A rectifier dust collector

A dust collector and support plate technology, applied in chemical instruments and methods, electrode cleaning, electrostatic effect separation, etc., can solve problems such as troublesome operation, damage to the dust removal roller, and failure to replace the dust removal roller, so as to save waste and avoid replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

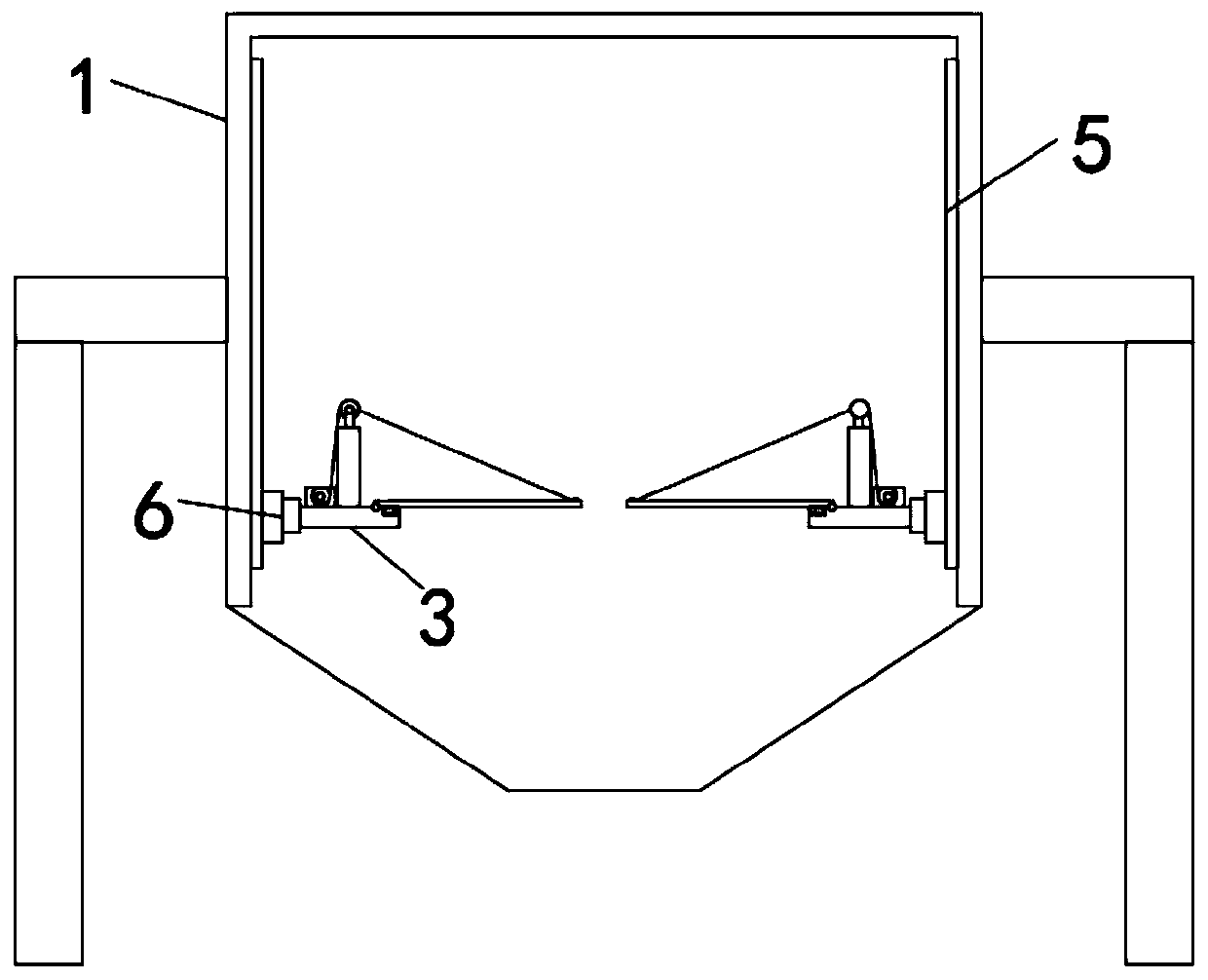

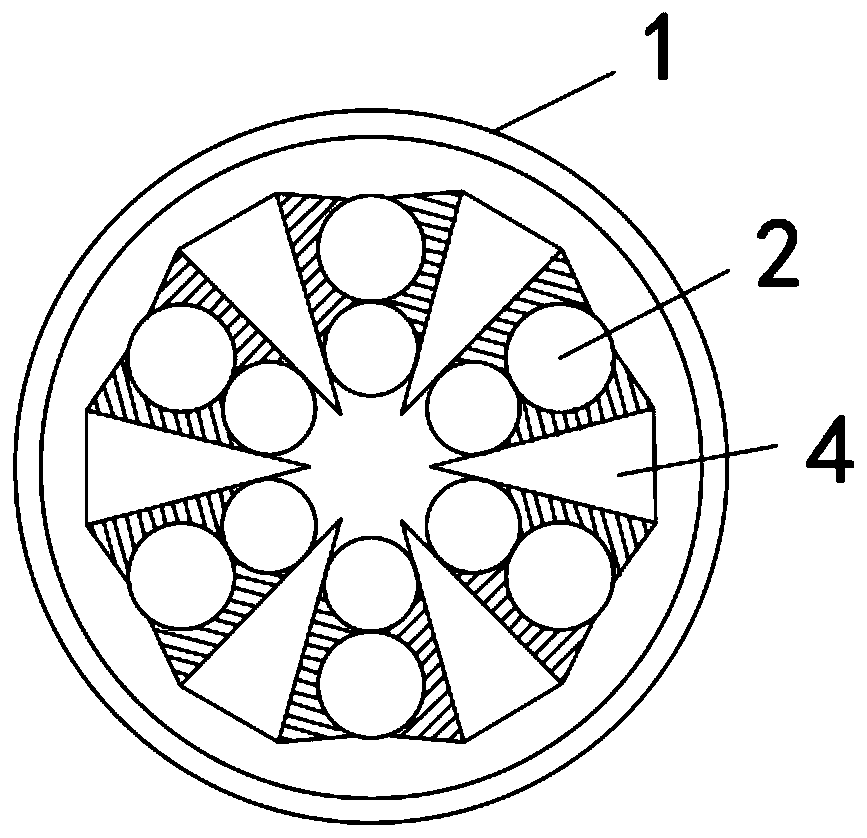

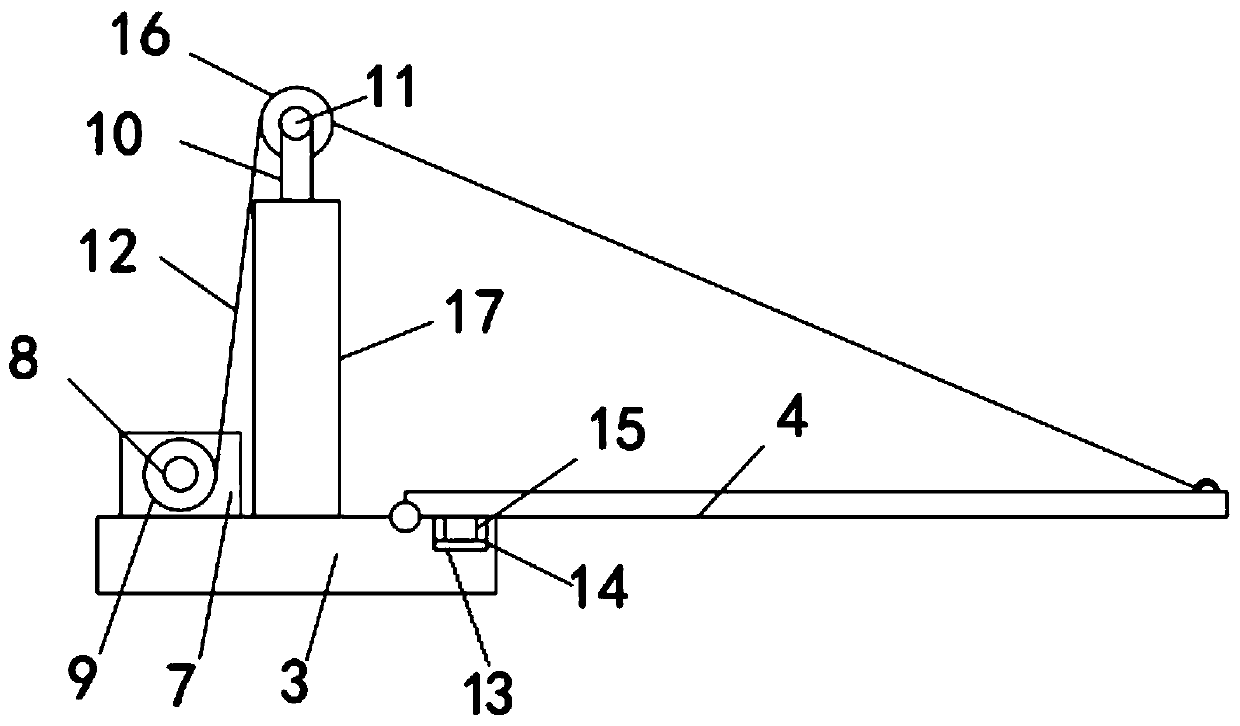

[0022] refer to Figure 1-3 , a rectifier dust collector, including dust collector 1, wherein the rectifier dust collector is a new type of dust collector that relies on different voltages to prevent safety, and can ensure the safety of the machine when the dust collector encounters voltage danger. It is the prior art, so it will not be stated too much here. The inner top of the dust remover 1 is fixedly connected with multiple dust removal rollers 2, and the side wall of the dust remover 1 is fixedly connected with a plurality of moving mechanisms. The electric slide rail 5 on the inner side wall is provided with an electric slider 6 on the side wall of the electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com