Structure and method for preventing start failure of overhead standby pump

A backup pump and top-mounted technology, which is applied in the field of lubrication systems, can solve the problems of enlarged overall volume and installation space, damage to host equipment, pressure and flow reduction, etc., to avoid production efficiency reduction, prevent startup failure, and facilitate use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

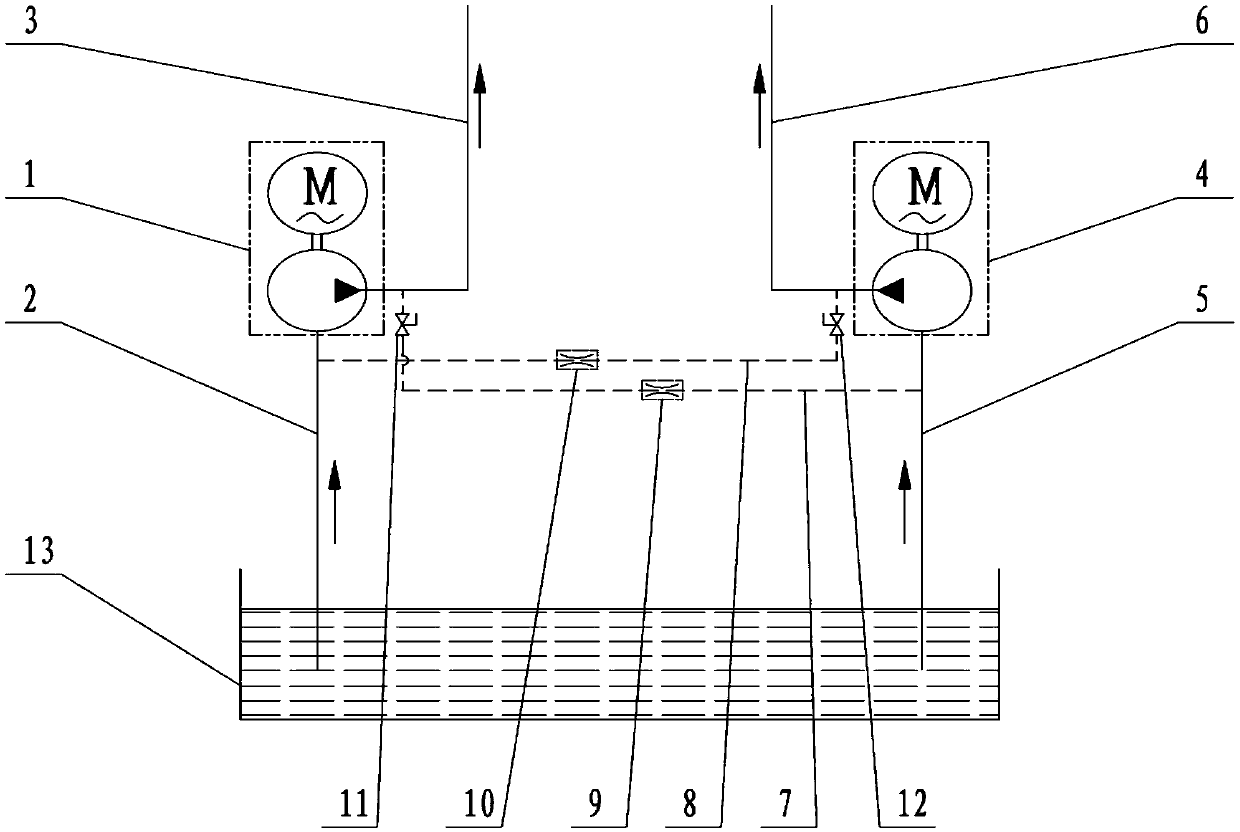

[0019] Such as figure 1 As shown, in this embodiment, a structure and method for preventing overhead standby pump from starting failure includes a fuel tank 13, a main oil pump 1 communicated with the fuel tank 13 through the main oil suction pipe 2, and a pump 1 communicated with the fuel tank 13 through the auxiliary oil suction pipe 5. The auxiliary oil pump 4, the main oil pump 1 is connected with the main oil outlet pipe 3 for outputting oil, the auxiliary oil pump 4 is connected with the auxiliary oil outlet pipe 6 for outputting oil, and the main oil outlet pipe 3 and the auxiliary oil suction pipe 5 are connected with a main Oil guide pipe 7.

[0020] When working, start the main oil pump 1 and close the auxiliary oil pump 4, so that the main oil pump 1 is connected to the equipment that needs to be lubricated through the main oil outlet pipe 3 to facilitate the delivery of lubricating oil. During the delivery process, part of the oil pumped by the main oil pump 1 pass...

Embodiment 2

[0024] On the basis of the above-mentioned embodiments, in this embodiment, an auxiliary oil introduction pipe 8 communicates between the auxiliary oil outlet pipe 6 and the main oil suction pipe 2 . After the main oil pump 1 is shut down and the auxiliary oil pump 4 is started, the main oil pump 1 in the stopped state can be overhauled to eliminate the fault. At this time, after the main oil pump 1 is connected to the oil tank 13, there will also be in the main oil suction pipe 2 and the main oil pump 1 Air. When the auxiliary oil pump 4 wants to pump lubricating oil, the auxiliary oil pipe 8 can be used to pump lubricating oil into the main oil suction pipe 2 at the same time, so as to discharge the air in the main oil suction pipe 2 and the main oil pump 1, so as to avoid using the main oil pump next time. The oil pump 1 fails to start because there is air in the main oil pump 1 and the main oil suction pipe 2, so that the main oil pump 1 and the auxiliary oil pump 4 can be...

Embodiment 3

[0027] On the basis of the above-mentioned embodiments, in this embodiment, the main oil outlet pipe 3 is provided with a main ball valve 11 communicating with the main oil outlet pipe 7, and the auxiliary oil outlet pipe 6 is provided with a ball valve communicating with the auxiliary oil outlet pipe 8. The auxiliary ball valve 12. The main ball valve 11 can be used to control the efficiency and stability of lubricating oil diverted from the main oil outlet pipe 3 to the main oil guide pipe 7, thereby ensuring that the air in the auxiliary oil pump 4 and the auxiliary oil suction pipe 5 can be completely discharged. Utilizing the main ball valve 11 also facilitates disconnecting the main oil outlet pipe 3 from the main oil guide pipe 7 . The auxiliary ball valve 12 plays the same role as the main ball valve 11.

[0028] In this embodiment, other contents not described are the same as those in the foregoing embodiments, so details are not repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com