Structure capable of adjusting area of outlet of spraying nozzle

A nozzle outlet, adjustable technology, applied in the direction of injection devices, injection devices, etc., can solve the problems of small nozzles that are difficult to apply, complex methods and structures, etc., and achieve the effects of simple structure, small vibration and swing, and reduced resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will now be further described with reference to the drawings and specific embodiments.

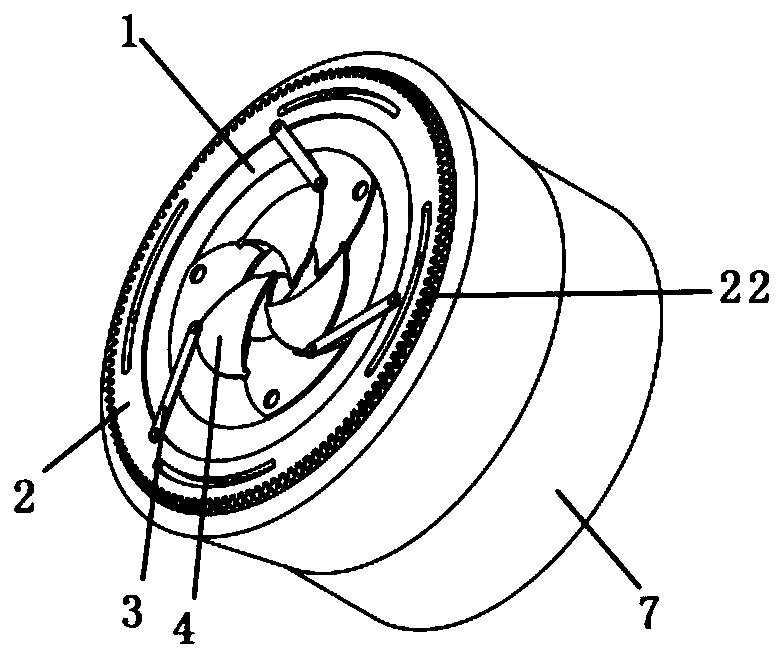

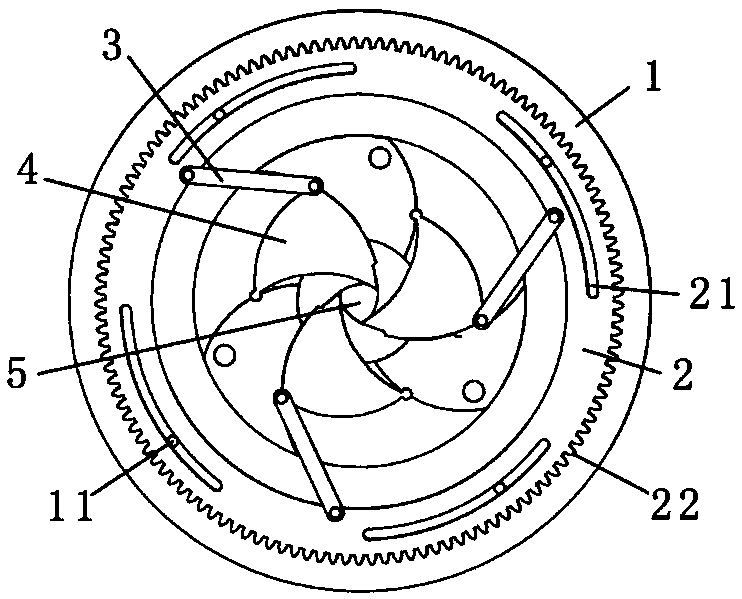

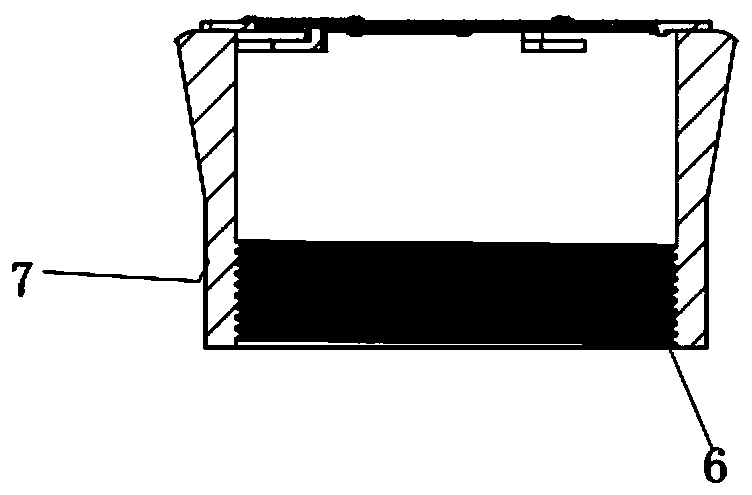

[0023] Such as Figure 1-5 As shown, a structure that can adjust the nozzle outlet area includes a top cover 7, a chassis 1, a turntable 2, a connecting rod 3, and a shutter 4. The top cover 7 is a cylindrical structure with front and rear openings. The rear end of the cover 7 is used to be fixed on the outlet end of the nozzle. In this specific implementation, the top cover 7 is preferably a cylindrical structure with a front and rear opening. The rear end of the top cover 7 is provided with an internal thread 6 for communication with The external thread of the nozzle outlet end is screwed and fixed. With this threaded connection structure, there is no need to make too many changes to the nozzle. It is only necessary to machine the outer wall of the nozzle outlet end with external threads, and it is easy to install and disassemble. Of course, in other embodiments...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com