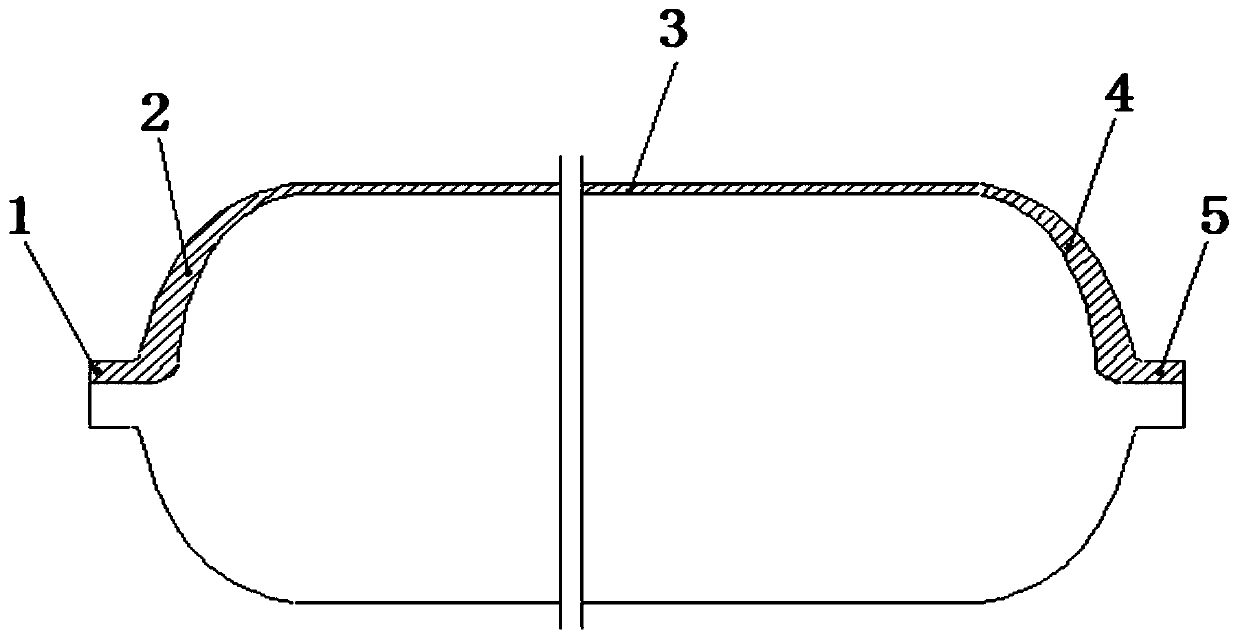

Ultra-high pressure gas cylinder liner with end caps and manufacturing method thereof

A manufacturing method and technology of compressed gas cylinders, applied in the field of high-pressure containers, can solve the problems of small volume, heavy quality, and poor reliability of ultra-high pressure gas cylinders, and achieve the effects of strict surface quality control, low pollution, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

