A Combined Electromagnetic Eddy Current Braking Device

An electromagnetic eddy current and braking device technology, applied in electric braking systems, electric vehicles, motor vehicles, etc., can solve problems such as poor reliability, and achieve fast heat dissipation, clear working principle, and uniform heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

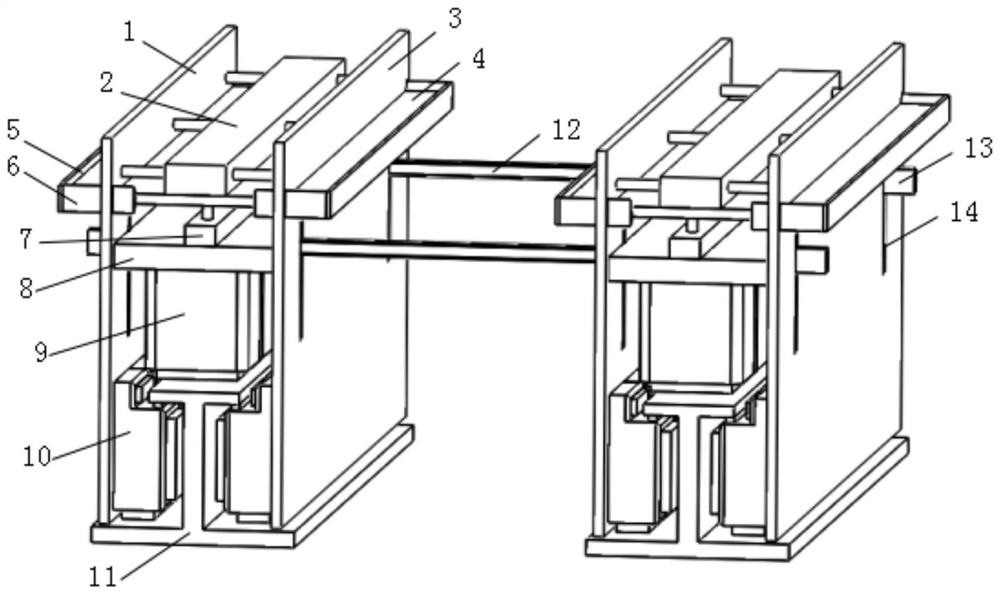

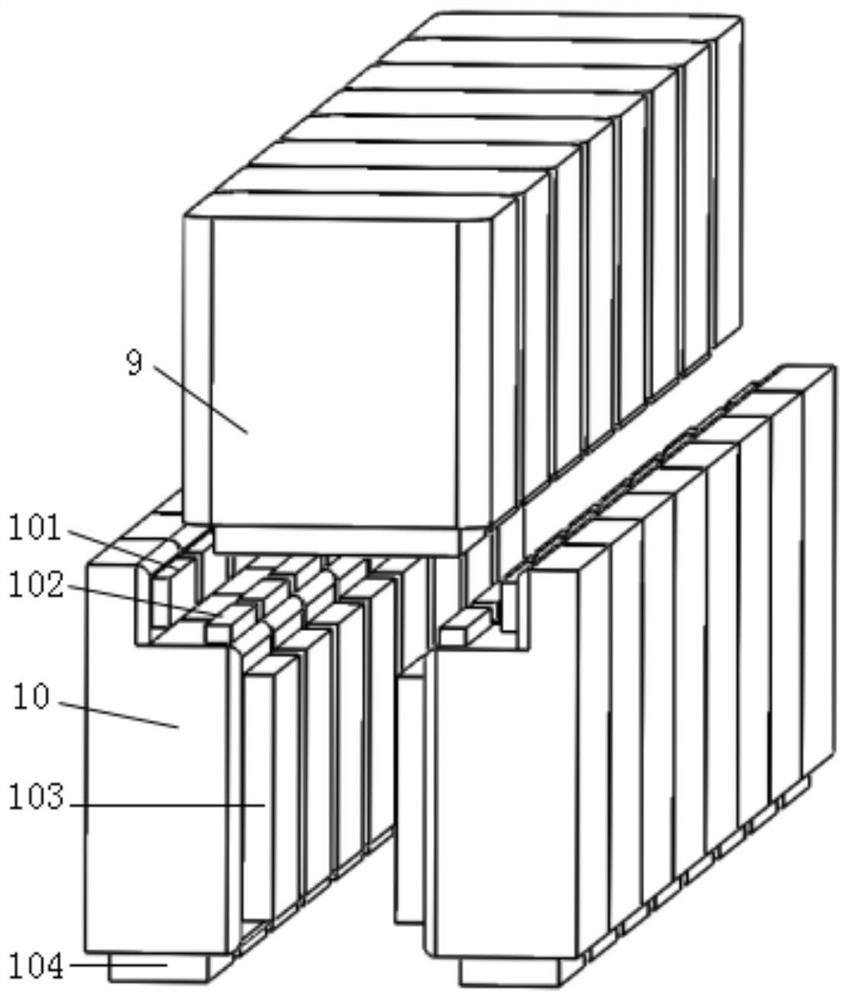

[0016] The present invention will be further described below in conjunction with accompanying drawing:

[0017] Such as Figure 1-2 As shown, a combined electromagnetic eddy current braking device is composed of a left braking mechanism, a right braking mechanism and a connecting beam 12; both the left braking mechanism and the right braking mechanism are composed of an outer plate 1 , inner board 3, upper hydraulic device 2, lower hydraulic device 7, main supporting board 8, second supporting board 4, trapezoidal guide rail 6, square coil 9, L-shaped coil 10 and rail 11 are connected; outer board 1 and inner side The plate 3 is slidingly connected with the second support plate 4 through the trapezoidal guide rail 6, the two outer surfaces of the second support plate 4 are connected with the second support plate baffle 5, and the upper hydraulic device 2 is fixedly arranged above the second support plate 4, The piston rods of the upper hydraulic device 2 are fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com