Electronic yarn tension meter for textiles

A yarn tension, electronic technology, applied in tension measurement, application of stable tension/pressure testing material strength, instruments, etc., can solve the problem of inability to meet large-scale product testing, product quality and qualification rate reduction, single function, etc. problem, to achieve the effect of convenient card installation of water spray pipes, increased use effect, and strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

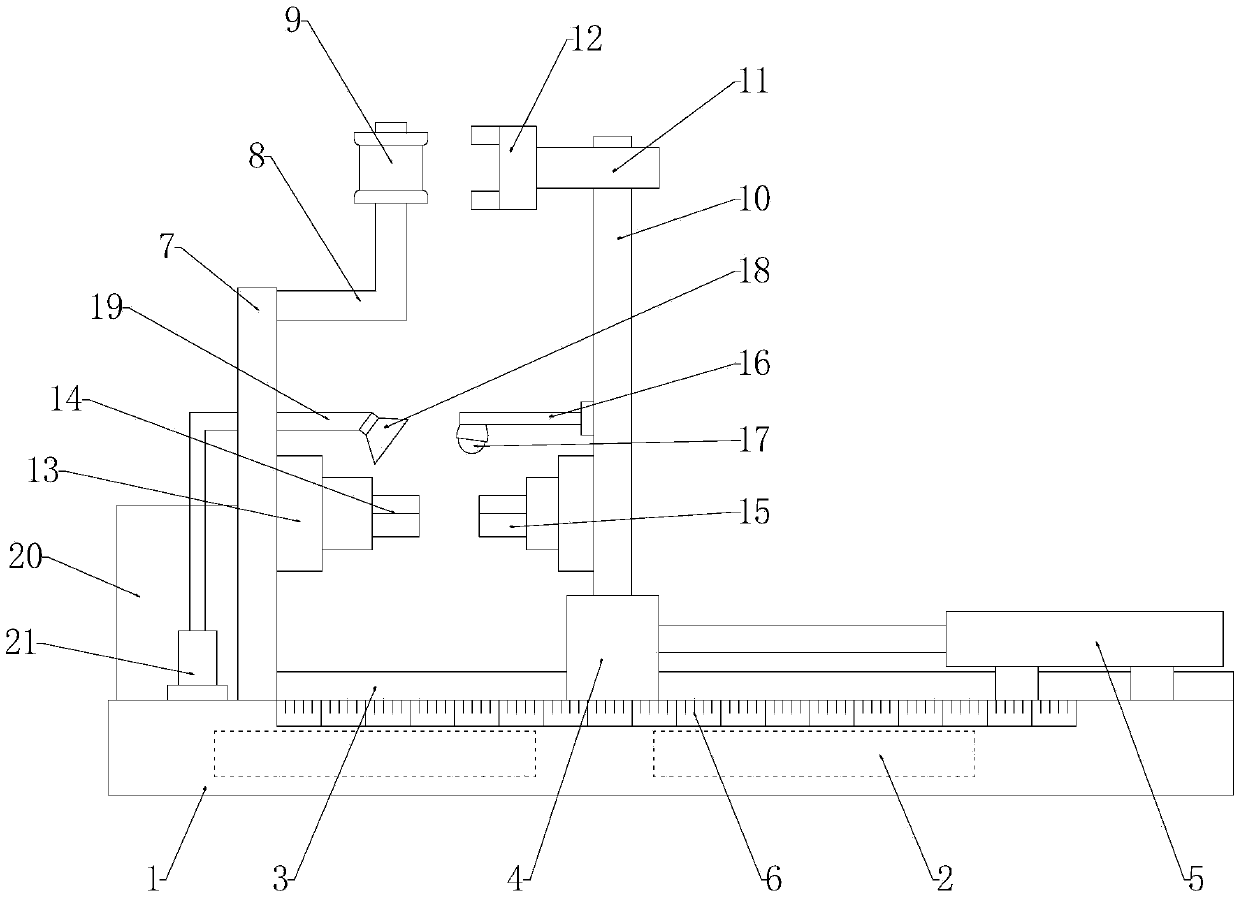

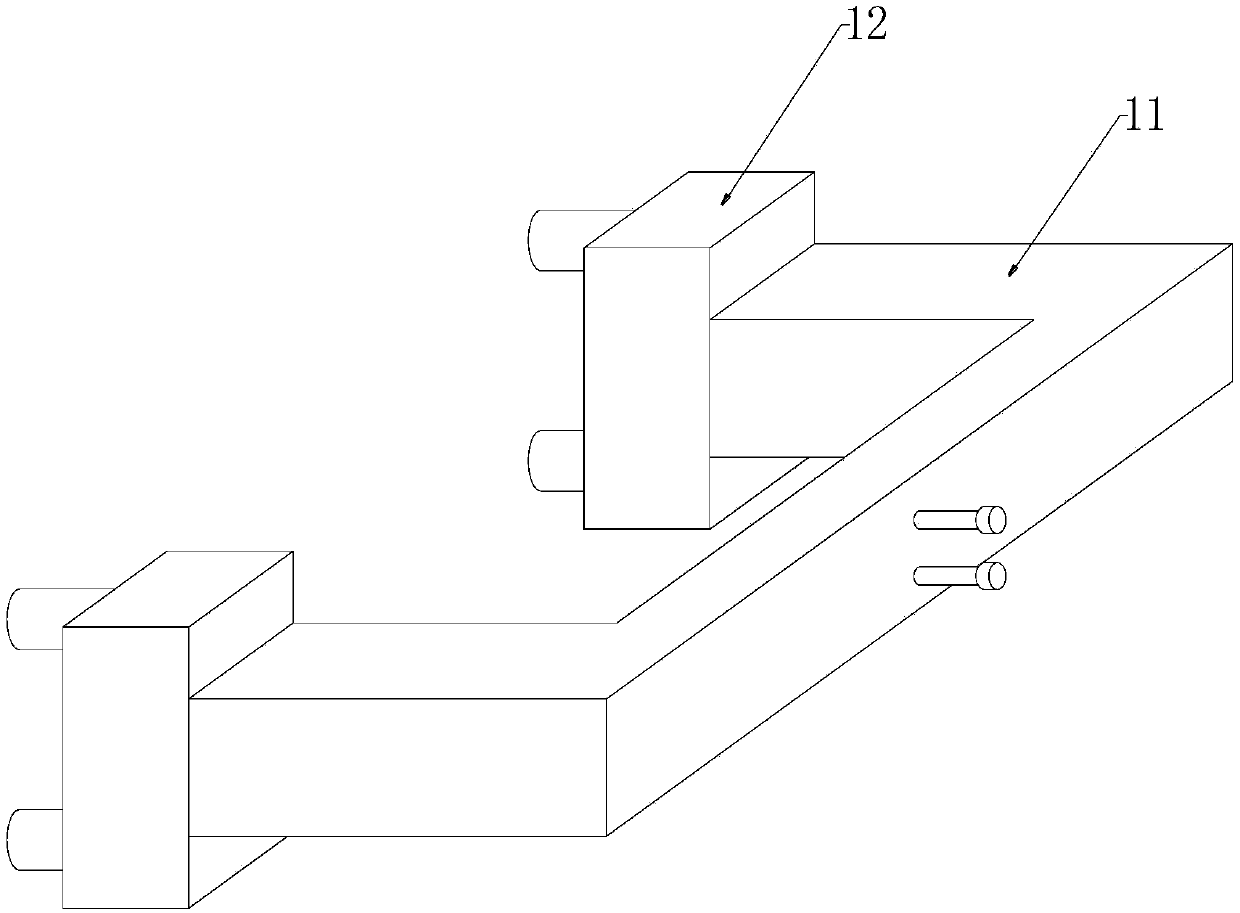

[0026] Such as Figure 1-3 As shown, an electronic yarn tension meter for weaving includes a base 1, a tension sensor 9 and a wire clamp 12, the tension sensor 9 and the wire clamp 12 are located at the same height on the base 1, and the tension sensor 9 is fixed on the L-shaped rod 8, The L-shaped rod 8 is welded on the top of the support column 7, and the support column 7 is fixed on the base 1 by bolts. The base 1 is provided with a battery 2 inside, and the battery 2 is connected to the grid through a charging wire. There are two clamps 12, and the two clamps 12 are respectively located on both sides of the tension sensor 9, and the two clamps 12 are fixed on the two ends of the movable U-shaped bar 11, and the U-shaped bar 11 is fixed on the top of the movable column 10 by bolts. The support column 7 is located below the tension sensor 9 and is provided with a fixed fixture 14. A force sensor 13 is provided between the fixed fixture 14 and the support column 7. The movabl...

Embodiment 2

[0030] Such as figure 1 As shown, the bottom of the movable column 10 is fixedly connected with the slider 4 by bolting or welding, the slider 4 is slidably installed on the guide rail 3, the guide rail 3 is integrally formed on the upper surface of the base 1 along the length direction of the base 1, and the slider 4 One end away from the support column 7 is fixed on the end of the telescopic rod of the cylinder 5 by screws, and the cylinder 5 is fixed on the end of the base 1 away from the support column 7 by a mounting block, and the telescopic rod of the cylinder 5 is parallel to the guide rail 3, and the cylinder 5 has control buttons.

[0031] By adopting the above technical solution, during the telescopic movement of the cylinder 5 , since the slider 4 is clamped on the guide rail 3 , it can guide the movement of the movable column 10 .

