Flexible optical-fiber ribbon

A technology of optical fiber ribbon and optical fiber, applied in the field of optical fiber ribbon, can solve the problems that non-planar optical fiber ribbon is not suitable for multi-channel fusion splicing operation, insufficient efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

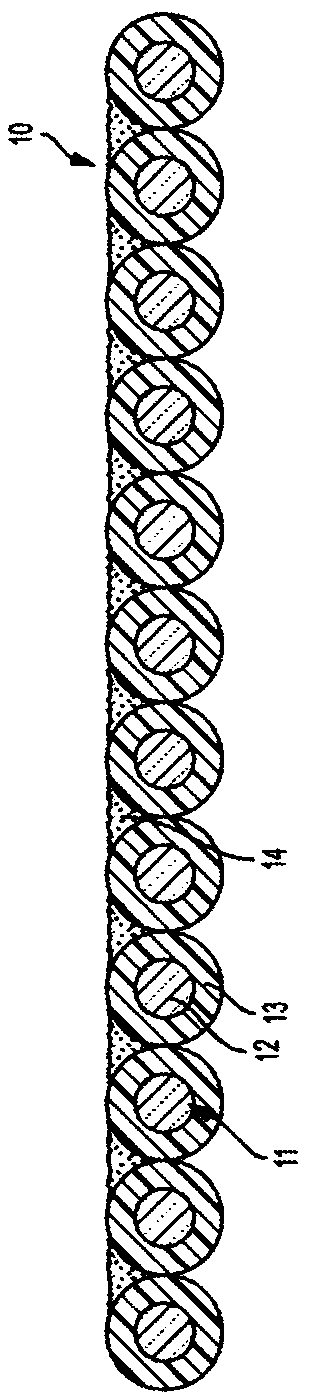

[0016] In one aspect, the invention includes flexible fiber optic ribbons that can be folded or crimped into a compact shape and then unfolded or unfolded into a planar configuration of parallel fibers without disrupting the ribbon structure or damaging the constituent fibers. In a substantially planar geometry, the flexible fiber optic ribbon facilitates multi-way fusion splicing. In substantially non-planar geometries, flexible fiber optic ribbons facilitate increased space efficiency within fiber optic cable structures such as micromodules or buffer tubes.

[0017] like Figure 1-4 As shown, the exemplary flexible fiber optic ribbons 10 each include a plurality of optical fibers 11 arranged side-by-side in such a manner that the optical fibers 11 are substantially parallel to each other. Individual optical fibers 11 comprising component glass fibers 12 and one or more surrounding coating layers 13 may be closely spaced or contiguous with adjacent optical fibers 11 , but ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com