Device for rapid assessment of cook-off response degree of solid propellant

A solid propellant and high-level technology, which is applied in the direction of chemical analysis by means of combustion, can solve the problems of high cost, complicated tooling, and large amount of charge, and achieve the effect of low cost, large amount of charge, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

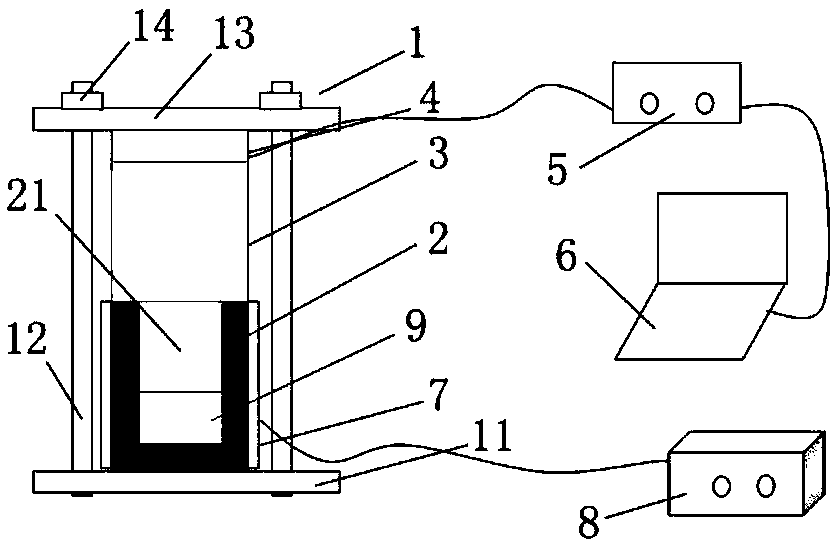

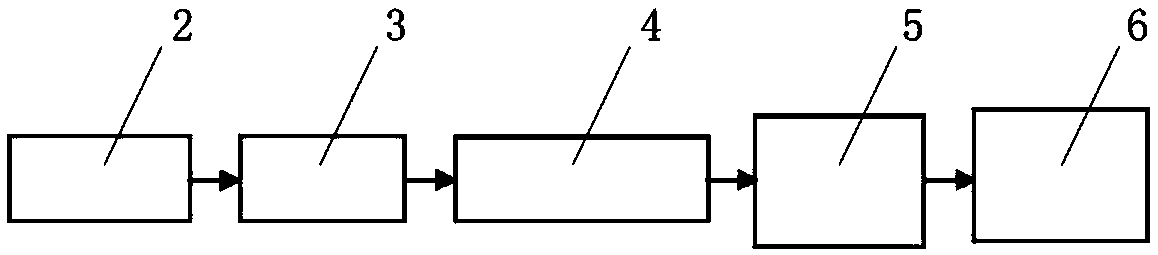

[0019] see figure 1 , a device for quickly evaluating the cook-off response of solid propellants, comprising a fixed frame 1, an explosion chamber 2 is provided at the bottom of the fixed frame, and a sample groove 21 is provided in the middle of the explosion chamber, and the sample groove The mouth is sealed by the top column 3, the top column is provided with a pressure sensor 4, the pressure sensor is connected to the signal conditioner 5, the signal conditioner is connected to the data collector 6, and the outside of the explosion chamber is wrapped and heated Cover 7, the heating jacket is connected with temperature program controller 8.

[0020] In this embodiment, the explosion chamber 2 consists of 45 # Machined from steel, the top column 3 is made of 45 # Steel is machined.

[0021] In this embodiment, a temperature sensor is provided between the explosion chamber and the heating jacket, and the temperature sensor is connected to the temperature program controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com