Embodiment 3

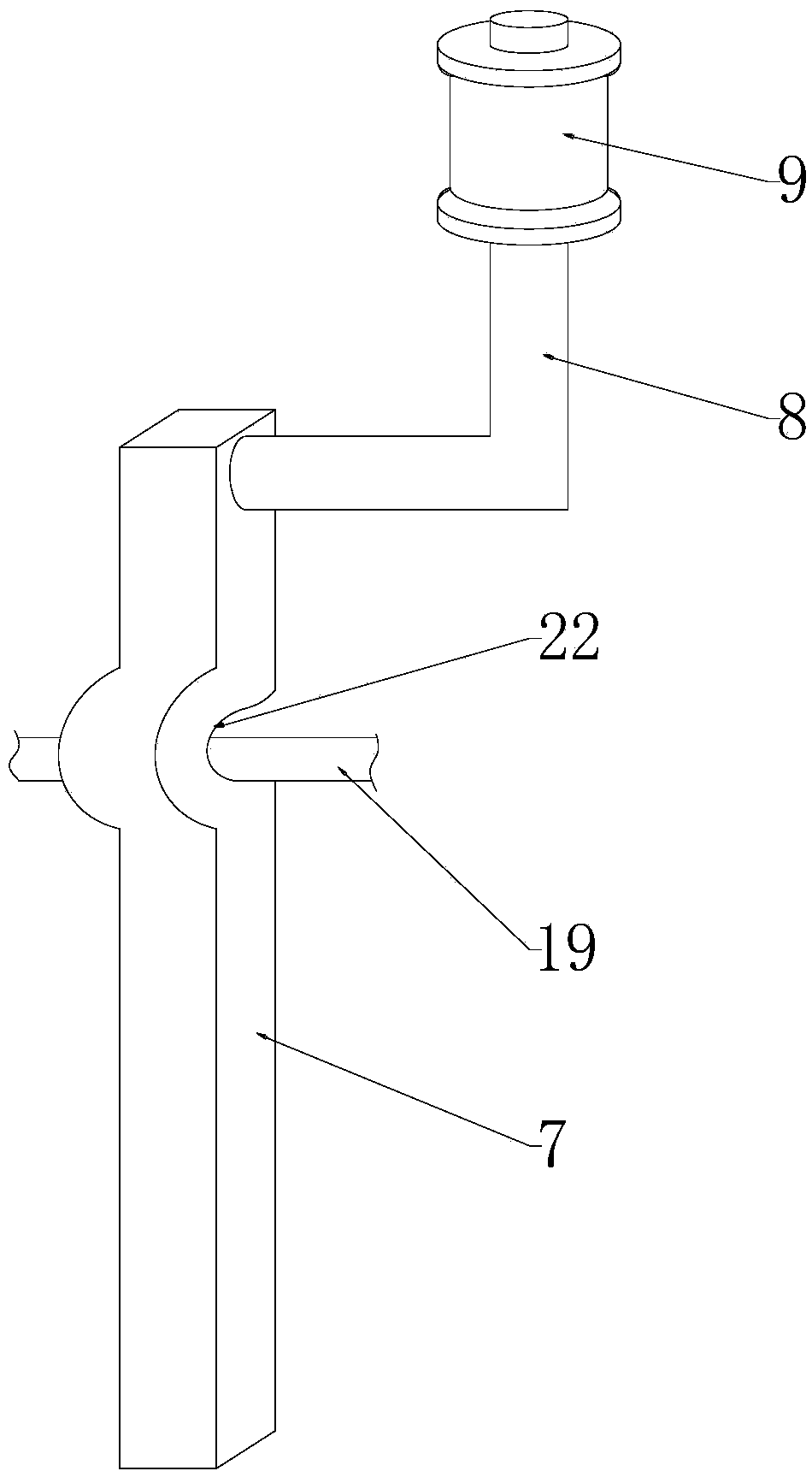

[0033] Such as figure 1 As shown, a nozzle 18 is arranged above the fixed fixture 14, and the nozzle 18 is installed at the end of the water spray pipe 19, and the water spray pipe 19 communicates with the water pump 21, and the water pump 21 is installed inside the water storage tank 20 through bolts, and the water storage tank 20 is fixed on the base 1, the water pump 21 is connected to the battery 2 through wires.

[0034] Such as Figure 4 As shown, an infrared heating lamp 17 is arranged above the movable fixture 15, and the infrared heating lamp 17 is installed at the end of the fixed rod 16, and the other end of the fixed rod 16 is welded to both ends of the fixed plate 23, and the fixed plate 23 is vertically fixed on the movable column 10 by bolts , The movable column 10 is provided with a control switch of an infrared heating lamp 17, and the infrared heating lamp 17 is connected with the storage battery 2 through a wire.

[0035] Such as image 3 As shown, the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com