Welding structure for annular-wave metal corrugated pipe, and production method thereof

A metal bellows, welded structure technology, applied in metal processing equipment, non-detachable pipe connections, pipes/pipe joints/pipe fittings, etc., can solve the problem of cracking caused by bending stress, unreliable weld quality, and waste of corrugated materials. and other problems, to achieve the effect of saving stainless steel materials, improving the reliability of welding and sealing, and reducing the stress on the welding seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

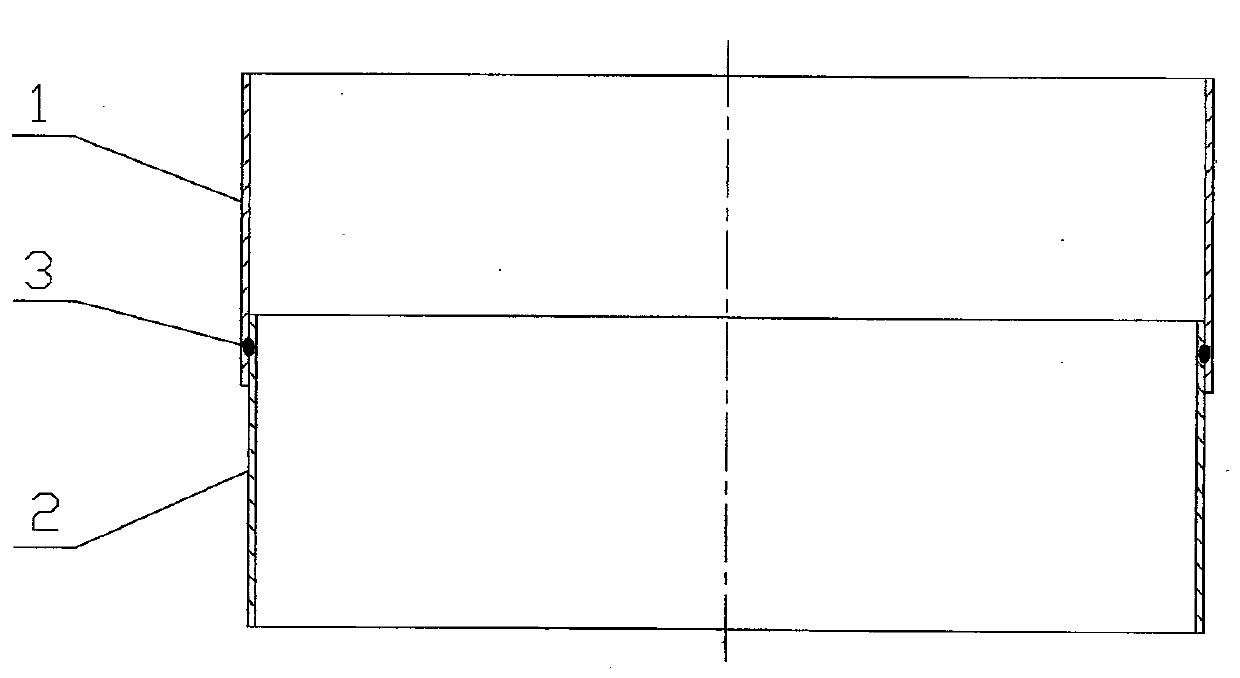

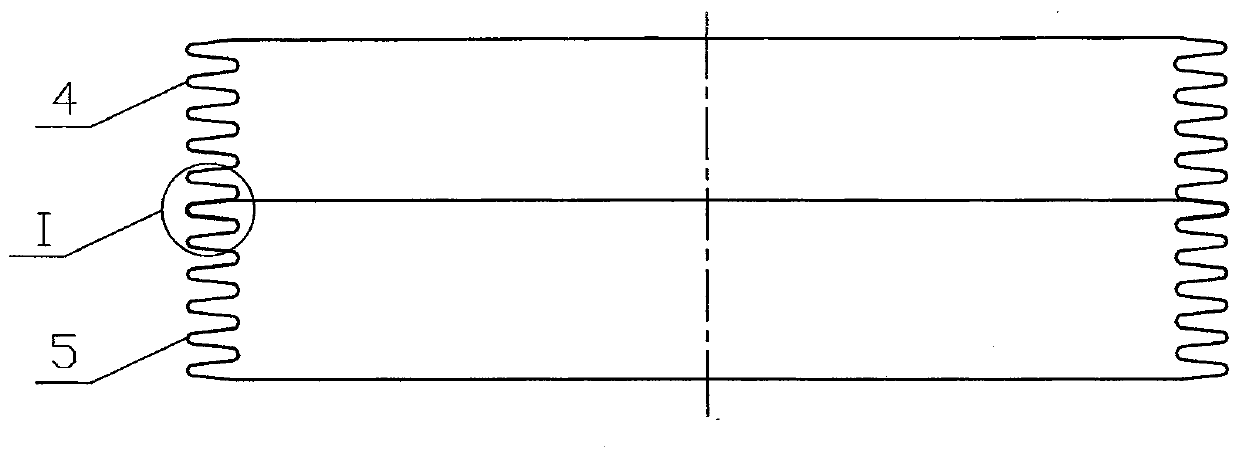

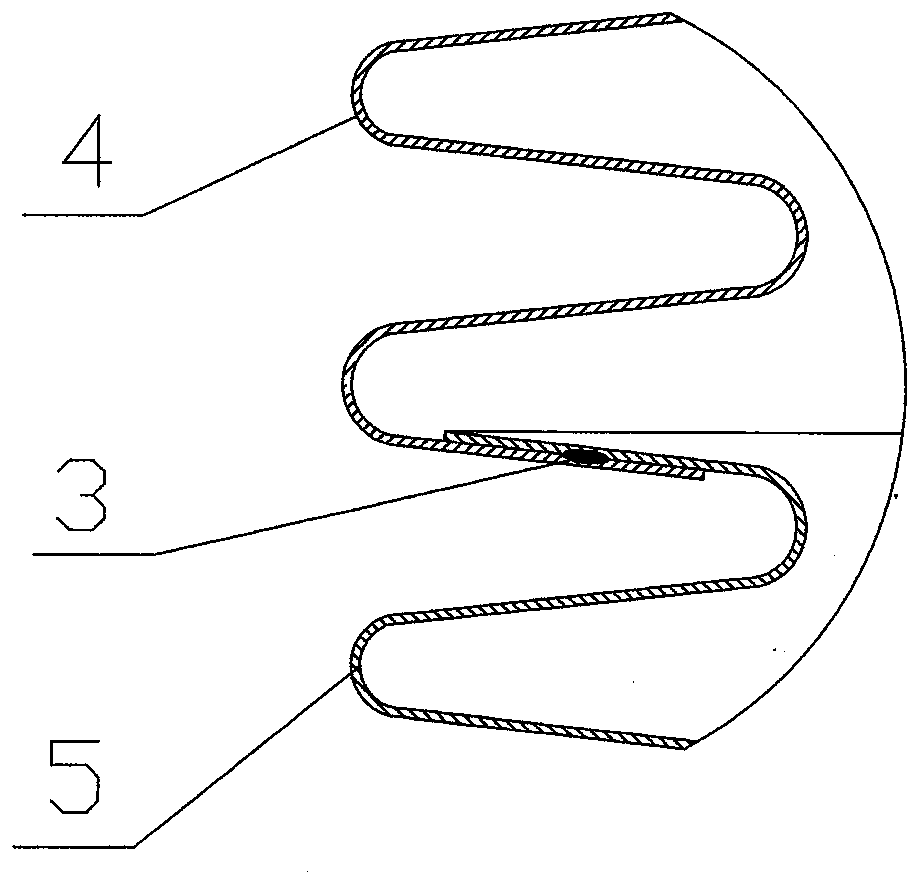

[0026] A manufacturing method of ring-wave metal bellows. The number of pipe blanks to be connected is determined according to the total number of corrugations actually required. First, the stainless steel coil is unrolled and blanked according to the circumference of the pipe blanks, and welded to form corrugated pipes. Tube blank A1 and tube blank B2 or more tube blanks. When determining the blanking size of the circumference of the tube blank, let the adjacent tube blanks meet the requirements of tight socket. Then two or more tube blanks are nested end to end at adjacent ends and partially overlapped (that is, overlapped), such as figure 1 , the amount of lap overlap can meet the forming and welding requirements. Then use a seam welding machine (also known as a seam welding machine) with a disc electrode to perform seam welding at the overlap to form a weld 3. The welding current and welding speed are adjusted to the welding point that the weldment is fully fused and the ...

Embodiment 2

[0028] Such as Figure 4 As shown, the overlapping seam welding seam 3 is set in the crest area of the corrugation during forming, and the rest is the same as the first embodiment.

Embodiment 3

[0030] Such as Figure 5 As shown, the seam welding seam 3 at the overlap is set in the trough area of the corrugation during forming, and the rest is the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com