Large-caliber optical reflector with back flexible supporting structure

A flexible support and mirror technology, used in optics, optical components, installation, etc., can solve the problems of large size and quality of the support backplane, high surface accuracy requirements, and too many supporting links, and achieve precise installation positioning, reducing Small changes, improved effect of gravity deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

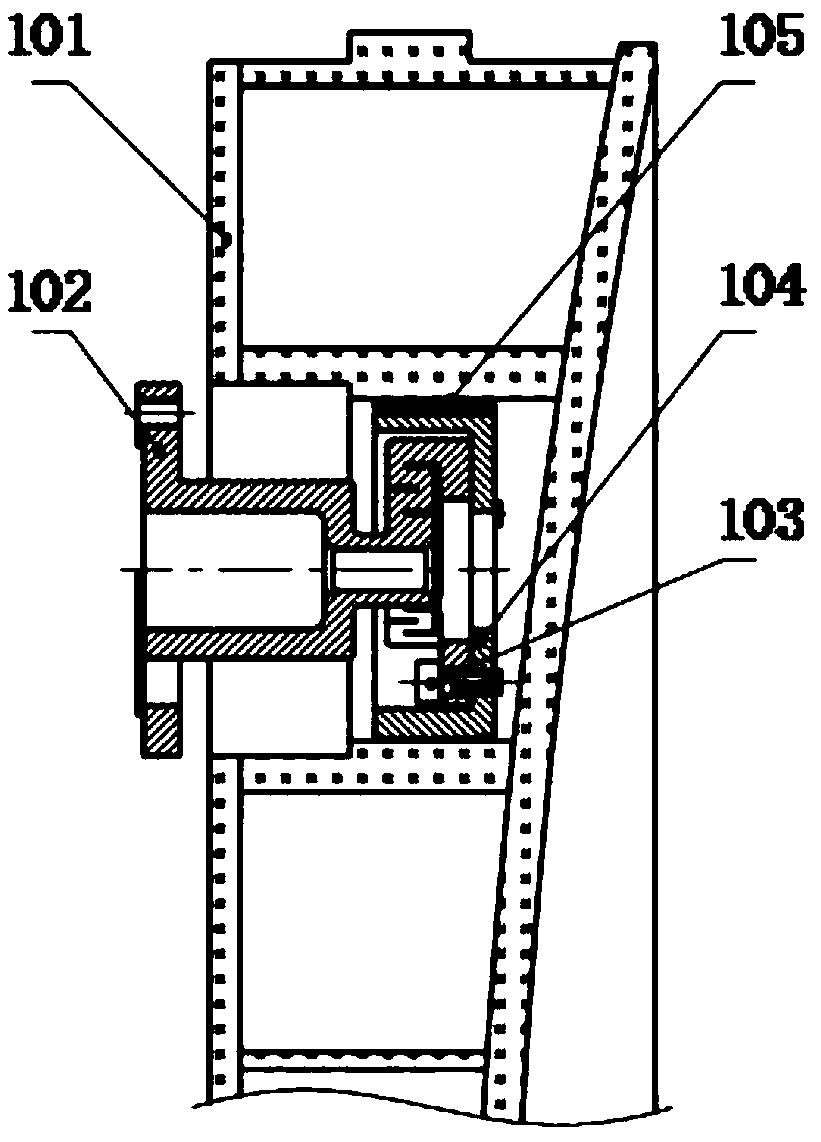

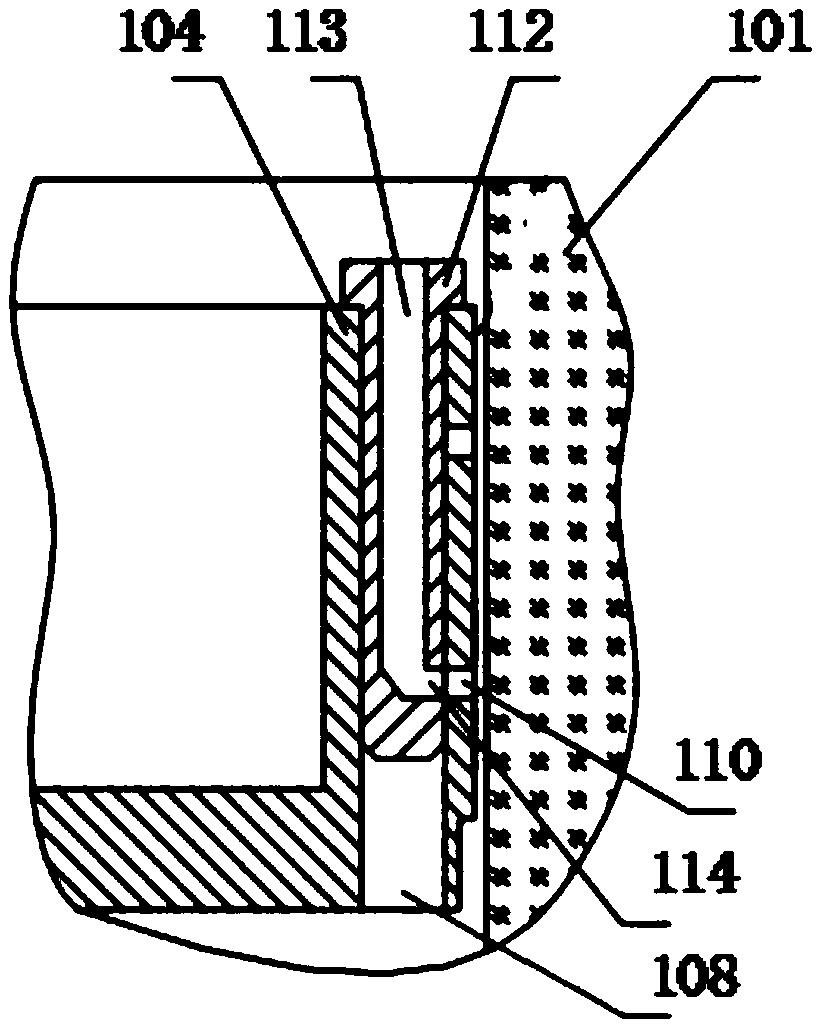

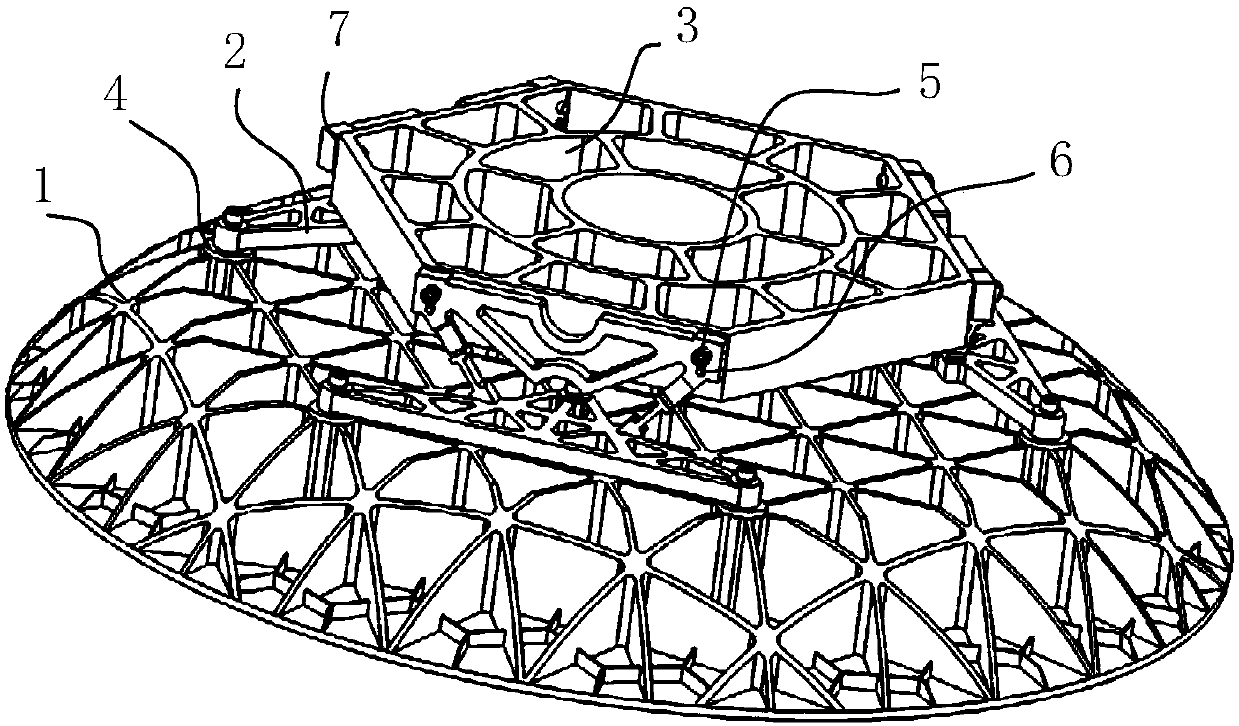

[0048] See attached image 3 to attach Figure 7 , the large-aperture optical mirror with a back flexible support structure of the present invention includes a mirror body 1 , a flexible bracket 2 and a supporting back plate 3 .

[0049] The connection relationship of the mirror structure is:

[0050] There are three flexible brackets 2, which are uniformly distributed between the mirror body 1 and the support back plate 3 along the circumferential direction;

[0051] Each flexible support 2 all comprises the isosceles triangle underframe 21 and the trapezoidal stand 22 that are vertically arranged; The sides are connected with the isosceles triangle underframe 21, and the bottom edge of the trapezoidal stand 22 is connected with the side of the supporting backboard 3;

[0052] The bottom edge of the trapezoidal stand 22 adopts a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com