A warehouse location allocation method based on two-factor optimization

A space allocation, two-factor technology, applied in the direction of instruments, data processing applications, resources, etc., can solve the problems of inability to form electronic data, rely on front-line operators and inapplicability of historical operation information, and achieve low calculation overhead time cost, The effect of high utilization rate of warehouse historical experience and outbound data and low cost of system use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

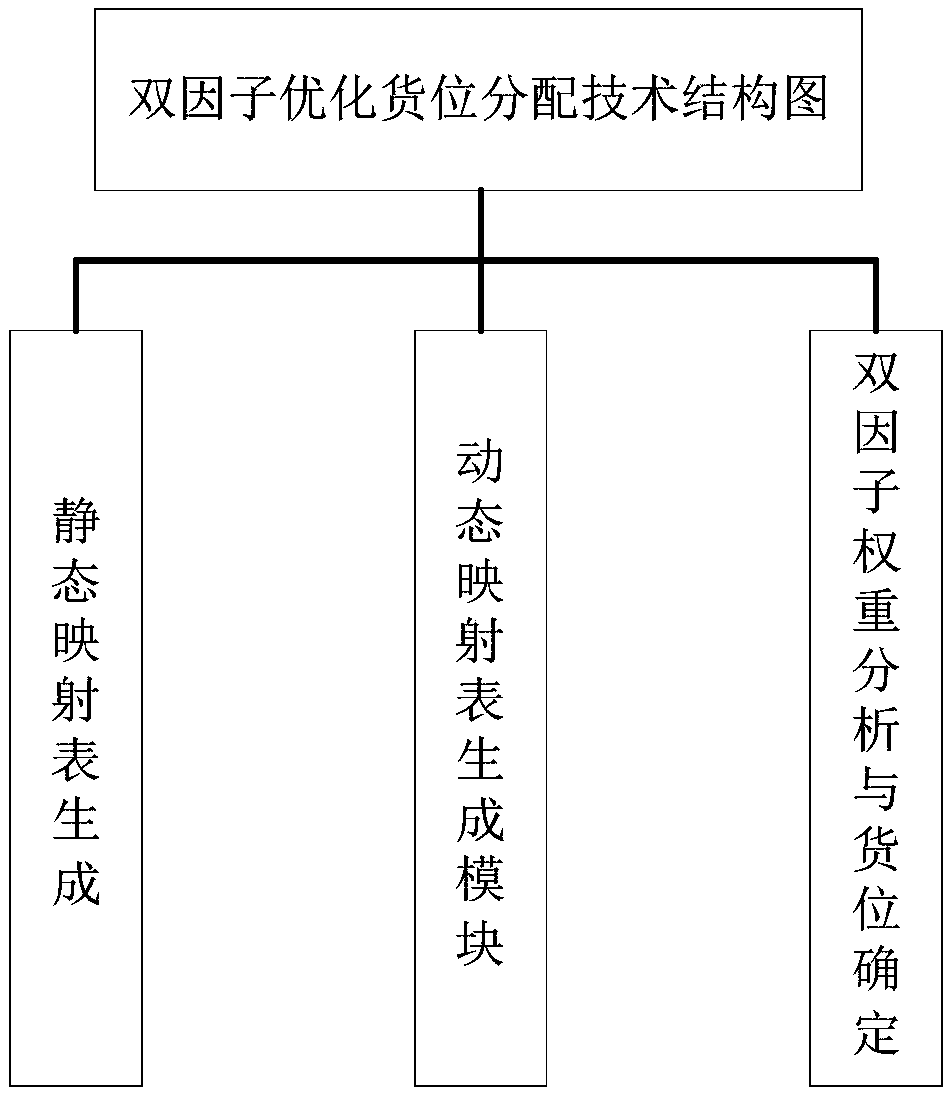

[0051] The two-factor optimization space allocation technology such as figure 1 It includes three parts: static mapping table generation module, dynamic mapping table generation module, two-factor weight analysis and cargo location determination module. The specific implementation includes the following steps:

