Novel belt tensioning device of forearm frame of bucket-wheel stacker reclaimer

A bucket-wheel stacker-reclaimer and tensioning device technology, applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of increasing load, increasing the manufacturing cost of bucket-wheel stacker-reclaimer, wasting output power, etc. , to achieve the effect of light weight, improving the problem of belt deviation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Provide the realization process of the patent of the present invention below in conjunction with accompanying drawing and concrete implementation.

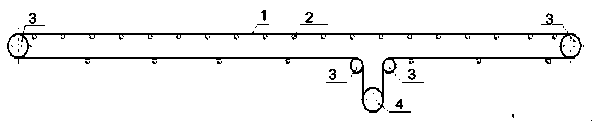

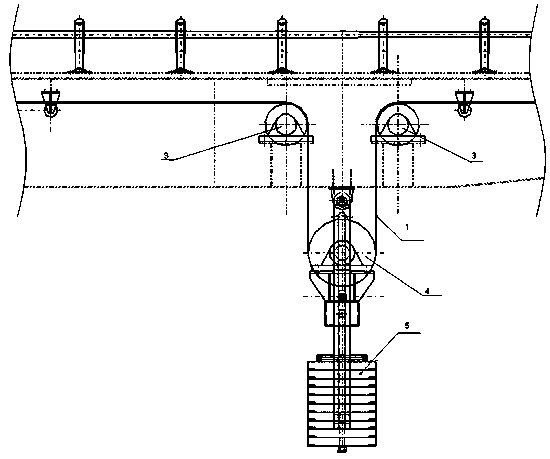

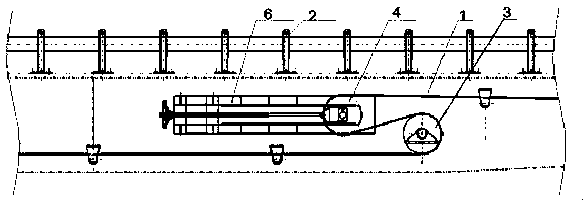

[0027] A new belt tensioning device for the front arm frame of a bucket-wheel stacker-reclaimer, including a tensioning roller (4), a redirecting roller (3) and a screw tensioning device (6), wherein the screw tensioning device (6 ) consists of a support frame (9), a handwheel (7), a screw rod (8), and a tensioning roller (4). The support frame (9) is used to fix the tensioning roller (4) and is installed on the left side of the front arm 1. On the outside of the right web, the left and right webs have an elongated round hole, the shaft of the tensioning roller (4) passes through the elongated round hole and is connected with the support frame (9), and one end of the screw rod (8) is connected with the The tensioning roller (4) is connected, and the other end of the screw is connected with the hand wheel (7). The upper and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com