Soybean airing frame

A drying rack and soybean technology, applied in the field of drying racks, can solve the problems of poor drying effect, poor ventilation of soybean rods, low efficiency, etc., and achieve the effects of convenient ventilation and drying, easy maintenance and repair, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

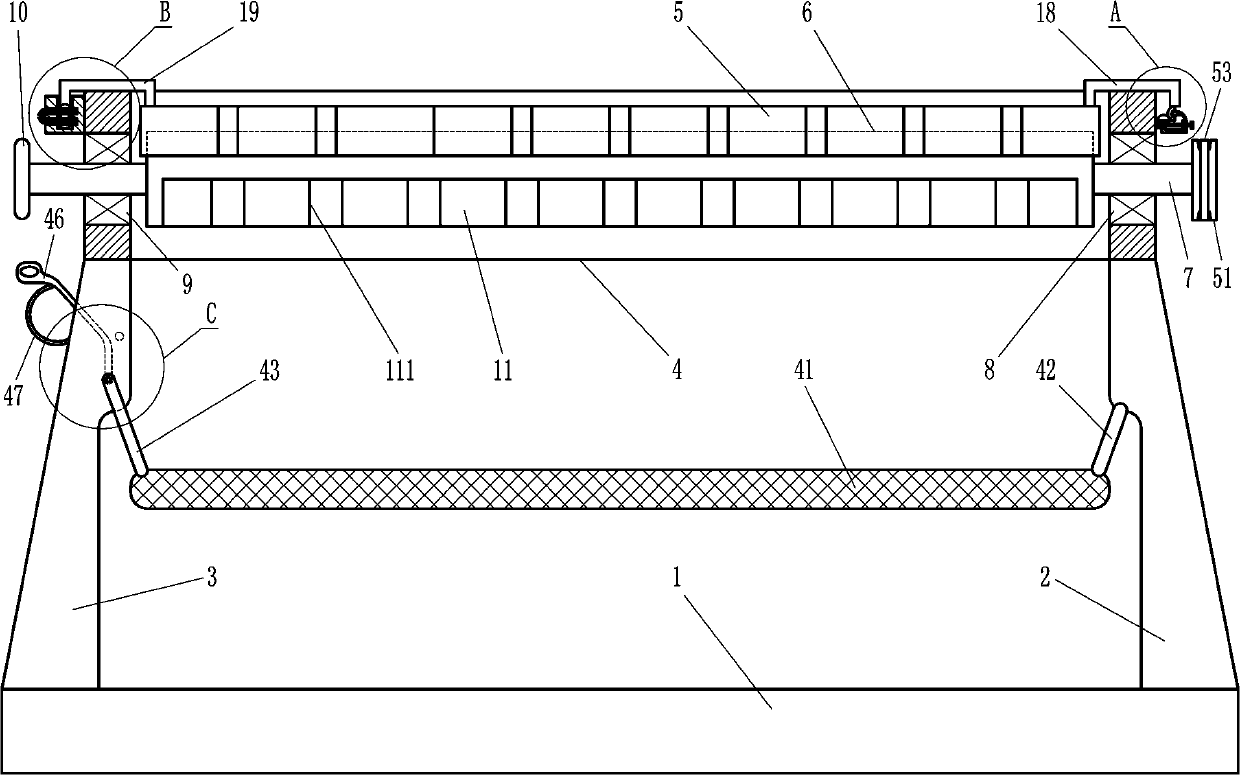

[0020] A drying rack for soybeans such as Figure 1-6 As shown, it includes a base 1, a right bracket 2, a left bracket 3, a rectangular frame plate 4, a grid plate 5, a first rotating roller shaft 6, a first rotating shaft 7, a first bearing 8, a second bearing 9, a first A rotating wheel 10, a first arc-shaped push block 11, a second rotating roller shaft 12, a second rotating shaft 13, a third bearing 14, a fourth bearing 15, a second rotating wheel 16, a second arc-shaped push block 17, First inverted concave plate 18, second inverted concave plate 19, semi-annular plate 20, circular chuck 21, small triangular block 22, arc elastic pressure piece 23, concave movable plate 24, semicircular block 25. Small guide rod 26, small spring 27, small insert plate 28, small box body 29, U-shaped insert rod 30, first small arc-shaped leaf spring 31, first right-angle block 32, second small arc-shaped leaf spring 33 and the second rectangular block 34, the right end of base 1 top is c...

Embodiment 2

[0022] A drying rack for soybeans such as Figure 1-6 As shown, it includes a base 1, a right bracket 2, a left bracket 3, a rectangular frame plate 4, a grid plate 5, a first rotating roller shaft 6, a first rotating shaft 7, a first bearing 8, a second bearing 9, a first A rotating wheel 10, a first arc-shaped push block 11, a second rotating roller shaft 12, a second rotating shaft 13, a third bearing 14, a fourth bearing 15, a second rotating wheel 16, a second arc-shaped push block 17, First inverted concave plate 18, second inverted concave plate 19, semi-annular plate 20, circular chuck 21, small triangular block 22, arc elastic pressure piece 23, concave movable plate 24, semicircular block 25. Small guide rod 26, small spring 27, small insert plate 28, small box body 29, U-shaped insert rod 30, first small arc-shaped leaf spring 31, first right-angle block 32, second small arc-shaped leaf spring 33 and the second rectangular block 34, the right end of base 1 top is c...

Embodiment 3

[0025] A drying rack for soybeans such as Figure 1-6 As shown, it includes a base 1, a right bracket 2, a left bracket 3, a rectangular frame plate 4, a grid plate 5, a first rotating roller shaft 6, a first rotating shaft 7, a first bearing 8, a second bearing 9, a first A rotating wheel 10, a first arc-shaped push block 11, a second rotating roller shaft 12, a second rotating shaft 13, a third bearing 14, a fourth bearing 15, a second rotating wheel 16, a second arc-shaped push block 17, First inverted concave plate 18, second inverted concave plate 19, semi-annular plate 20, circular chuck 21, small triangular block 22, arc elastic pressure piece 23, concave movable plate 24, semicircular block 25. Small guide rod 26, small spring 27, small insert plate 28, small box body 29, U-shaped insert rod 30, first small arc-shaped leaf spring 31, first right-angle block 32, second small arc-shaped leaf spring 33 and the second rectangular block 34, the right end of base 1 top is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com