Template table with integrated installation of beam columns

A technology for installing boards and templates, which is applied in the field preparation of formwork/formwork/work frames, building components, construction, etc., which can solve the problems of troublesome disassembly, cumbersome installation, and poor practicability, and achieve low installation requirements. Large adjustment range and good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

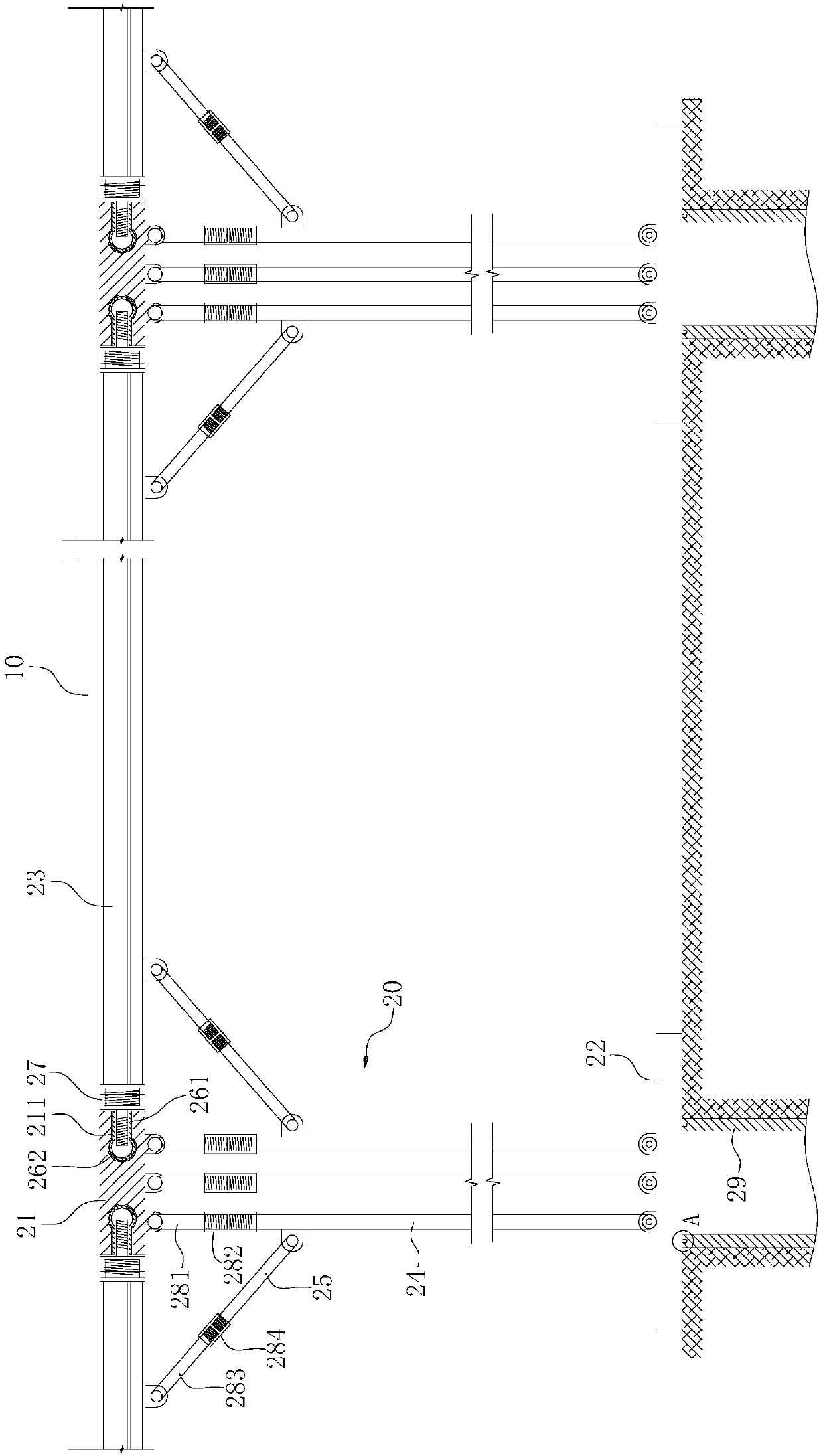

[0022] see Figure 1 to Figure 3 .

[0023] The formwork platform for the integrated installation of beams and columns in the present invention includes a formwork 10 and more than two pairs of integrated beams and columns 20 installed at the bottom of the formwork 10; the integrated beams and columns 20 include a support plate 21, a mounting plate 22, Two or more cross brace beams 23, vertical braces 24 with the same number as the two or more cross brace beams 23, and diagonal braces 25 with the same number as the two or more cross brace beams 23;

[0024] The support plate 21 is circular, the outer peripheral wall of the support plate 21 is provided with an annular guide rail groove 211 extending...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com