Mine hoisting steel wire rope abrasion area and steel wire rope safety coefficient prediction method

A technology of safety factor and prediction method, applied in the field of mine hoisting wire rope wear area and safety factor prediction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

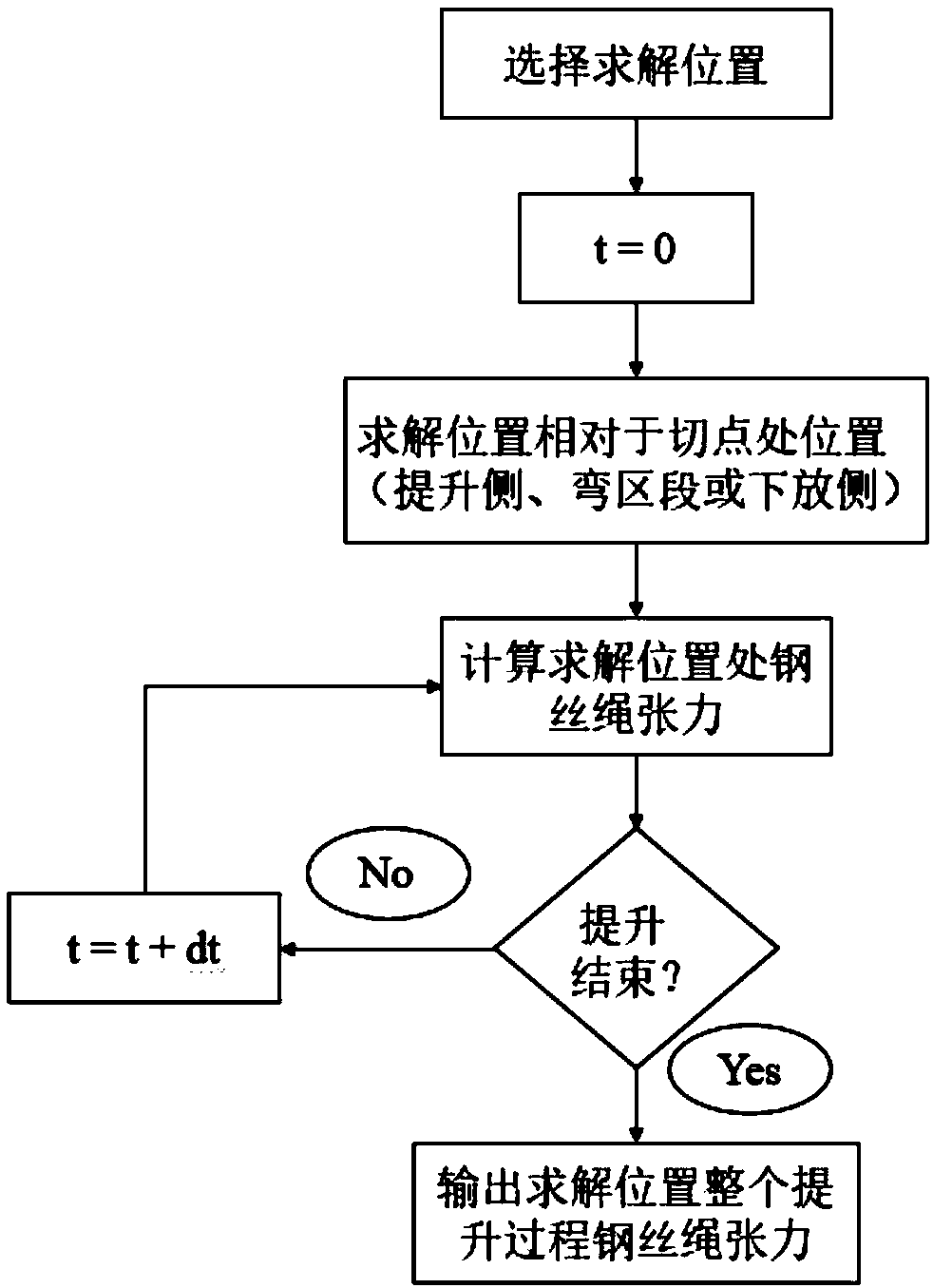

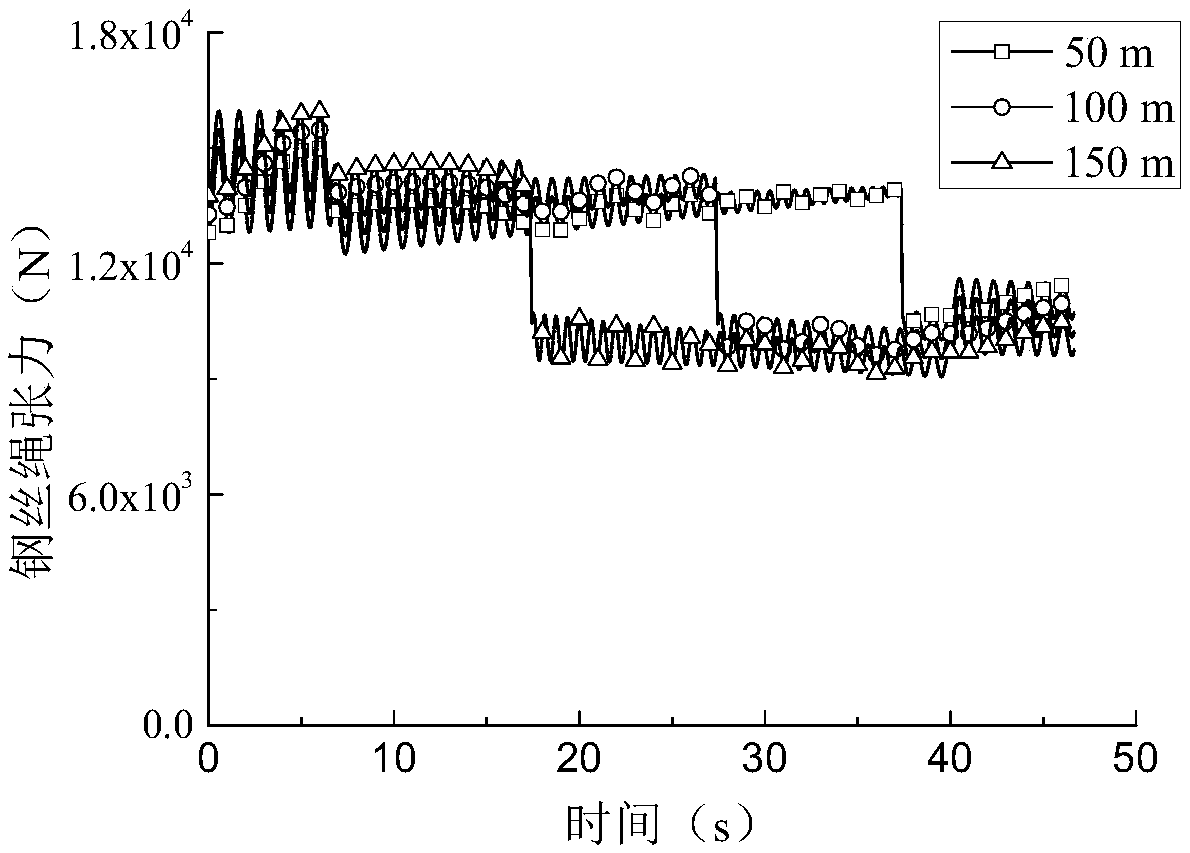

[0105] First, according to figure 1 The flow chart for calculating the dynamic tension of the steel wire rope is shown, and the parameters of the hoisting system (elastic modulus of the steel wire rope, total cross-sectional area of the steel wire, terminal mass, acceleration of gravity, hoisting acceleration, wire rope mass, hoisting speed, etc.) are substituted into the formulas (1)-(3) , to obtain figure 2 The dynamic tension of the wire rope at different positions is shown.

