Special steel wire rope winding drum device

A wire rope reel and reel technology, which is applied in the field of wire ropes, can solve the problems of wire rope movement, affecting the lifting operation of the crane, and the wire rope falling off, so as to achieve the effect of avoiding excessive winding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

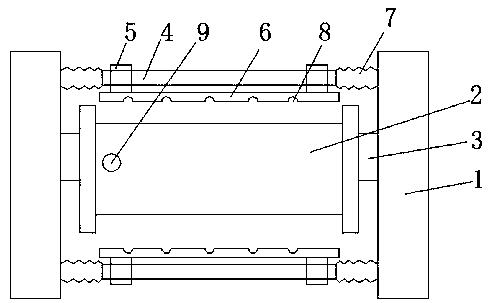

[0013] Such as figure 1 As mentioned above, a special wire rope reel device of the present invention includes a bracket 1, a reel 2 is arranged inside the bracket 1, and both sides of the reel 2 are connected to the bracket 1 through a connecting shaft 3, and the reel 2 The upper and lower sides are symmetrically provided with an anti-off device, the anti-off device includes a fixed bracket 4 connected to the bracket 1, the inner side of the fixed bracket 4 is connected to the anti-off ring 6 through the connecting ring 5, and the two ends of the fixed bracket 4 It is the elastic bracket 7 connected with the bracket 1.

[0014] A semicircular hole 8 corresponding to the wire rope is provided inside the anti-falling ring 6 .

[0015] The reel 2 is provided with embedded holes 9 .

[0016] In the above technical solution, compared with the prior art, the beneficial effect achieved is: through the positioning of the embedded hole 9, the steel wire rope can be avoided from jumpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com