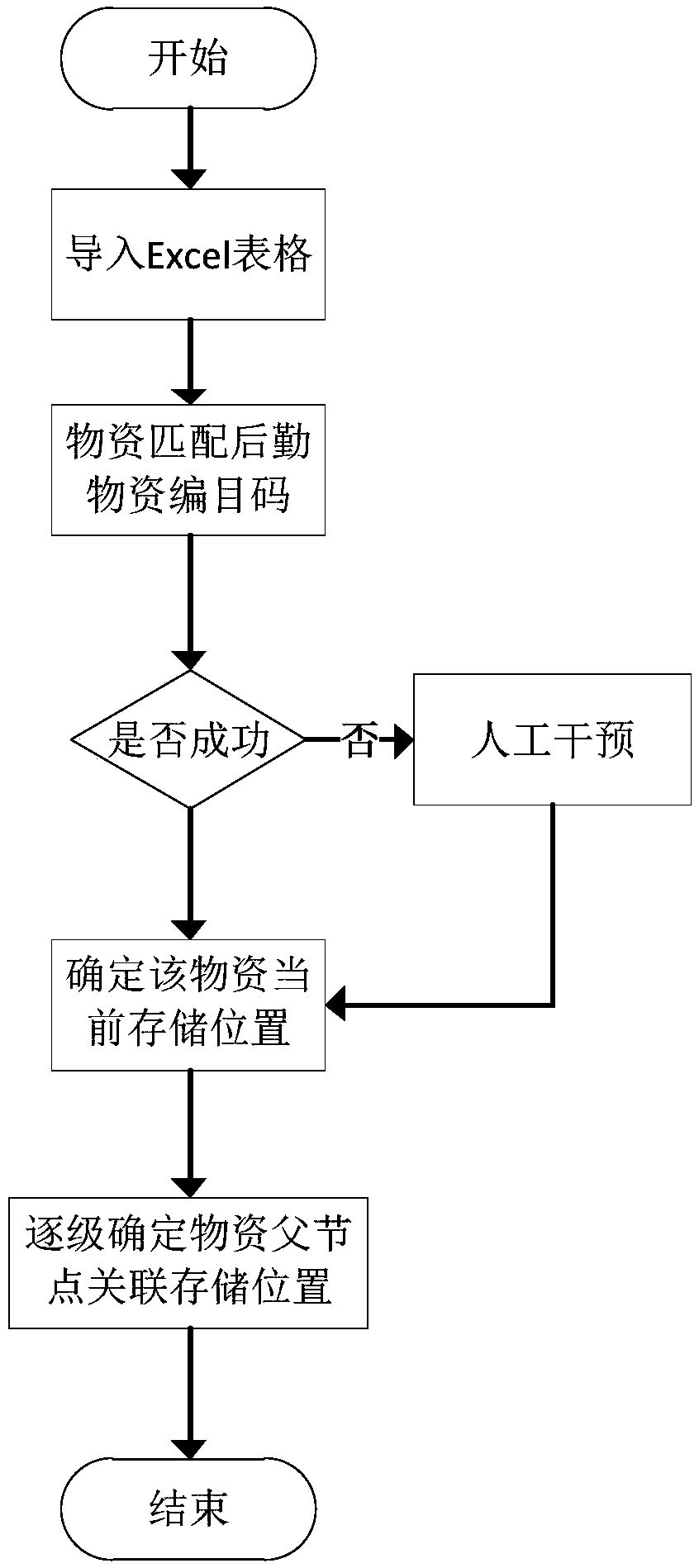

[0052] (1) The working mode of the static mapping table generation module is as follows figure 2 shown. First, the module needs to import an Excel table, which can be formed by manual statistics, or can be exported by existing warehouse management software to record the materials and storage locations currently stored in the warehouse; Match the material names in the warehouse material cataloging code to determine the position of the material in the warehouse in the tree cataloging system. If it cannot be identified, provide a means of manual intervention to determine the warehouse material cataloging code for the warehouse material; then, to determine the catalogin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com