Steel sheet stacking device for wind turbine tower barrel production

A technology for wind power towers and steel plates, which is applied in the field of steel plate stacking devices for wind power tower production, which can solve problems such as increased difficulty, rust on the surface of steel plates, and increased production costs, and achieve the effect of facilitating hoisting and transportation and reducing the degree of rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to facilitate the understanding of those skilled in the art, the structure of the present invention will be further described in detail with the embodiments in conjunction with the accompanying drawings:

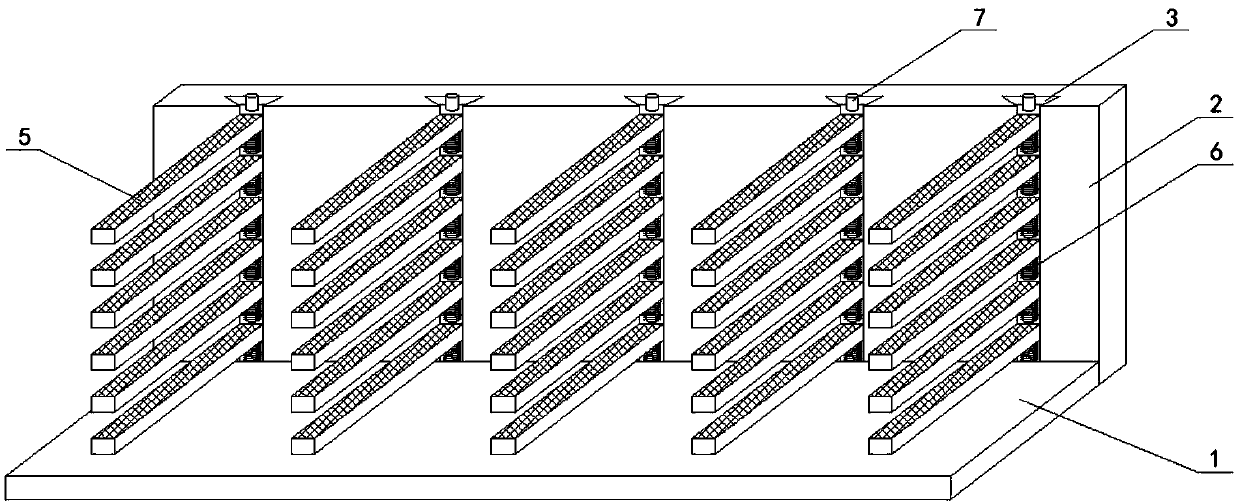

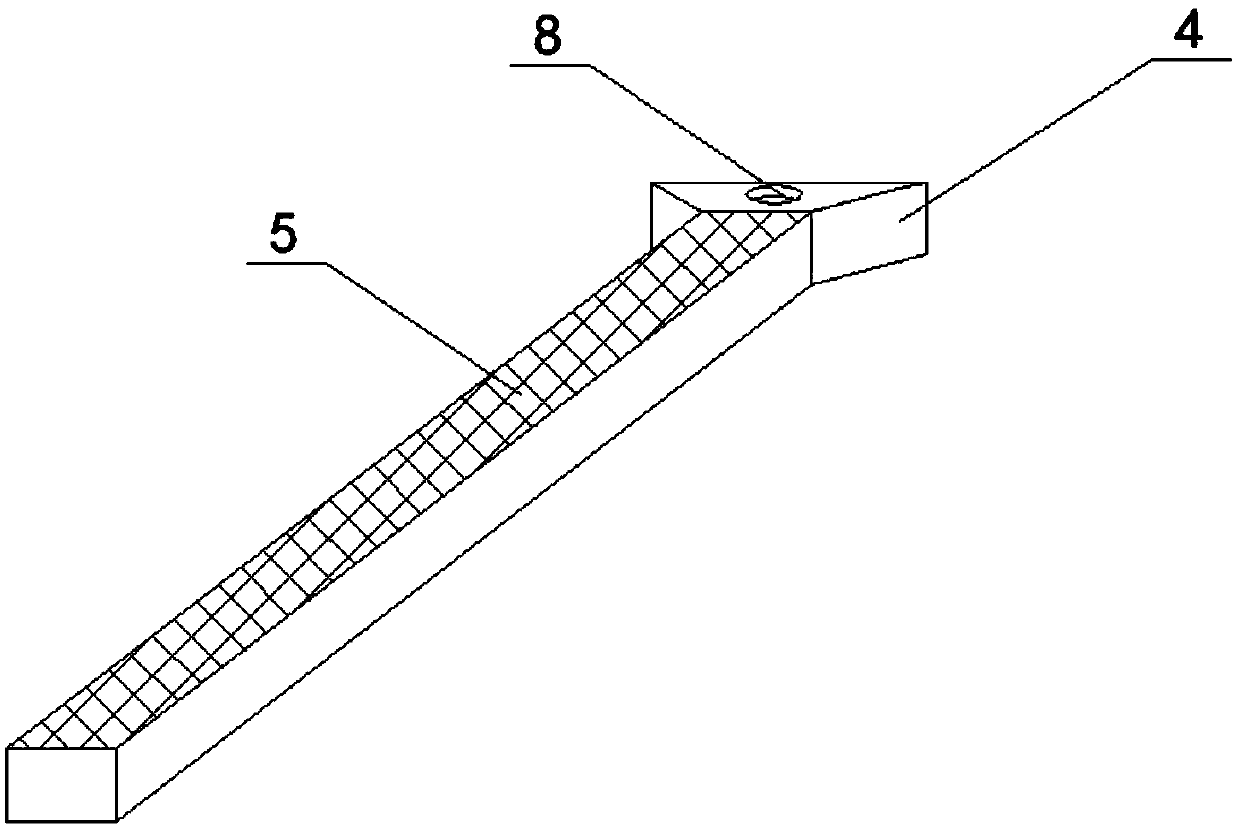

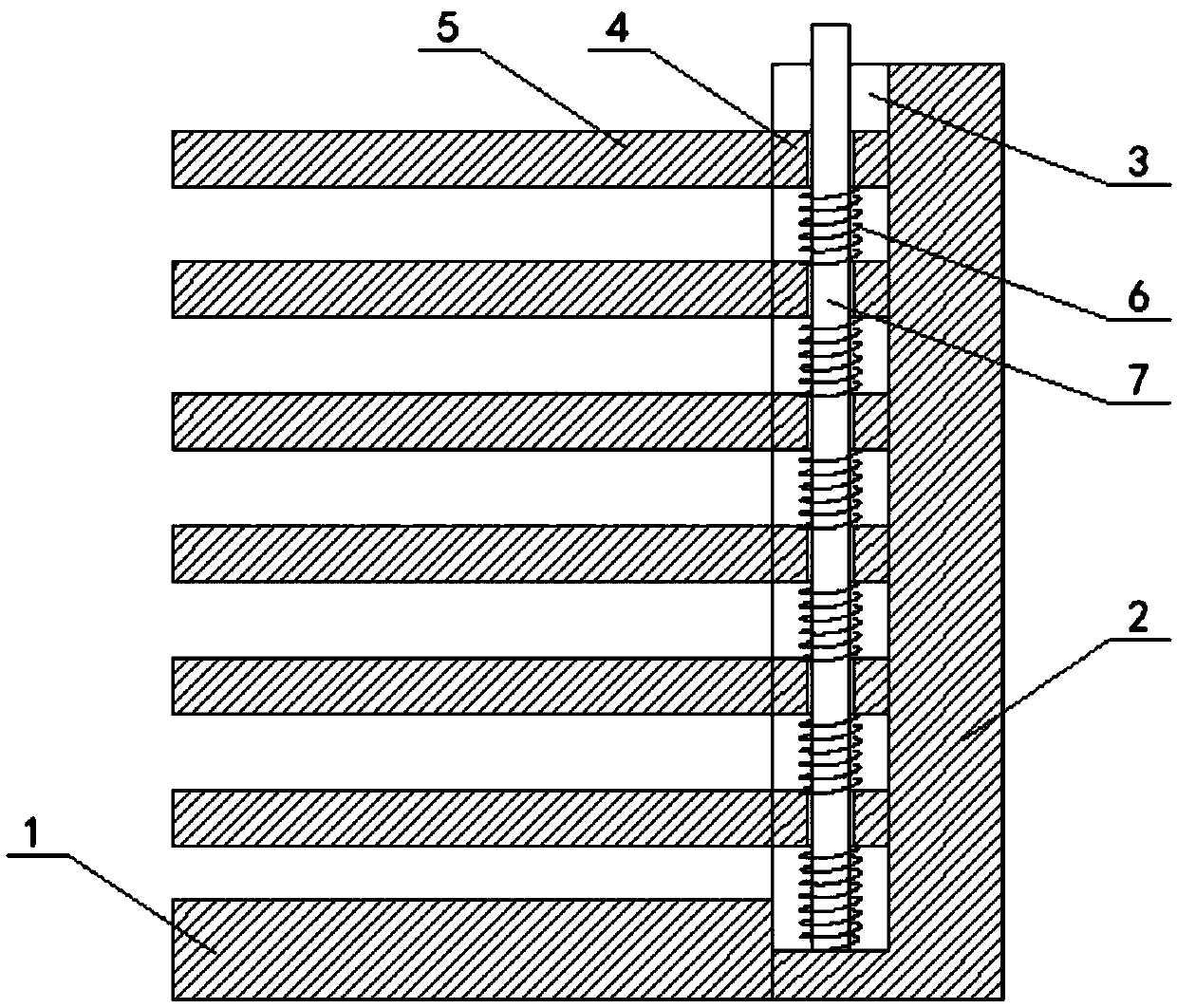

[0018] refer to Figure 1-4 , a steel plate stacking device for wind power tower production, comprising a positioning base 1 and a positioning plate 2 vertically fixed on one side of the positioning base 1, the positioning plate 2 is provided with a plurality of vertically arranged inverted Trapezoidal locating groove 3, the bottom of described inverted trapezoidal locating groove 3 is positioned at the surface below of described positioning base 1; In described inverted trapezoidal locating groove 3, there are a plurality of corresponding inverted trapezoidal slide blocks 4 according to the height movable device, The outer sides of the inverted trapezoidal sliders 4 are respectively affixed with corresponding isolation support rods 5, and corresponding posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com