Buffer device for welding wire, welding system and welding robot

A buffer device, welding device technology, applied in welding equipment, welding accessories, arc welding equipment and other directions, can solve the problems of increasing the weight burden of welding workers, unfavorable storage and arrangement, and unfavorable manual welding, etc., to improve economic practicability , Shorten the production cycle and reduce the effect of wire blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

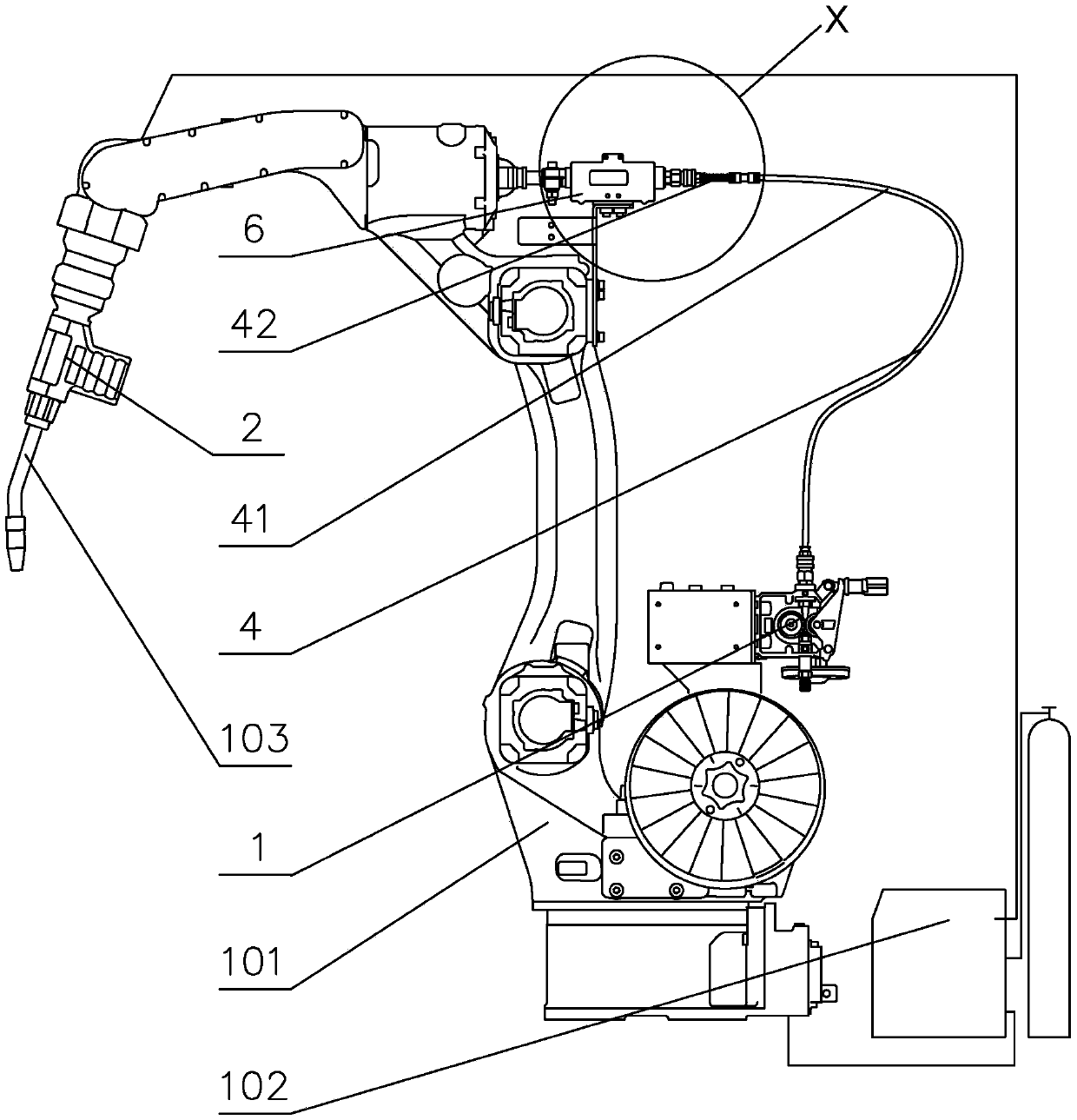

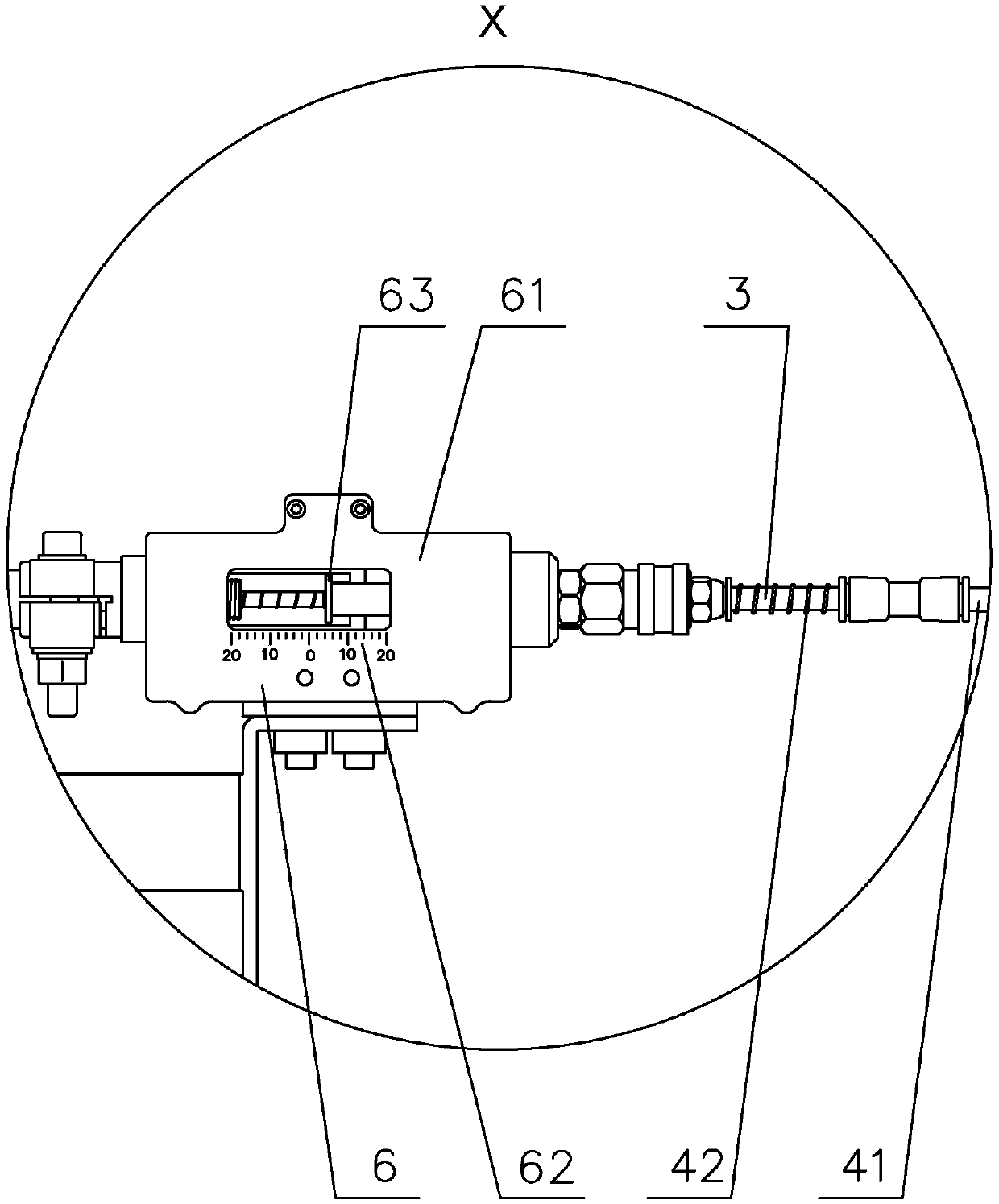

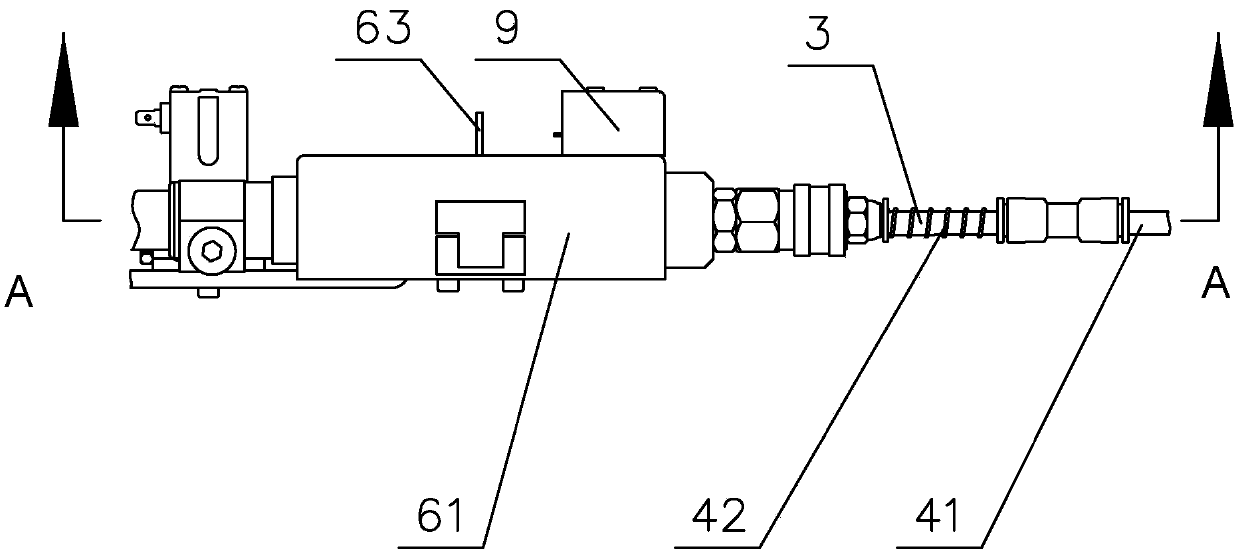

[0045] figure 1 It is a structural schematic diagram of a welding robot applying a buffer device for welding wire in an embodiment of the present invention. Such as figure 1 As shown, the welding robot includes a welding robot 101 , a welding power source 102 , a welding torch 103 , a first wire feeding unit 1 , a second wire feeding unit 2 , a wire feeding inner tube 3 , a wire feeding sleeve 4 , and an indicating unit 6 . The welding torch 103 is arranged at the end of the welding robot body 101 ; the welding torch 103 , the first wire feeding part 1 and the second wire feeding part 2 are