Lead battery plate lead paste formula for electric road vehicle

A technology for road vehicles and lead-acid batteries. It is applied in the direction of lead-acid battery electrodes, battery electrodes, circuits, etc. It can solve the problems of excessive self-discharge, poor charging acceptance, unstable environment and pollution sources, etc., and achieve small self-discharge electrodes, The effect of strong charging acceptance and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below, so as to make the technical solution of the present invention easier to understand and grasp.

[0026] A lead-acid battery raw plate lead paste formula for electric road vehicles, comprising a positive lead paste formula and a negative lead paste formula, characterized in that the positive lead paste formula is composed of the following raw materials by weight percentage:

[0027]

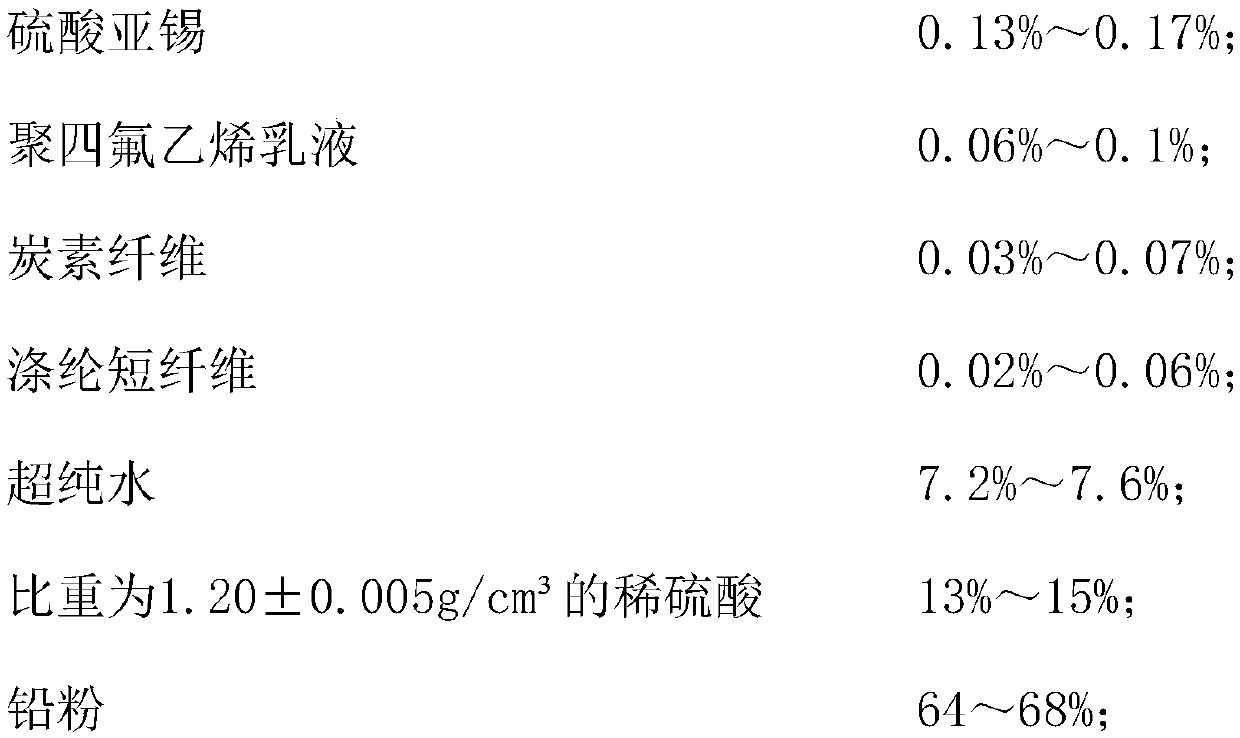

[0028] Described negative plate lead paste formula is made up of following raw material by weight percentage:

[0029]

[0030]

[0031] The density of the positive lead paste in the present invention is 4.16~4.26g / cm 3 , the density of negative lead paste is 4.26~4.36g / cm 3 .

[0032] Technical effect of the present invention is mainly reflected in:

[0033] (1) The internal resistance of the battery produced by this formula is extremely small, and the internal resistance of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com