[0106]

[0107]

[0108] S 1x(2x) = S 1(2) -ρ·x·g formula (3)

[0109] After obtaining the dynamic tension of the steel wire rope at any position, the dynamic tension can be substituted into formulas (4)-(6), and the tension of each steel wire, the tension of each strand and the elongation of each steel wire can be obtained respectively.

[0110]

[0111]

[0112]

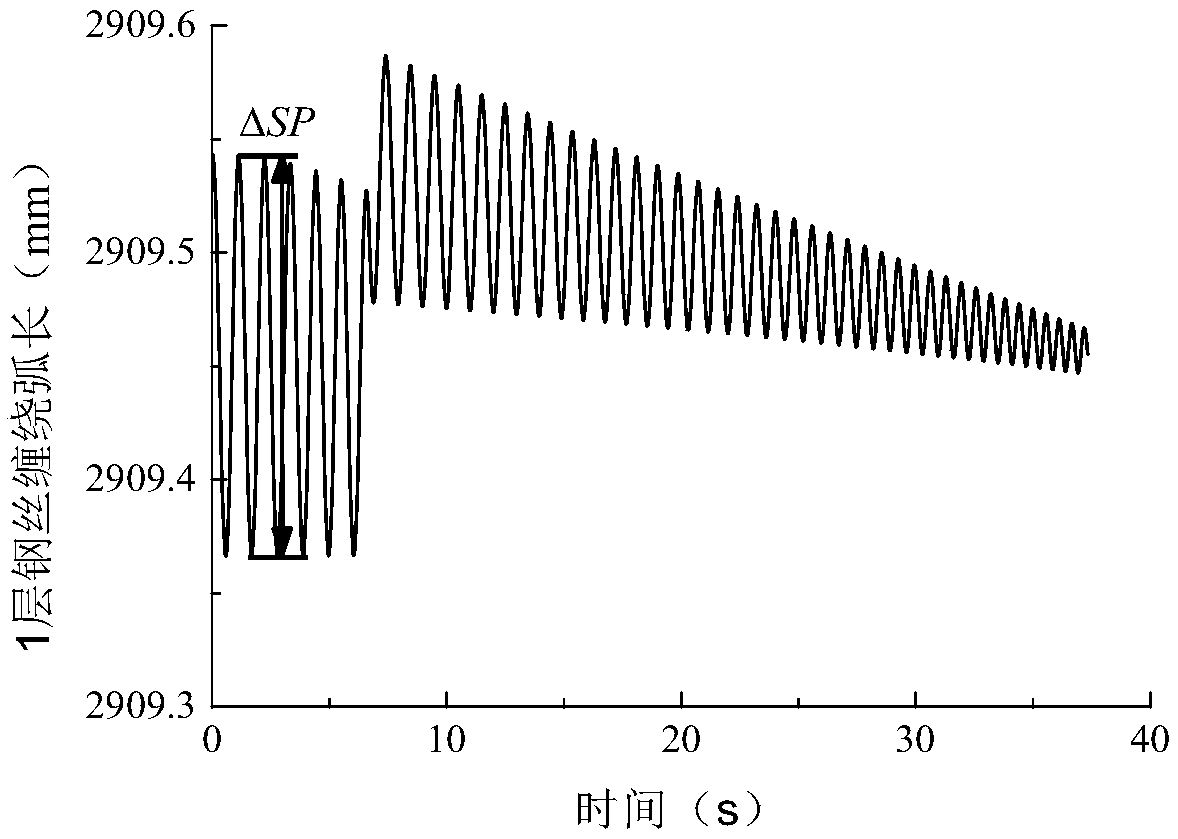

[0113] According to the elongation of steel wire, it can be obtained image 3 The winding arc length of the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com