respectively electrically connected to the welding power source 102 . The indicating part 6 is arranged between the first wire feeding part 1 and the second wire feeding part 2 on the side close to the second wire feeding part 2, the indicating part 6 is fixed on the welding device, the wire feeding inner tube 3, the wire feeding sleeve The tube 4 is provided between the first wire feedin...

Embodiment 2

[0073] The structure of embodiment 2 is the same as that of embodiment 1, the main difference is that both ends of the wire feeding sleeve hose 41 in embodiment 2 are respectively fixed to the wire feeding inner tube 3, and the wire feeding inner tube 3 cannot be placed on the wire feeding sleeve hose. 41 to increase the length, it can only move in the elastic tube 42, the gap between the wire feeding sleeve 4 and the wire feeding inner tube 3 in embodiment 1 is small enough, so that the wire feeding inner tube 3 is inside the wire feeding sleeve 4 Can only move axially.

[0074] Such as Figure 1 to Figure 4 As shown, the wire feeding sleeve hose 41 and the wire feeding inner tube 3 are fixed on the first wire feeding part 1, and the wire feeding inner tube 3 sequentially passes through the wire feeding sleeve hose 41 and the elastic tube 42 and extends into the indicating part 6, Both ends of the wire feeding sleeve flexible pipe 41 are fixed with the wire feeding inner tub...

Embodiment 3

[0076] The structure of embodiment 3 is consistent with that of embodiment 1, the main difference is that the length direction of the wire feeding sleeve 4 in embodiment 3 is an axially retractable elastic tube 42, and the wire feeding sleeve 4 in embodiment 1 includes The axially stretchable elastic tube 42 and the axially incompressible or very small guide hose 41 are compressed.

[0077] Since the elastic tube 42 determines the maximum buffering capacity of the welding wire, in order to achieve the largest possible buffering capacity of the welding wire, the wire feeding sleeve 4 is used as the elastic tube 42 whose length direction is axially expandable. In addition, the use of elastic tube 42 for the whole wire feeding sleeve 4 can reduce the parts used for the whole device of the buffer device for welding wire, reduce the management requirements of parts, reduce the assembly process and related process requirements in the device manufacturing process, and reduce managemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com