Lead plate fracture prevention separating block and fixed installation method thereof

A barrier block and lead plate technology, applied in the direction of lead-acid batteries, lead-acid battery construction, sustainable manufacturing/processing, etc., can solve the problems of overall battery damage, differences in the movement state of lead blocks and battery shells, battery collisions, etc., to achieve The method is simple and easy to understand, avoiding the breakage of the lead plate, and the effect of reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in combination with specific embodiments.

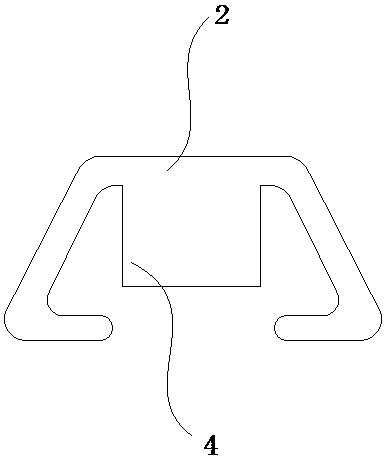

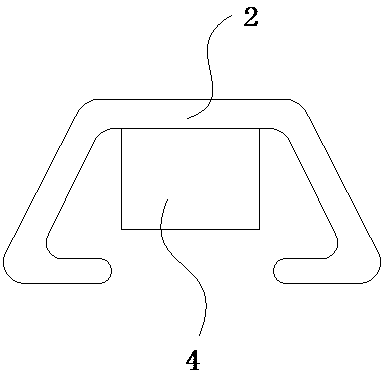

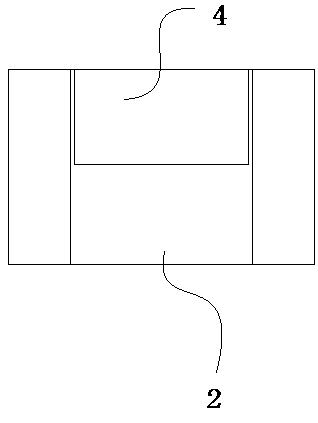

[0028] Such as Figure 4 As shown, a barrier block for preventing the lead plate from breaking includes a battery case 5 and a lead plate 6, and the lead plate 6 is arranged in a grid shape in the battery case 5, and the lead plate 6 and the casing of the battery case 5 There is a gap between them, that is, the lead plate 6 and the battery case 5 are not fully attached. A blocking block 1 is arranged in the gap between the lead plate 6 and the battery case 5, and the blocking block 1 is composed of horizontal grid plates A2, 2 It consists of an oblique grid plate B3 and a fixed block 4.

[0029] The grid plate A2 and the grid plate B3 are plate-shaped, the two ends of the horizontal grid plate A2 are respectively fixedly connected with the oblique grid plate B3, the lower surface of the grid plate A2 is fixedly connected with the barrier block 1, and the barrier block 1 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com