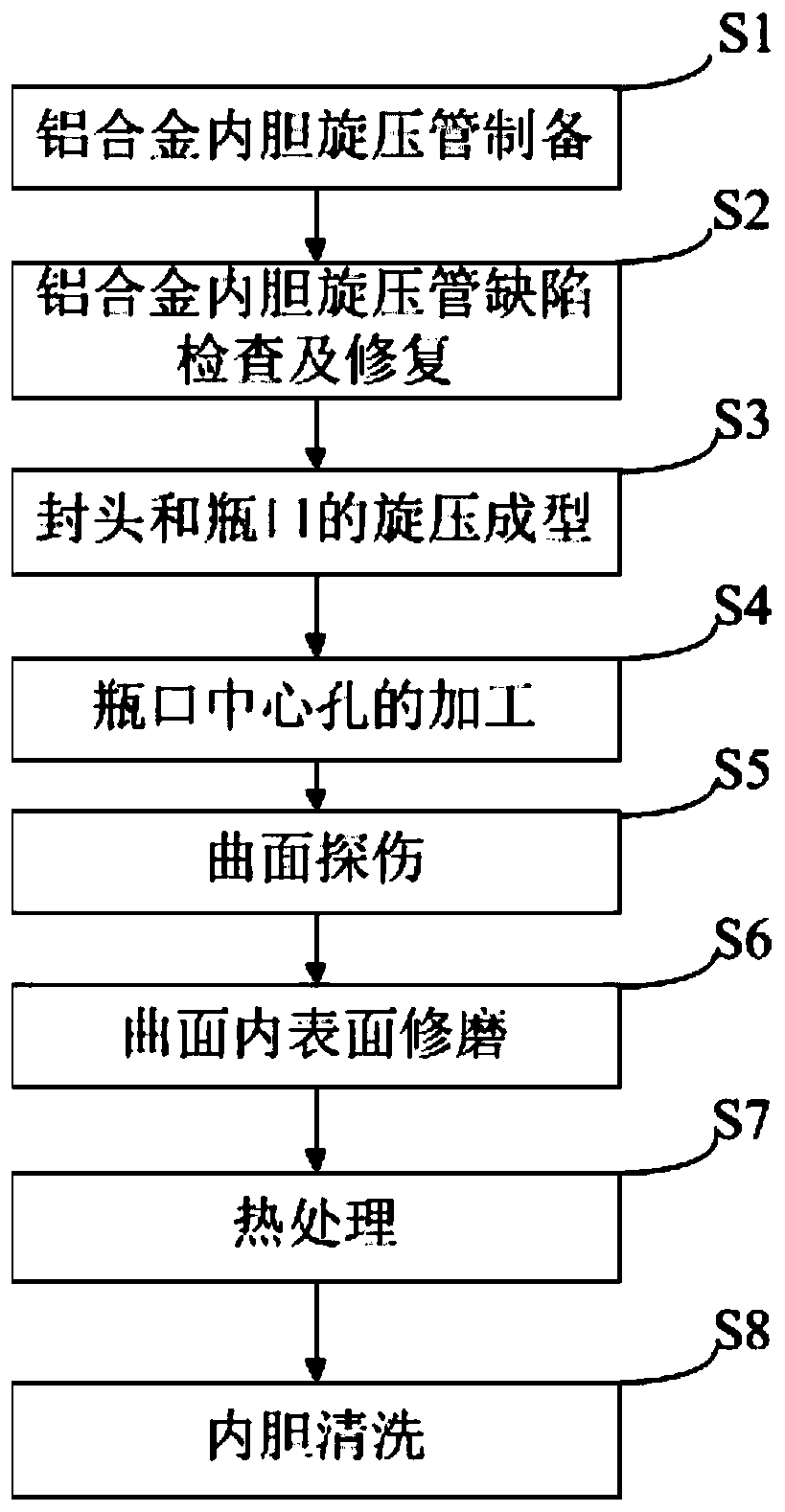

[0113] Prepare a super-high-pressure gas cylinder liner with a diameter of 500mm, a length of 3.5m, and a wall thickness of 5mm. The rated pressure of the super-high-pressure gas cylinder is required to be 70Mpa, specifically including the following steps:

[0114] S1, the preparation of aluminum alloy liner spinning tube, this step specifically includes the following steps:

[0115] S1a, the spinning forming of the straight section 3 of the aluminum alloy liner spinning tube, the seamless pipe with a length of 1.2m is spun two times by using the three-wheel staggered forward spinning method, and the three-wheel staggered forward spin The stagger amount in the pressing method is set to 6mm; the spinning piece A is obtained, and the spinning piece A is a straight cylinder of equal thickness or a straight cylinder section 3 with outer ring end frames at both ends; the size of the spinning piece A is: total length is 3700mm, the thickness of the straight section 3 is 5mm, and the...

Embodiment 2

[0148] Prepare a kind of 650mm, length 4m, the ultra-high pressure gas cylinder liner that wall thickness is 6mm with both ends of head, and its ultra-high pressure gas cylinder rated pressure requirement is 50Mpa, specifically comprises the following operation steps:

[0149] S1, the preparation of aluminum alloy liner spinning tube, this step specifically includes the following steps:

[0150] S1a, the spinning forming of the straight section 3 of the aluminum alloy liner spinning tube, the seamless pipe with a length of 1.5m is 2 times spinning by the three-wheel staggered reverse-spinning method, and the three-wheel staggered reverse spin The misalignment in the pressing method is set to 6mm;

[0151] The spinning part A is obtained, and the spinning part A is a straight tube of equal thickness or a straight tube section 3 with an outer circumferential end frame at both ends; the size of the spinning part A is: the total length is 4200mm, and the thickness of the straight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Circularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com