Eddy current machine nickel-iron alloy magnetic conductive plate and manufacturing method thereof

A production method and ferroalloy technology, applied in the field of powder metallurgy of metal materials, can solve the problems of increasing the ampere-turns of electric coils, increasing material costs, and small braking torques, so as to reduce the ampere-turns of coils, reduce production costs, and lead good magnetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

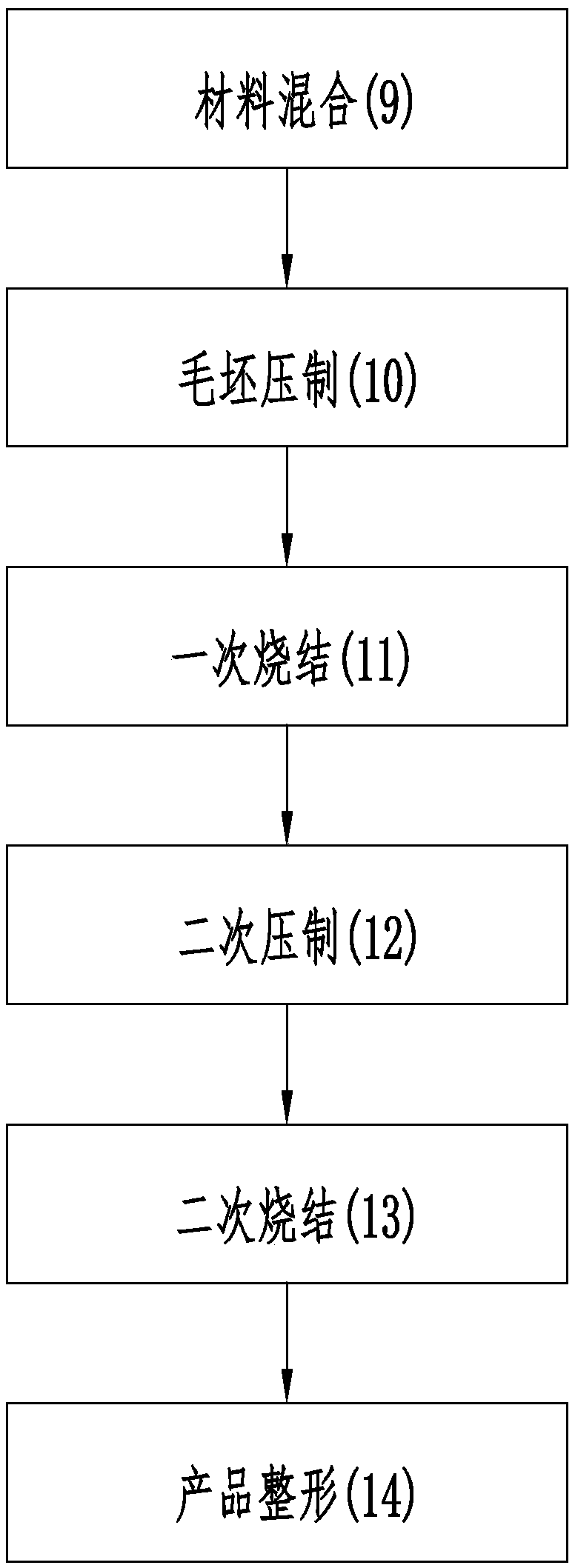

[0042] Step 1. Mix 4.9% carbonyl nickel powder, 0.6% microwax powder, 0.4% manganese sulfide and 94.1% pure iron powder in proportion by weight, wherein carbonyl nickel powder is selected from 200 mesh carbonyl nickel powder, and pure iron powder is selected from 100 mesh Water atomized pure iron powder.

[0043] Step 2. Put the mixed raw materials into the blank mold cavity, press 6.3 g / cm 3 The density is pressed to make a blank.

[0044] Step 3: The blank is sintered for the first time at a temperature of 1050° C. under a protective atmosphere mixed with nitrogen and hydrogen to obtain a product.

[0045] Step 4. After the first sintering is completed, the product is pressed at 7.46 g / cm 3 The density is double-compressed to make the product have a higher material density.

[0046] Step 5, the product is sintered for the second time at a temperature of 1180° C. under a mixed protective atmosphere of nitrogen and hydrogen.

[0047] Step 6: After the second sintering is c...

Embodiment 2

[0050]Step 1. Mix 5% carbonyl nickel powder, 0.5% microwax powder, 0.5% manganese sulfide and 94% pure iron powder in proportion by weight, wherein carbonyl nickel powder is selected from 200 mesh carbonyl nickel powder, and pure iron powder is selected from 100 mesh Water atomized pure iron powder.

[0051] Step 2: Put the mixed raw materials into the blank mold cavity, press 6.2 g / cm 3 The density is pressed to make a blank.

[0052] Step 3: The blank is sintered for the first time at a temperature of 1050° C. under a protective atmosphere mixed with nitrogen and hydrogen to obtain a product.

[0053] Step 4. After the first sintering is completed, the product is pressed at 7.42 g / cm 3 The density is double-compressed to make the product have a higher material density.

[0054] Step 5, the product is sintered for the second time at a temperature of 1180° C. under a mixed protective atmosphere of nitrogen and hydrogen.

[0055] Step 6: After the second sintering is comple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com