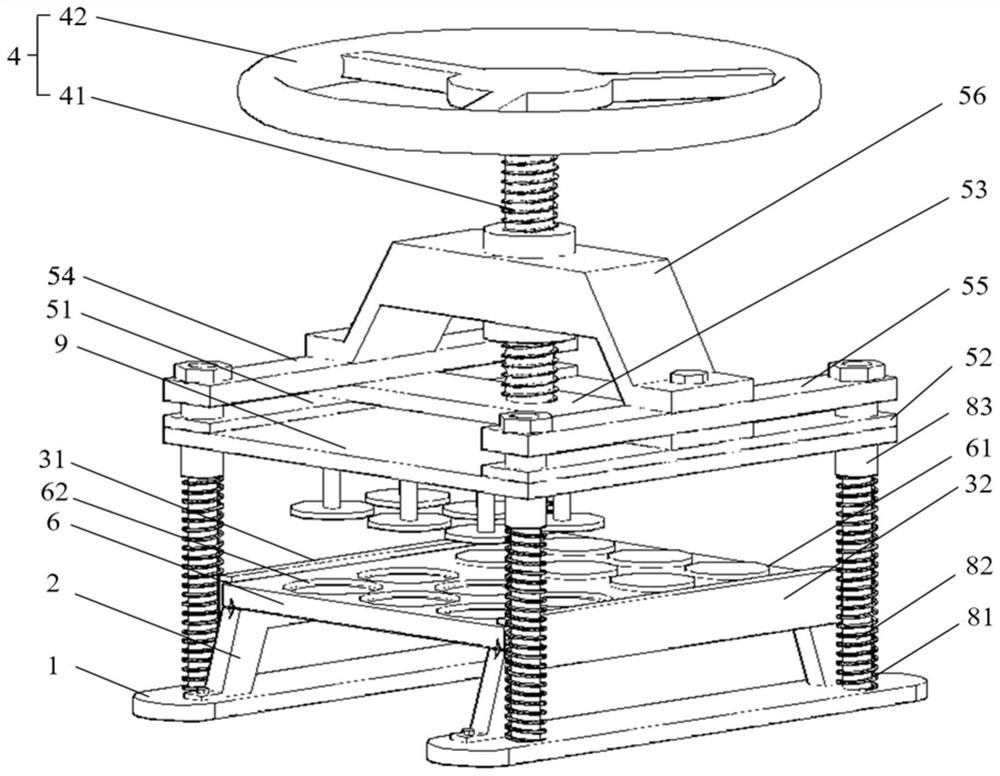

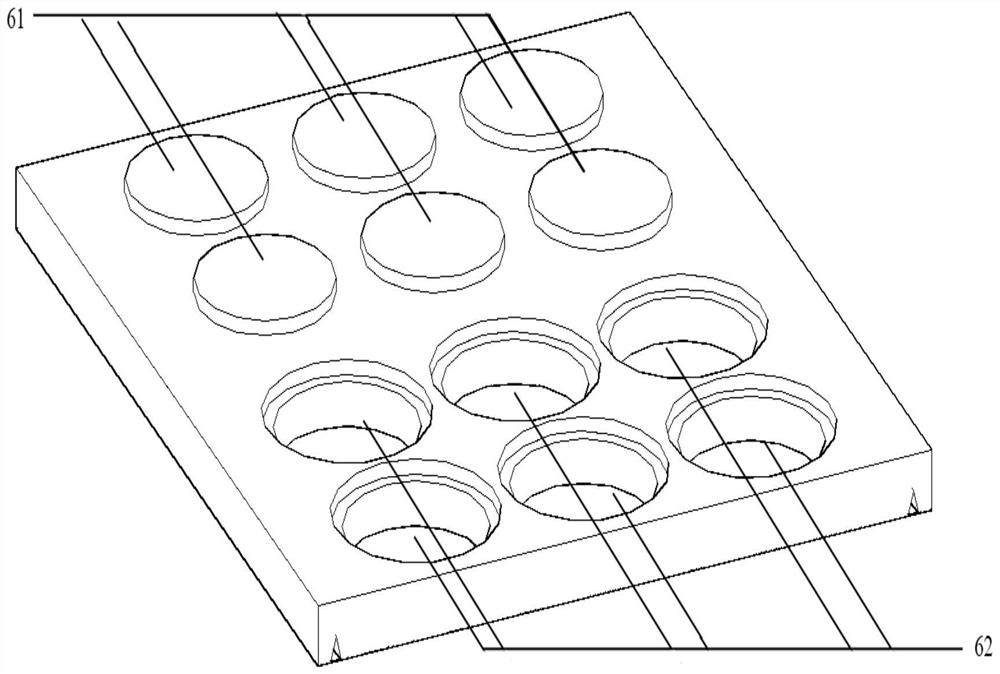

[0028] see Figure 1-Figure 9, the present invention provides a technical solution: a soil column sample making machine, including a base 1, a base frame 2, a limit assembly 3, a drive assembly 4, a support bracket 5, a stamping plate 9, a mold plate 6, a spring 81, and a sample preparation cylinder 71 and spacer 72, the upper end of the base 1 is welded with the base platform 2, the upper end of the support bracket 5 supports the driving assembly 4, the driving assembly 4 drives the stamping plate 9 to slide vertically, and the mold plate 6 slides horizontally between the base pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com