Grain preparation machine control device

A control device, grain technology, applied in the direction of computer control, program control, grain processing, etc., to achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

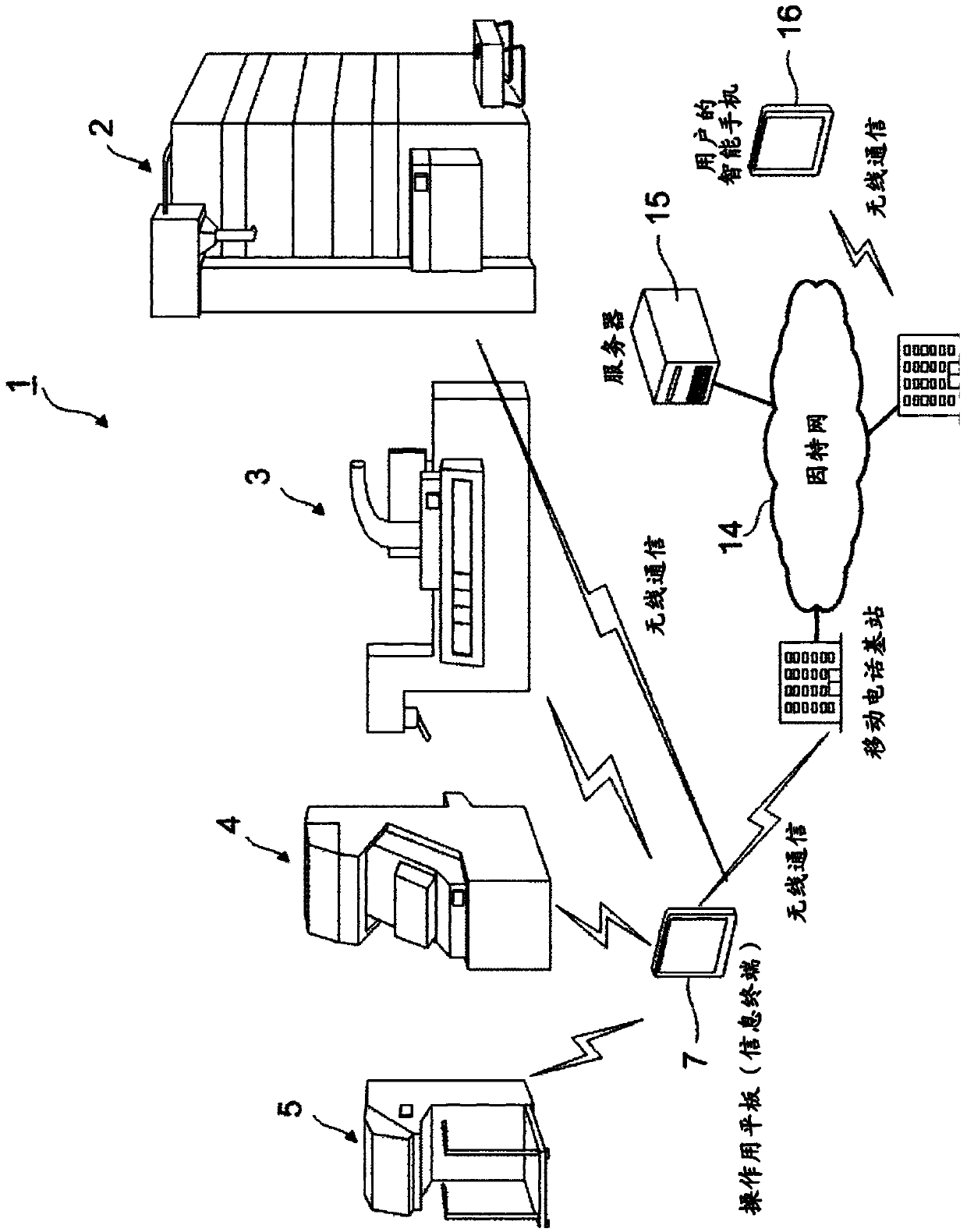

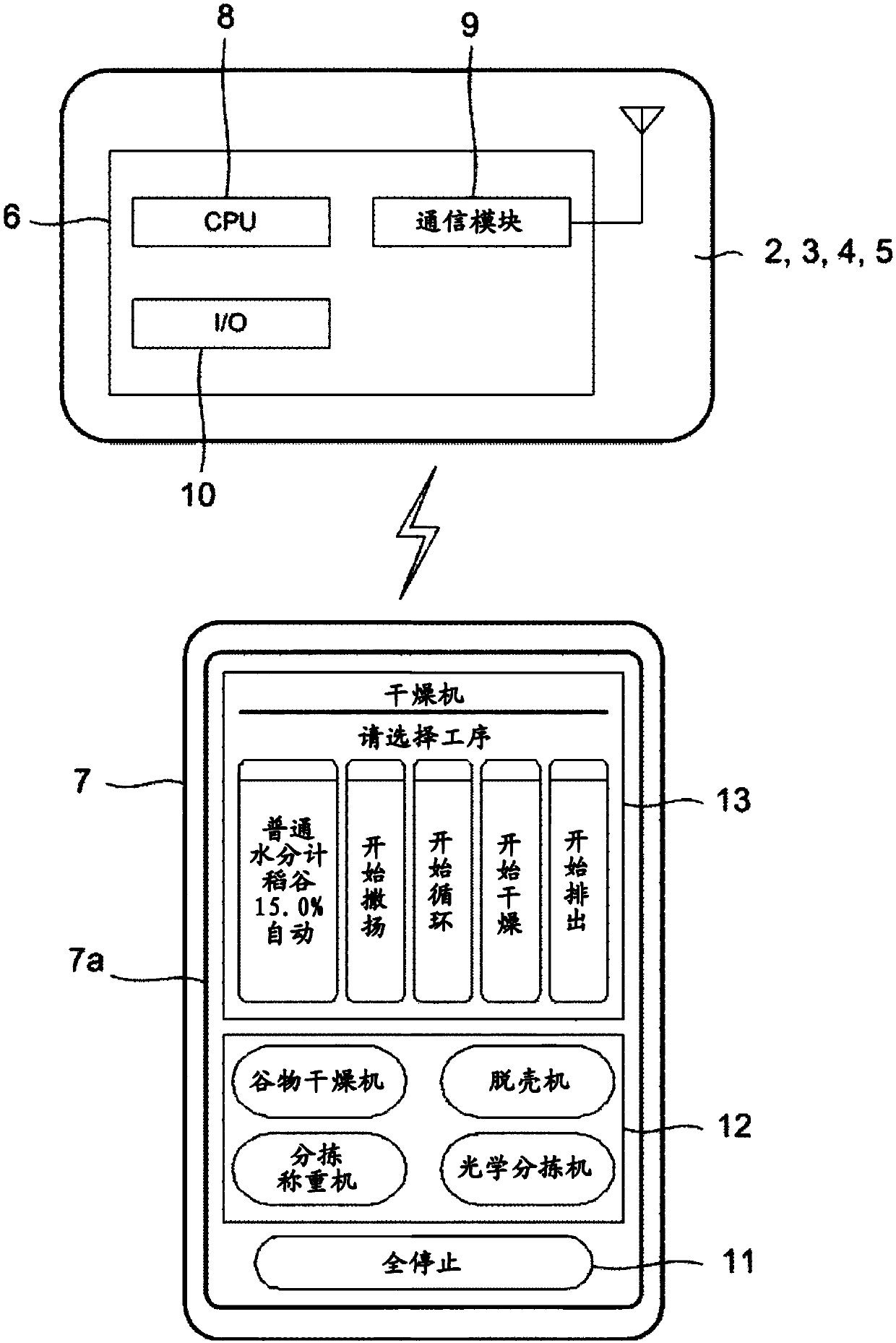

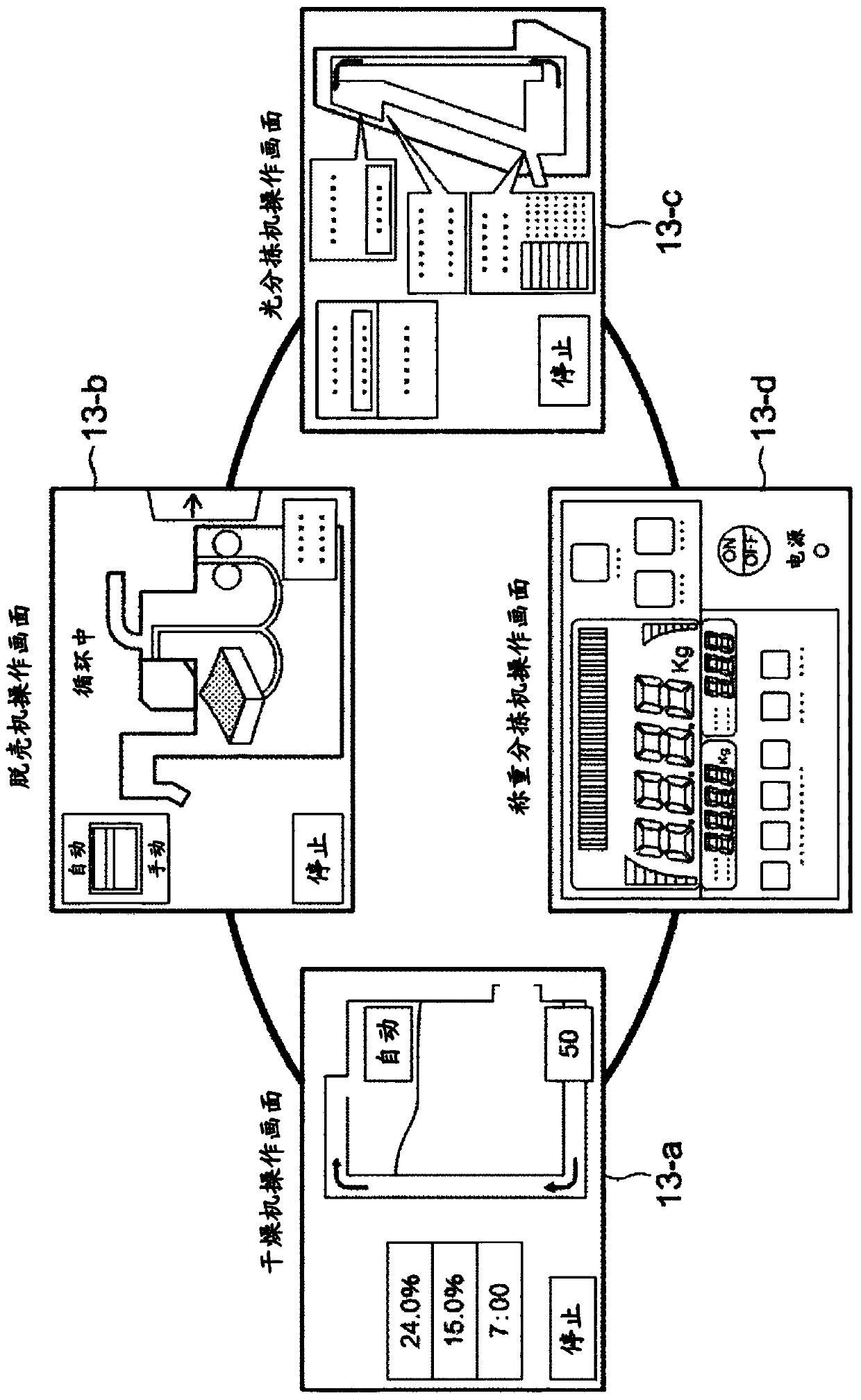

[0029] Hereinafter, suitable embodiments of the present invention will be described based on the drawings. figure 1 It is a conceptual diagram of an embodiment of the control device of the grain preparation machine of the present invention, figure 2 Is a schematic block diagram of the control device, image 3 It is an individual setting transition diagram when selecting each grain preparation machine.

[0030] Such as figure 1 As shown, the control device 1 of the grain preparation machine can be applied to the grain dryer 2 for preventing the deterioration of the harvested grain, improving the storage property, and the processability. 2. The grain husk is removed from the grain and processed into coarse rice. The purpose of the hulling machine 3, the optical sorting machine that optically sorts defective grains and foreign objects from the hulled coarse rice, and the optical sorter 4 sorts and removes the millet and broken particles contained in the optically sorted coarse rice a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com