Detecting method for disengagement of steel wire rope from groove and detecting device

A detection device and detection method technology, applied in the direction of winding device, spring mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

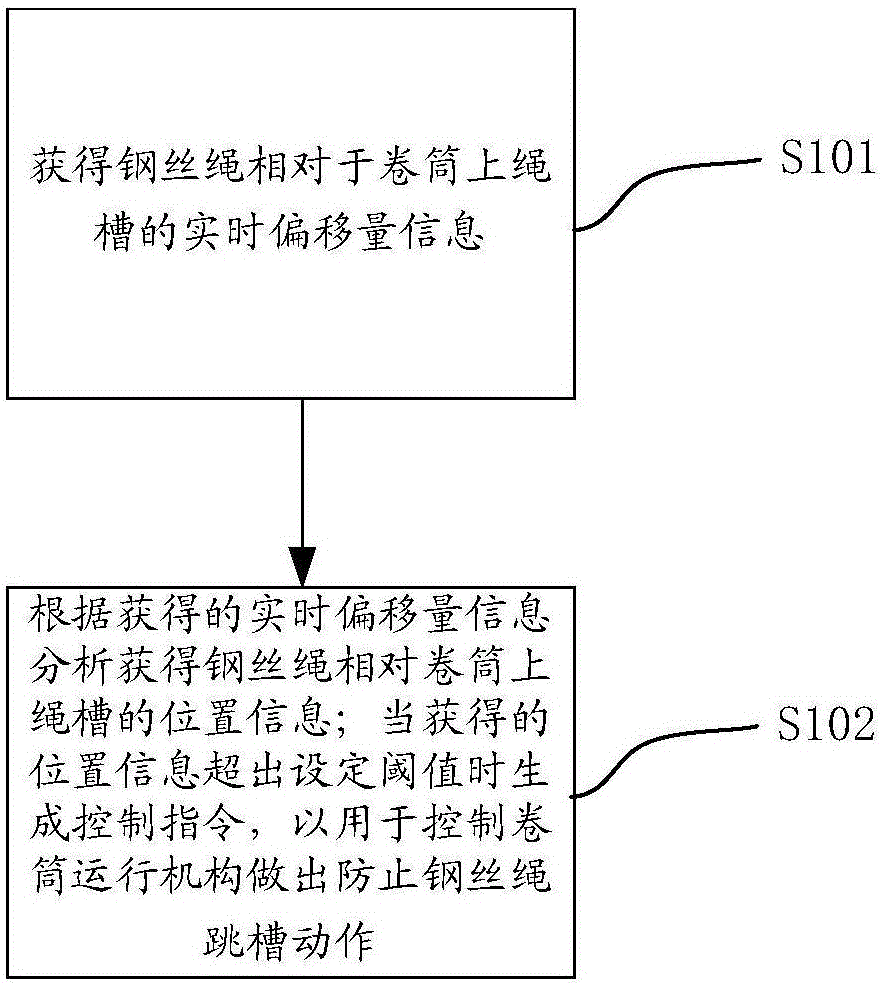

[0035] figure 1 The flowchart of the steel wire rope job-hopping detection method provided by the embodiment of the present invention, such as figure 1 As shown, the steel wire rope slot detection method provided by the embodiment of the present invention includes:

[0036] Step S101, obtaining real-time offset information of the wire rope relative to the rope groove 11 on the drum 1;

[0037] Step S102, analyzing and obtaining the position information of the steel wire rope relative to the rope groove 11 on the reel 1 according to the obtained real-time offset information; when the obtained position information exceeds the set threshold, a control command is generated to control the reel operating mechanism to make Prevent the wire rope from jumping.

[0038] Using the method provided by the present invention to detect the offset of the wire rope, at first, in step S101, obtain the real-time offset information of the wire rope relative to the rope groove 11 on the reel 1, t...

Embodiment 2

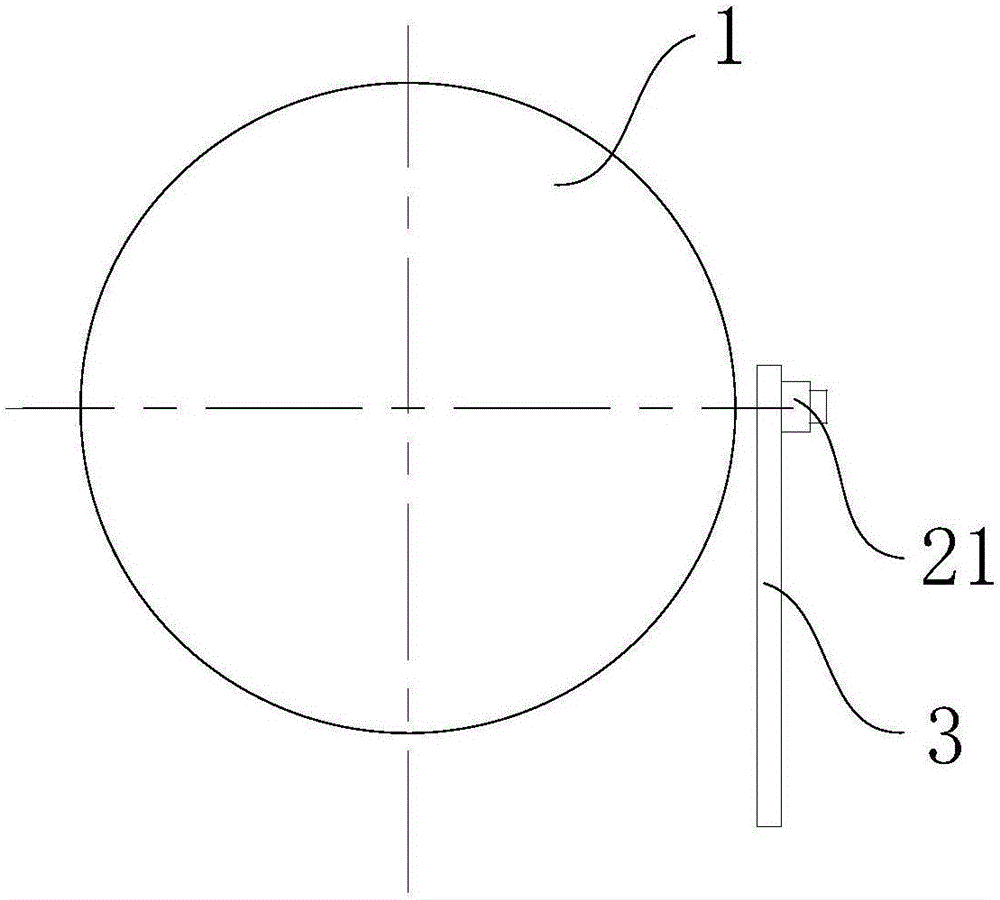

[0041] The purpose of this embodiment is to provide a detection device to solve the technical problem of the steel wire rope skipping existing in the prior art.

[0042] The detection device provided in this embodiment is used to implement the method provided in the first embodiment above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com