Grating ruler calibration method and device and visual detection device

A grating ruler and coordinate technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of inconvenient operation and inaccurate calibration accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

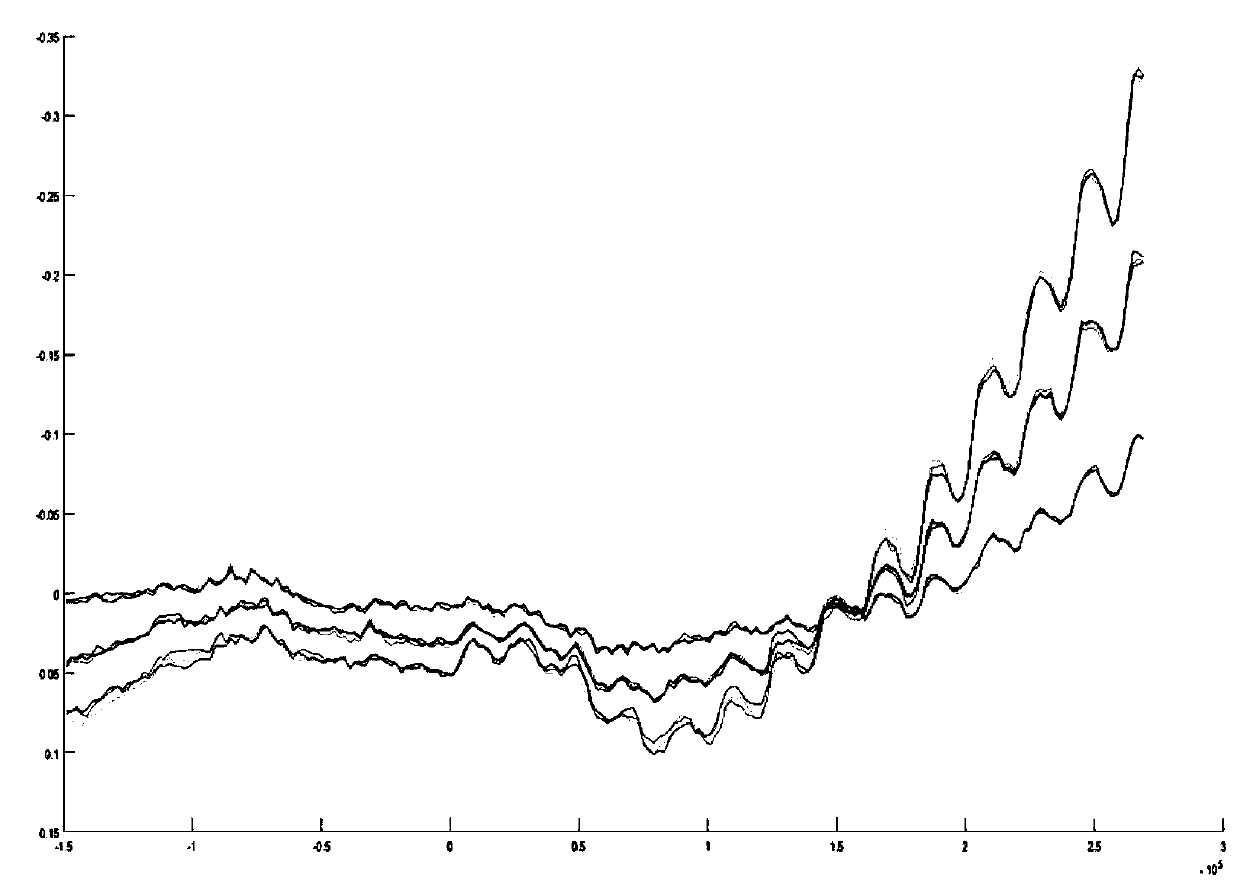

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0037] An embodiment of the present invention provides a grating ruler calibration method, including the following steps:

[0038] (1) Take a picture of the calibration board placed on the machine table, and the calibration board is used as a reference board for subsequent picture collection and calculation, and is covered on the loading table of the machine table. Such as figure 1 As shown in , the calibration plate is provided with a plurality of horizontal sampling areas 1 extending along the X-axis direction and located at different Y-axis positions and a plurality of longitudinal sampling areas 2 extending along the Y-axis direction and located at different X-axis positions, The horizontal sampling area 1 and the vertical sampling area 2 extend in a strip shape. Two or more horizontal sampling areas 1 and vertical sampling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com