Cold finishing production line for gears of multiple specifications and machining process thereof

A cold finishing, production line technology, applied in metal processing equipment, wheels, manufacturing tools, etc., can solve the problem of not having a set of efficient and complete automation equipment, and achieve the effect of simple and easy working principle, less manpower and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

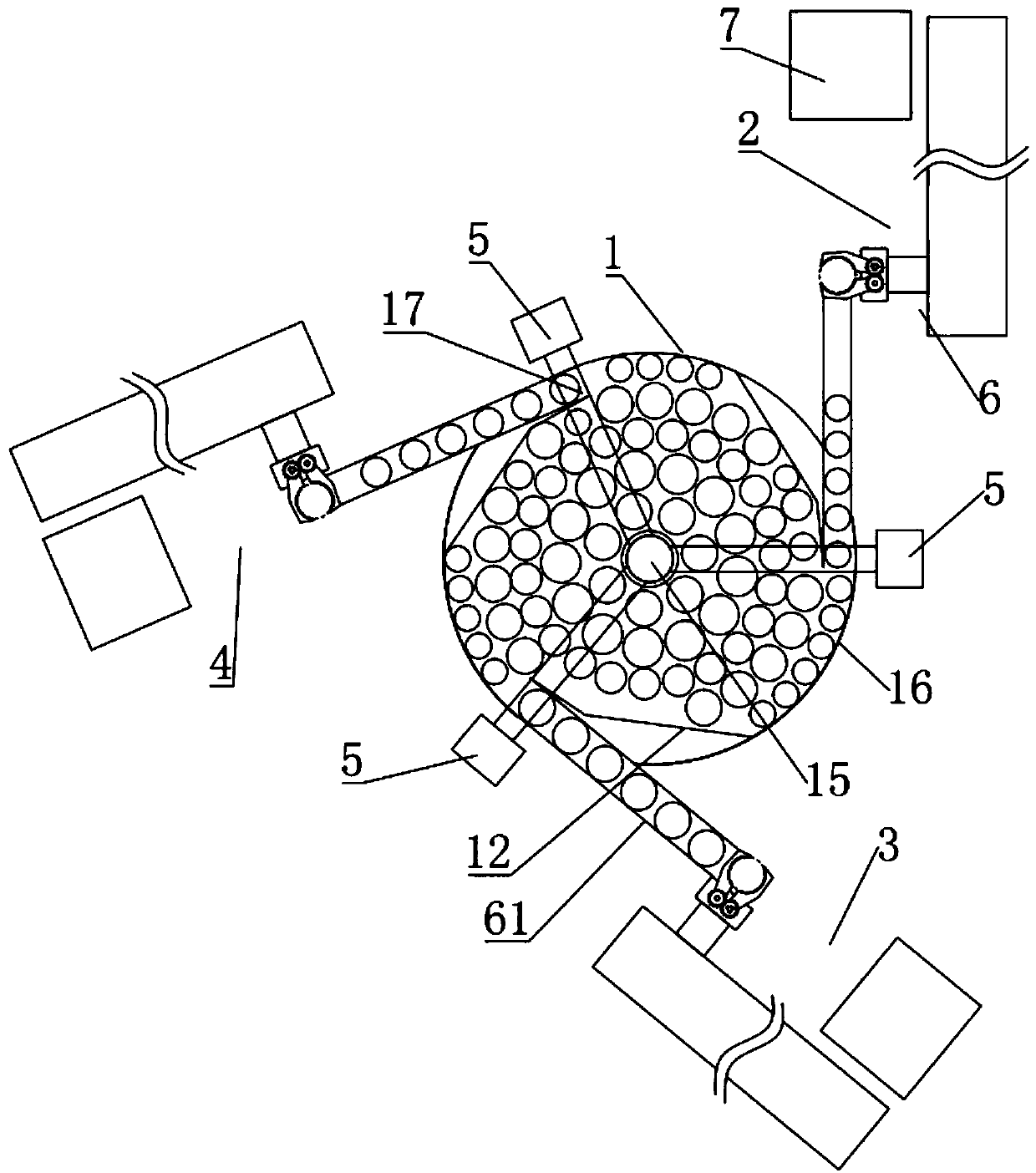

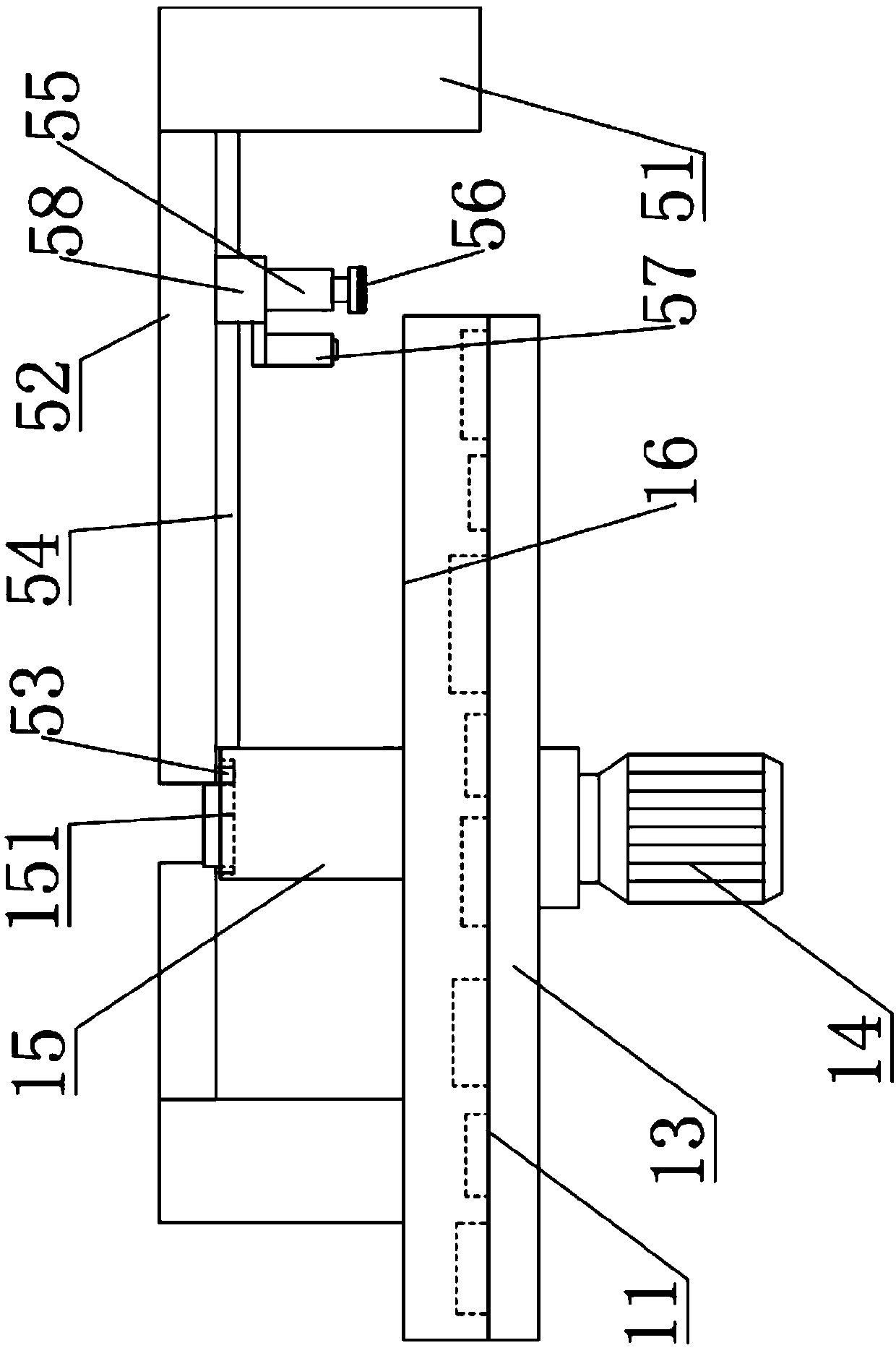

