A process for rapid freezing using liquid nitrogen

A liquid nitrogen and process technology, applied in the application, food freezing, preservation of meat/fish by freezing/cooling, etc., can solve the problems of increasing freezing costs, increasing the number of equipment, increasing the requirements of freezing equipment, etc., to reduce freezing costs, adapt to Sexual expansion, efficiency and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

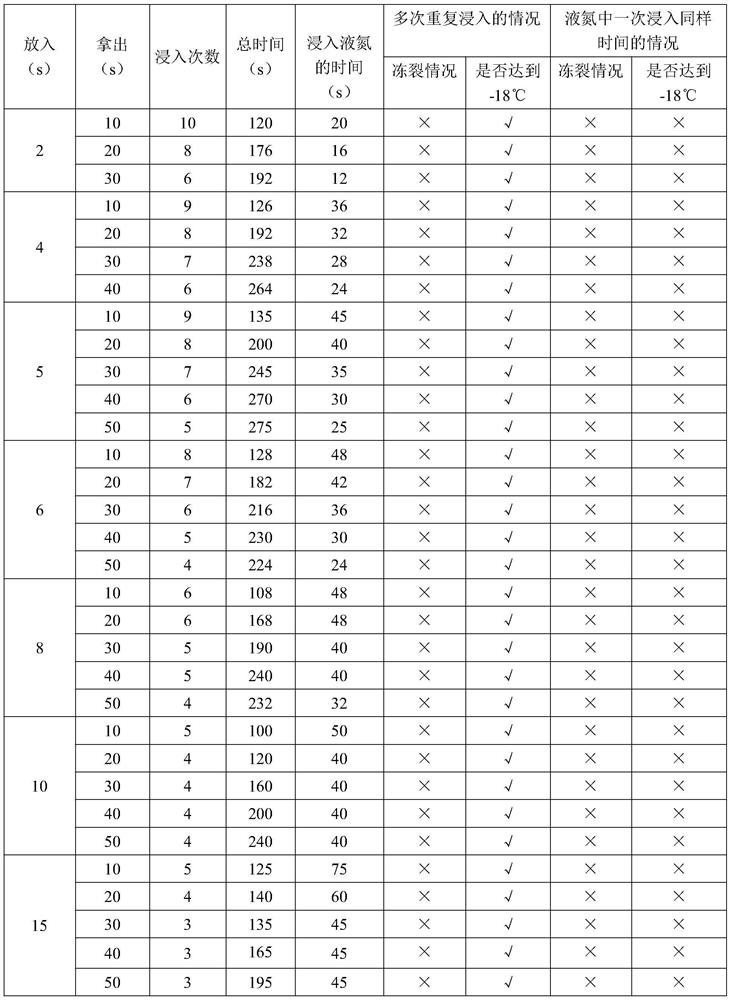

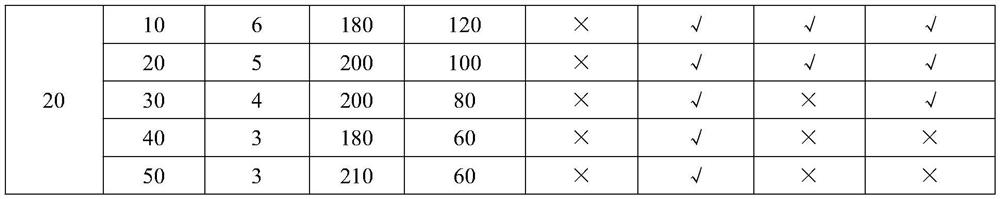

[0034] The technical scheme of the present invention is described below with specific examples, but protection scope of the present invention is not limited thereto:

[0035] 1. Experimental materials: Dumplings stuffed with leek and egg are used as the material, and the weight is 20g / piece.

[0036] experimental method:

[0037] 1. Put the dumplings in the refrigerator at 4°C for 20 minutes, take them out, measure the center temperature, and record.

[0038] 2. Put the dumplings into a liquid nitrogen tank filled with liquid nitrogen at -196°C, and quickly freeze them according to the different freezing times in the table below. The infrared thermometer records the temperature of the center of the dumpling, and observes the freezing and cracking of the surface of the dumpling.

[0039] Experimental results:

[0040]

[0041] 2. Experimental material: glutinous rice balls

[0042] Making of glutinous rice balls

[0043] Filling: 180g quick-frozen oil, 240g granulated s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com