Waste organic solvent recycling device

A technology of organic solvents and solvents, which is applied in the field of waste organic solvent recovery and reuse devices, can solve the problems of low utilization rate of waste organic solvents and high operating costs, and achieve the effects of safe heating, reduced operating costs, and convenient distillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

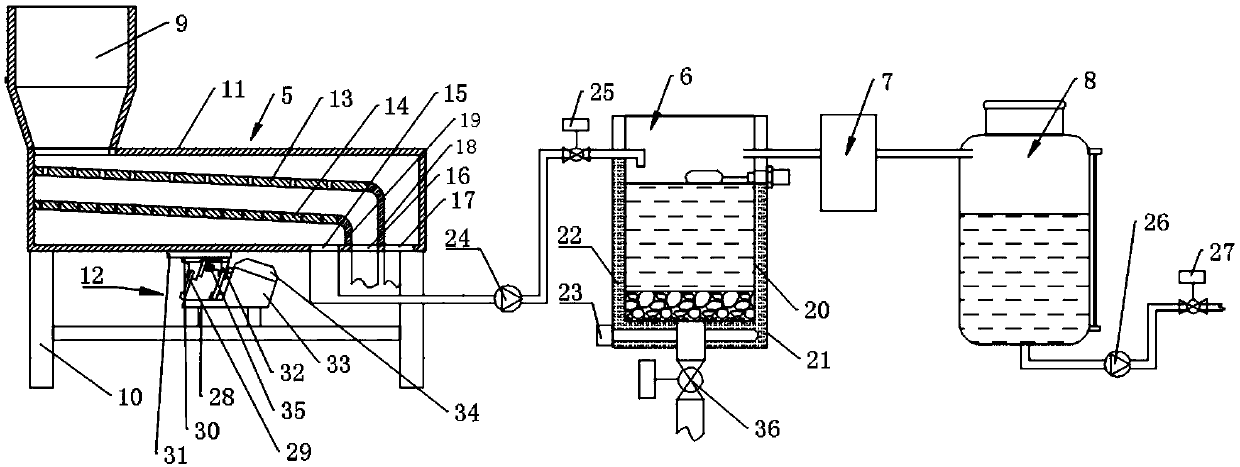

[0029] Such as figure 1 As shown, a waste organic solvent recovery and reuse device includes a solvent recovery machine 1, a pressurized atomization device 2, a power system 3 and RTO4, and the solvent outlet end of the solvent recovery machine 1 is connected to the pressurized atomizer The device 2 communicates, and the pressurized atomizing device 2 communicates with the combustion chamber of the RTO4 through the power system 3 .

[0030] The solvent recovery machine 1 can adopt the intelligent numerical control explosion-proof solvent recovery machine 1 in the prior art, such as the J20Ex-A type solvent recovery machine; the pressurized atomization device 2 can adopt the compression atomization pump in the prior art; the power system 3 can be Adopt the blower fan in the prior art. RTO4 is the abbreviation of regenerative thermal incinerator. When the power system 3 is a fan, the atomized regenerated solvent is directly blown or sucked into the combustion chamber of RTO4 t...

Embodiment 2

[0034] Such as figure 2As shown, the present embodiment is based on Example 1, and the solvent recovery machine 1 includes a filter device 5, a distillation tank 6, a condenser 7 and a vacuum decompression pump 8, and the filter device 5 includes a feed hopper 9, Frame 10, cabinet 11 and vibrating mechanism 12, described cabinet 11 is installed above described frame 10, and described vibrating mechanism 12 is installed between described frame 10 and cabinet 11; Described feed hopper 9 is installed on The top of the cabinet 11, the outlet of the feed hopper 9 communicates with the top of the cabinet 11, the cabinet 11 is sequentially installed with a first vibrating screen 13 and a second vibrating screen 14, The first vibrating screen 13 is arranged obliquely downward from left to right, the second vibrating screen 14 is arranged parallel to the first vibrating screen 13, and the bottom of the cabinet 11 is sequentially provided with a liquid outlet 15, The first slag outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com