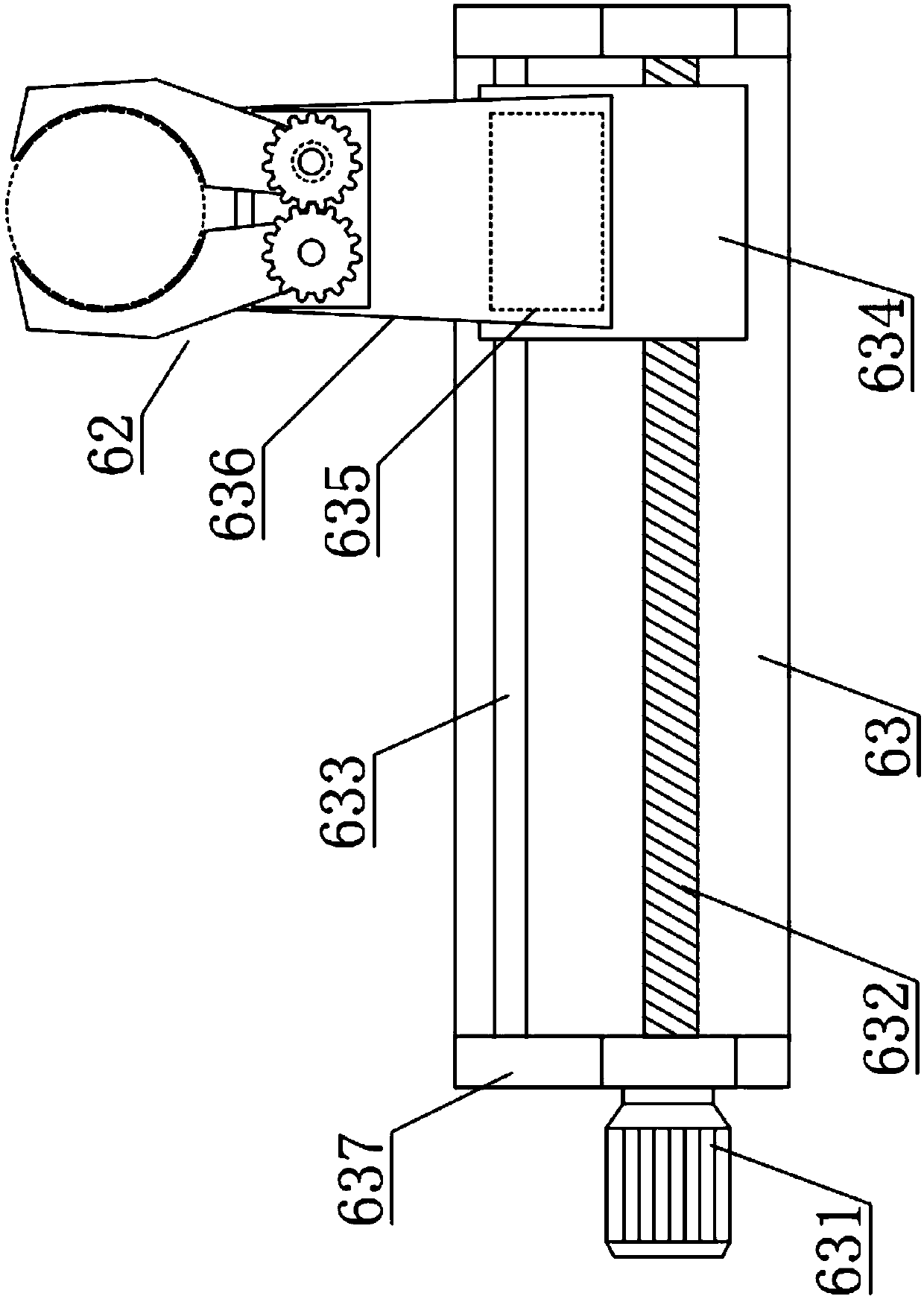

[0046] like figure 1 , 2 The cold finishing production line of gears of multiple specifications shown includes a turntable 1, a first cold finishing unit 2, a second cold finishing unit 3 and a third cold finishing unit 4, and the turntable 1 is a circular turntable, so The first cold finishing unit 2, the second cold finishing unit 3 and the third cold finishing unit 4 are evenly spaced outside the circumference of the turntable 1, and the first cold finishing unit 2 and the second cold finishing unit The unit 3 and the third cold finishing unit 4 work independently of each other; wherein, the first cold finishing unit 2, the second cold finishing unit 3 and the third cold finishing unit 4 all include a tooth profile detection assembly 5, a gear Feeding assembly 6 and gear cold finishing assembly 7, one end of the tooth shape detection assembly 5 is connected with the turntable 1, the gear feeding assembly 6 is connected with the outer circumference of the turntable 1, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com