Turbine rotor transient stress detection method

A steam turbine rotor and transient stress technology, applied in the steam turbine field, can solve the problems of low result accuracy, low calculation efficiency, cumbersome and time-consuming modeling process, etc., and achieve the effect of improving prediction ability and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The principles and features of the present invention will be described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

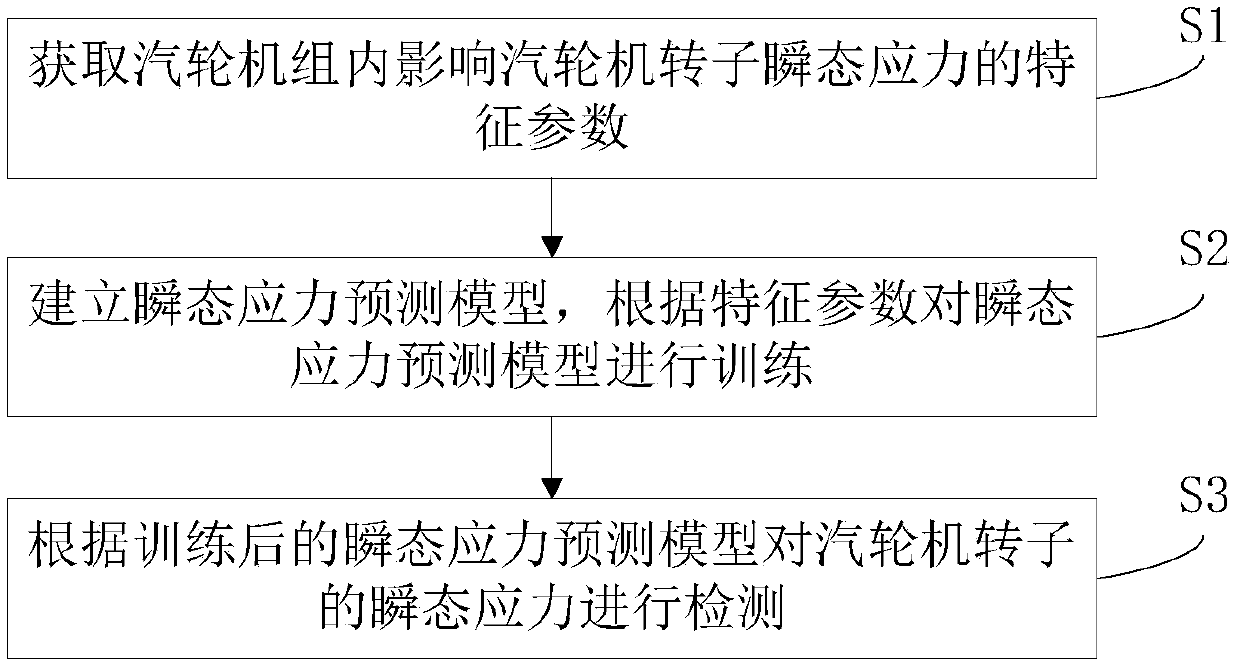

[0018] like figure 1 As shown, the flow diagram provided for the embodiment of the detection method of the transient stress of the steam turbine rotor of the present invention, the detection method includes:

[0019] S1, to obtain the characteristic parameters affecting the transient stress of the steam turbine rotor in the steam turbine unit.

[0020] It should be noted that since there are many characteristic parameters involved in the steam turbine unit, the correlation between different characteristics and rotor stress is different. If the characteristics with low correlation are added to the model, it is equivalent to adding noise to the model, which will not only reduce the Accuracy will also increase the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com