Automobile bottom guard plate of LFT plate and production method thereof

A sheet and automobile technology, applied in the field of automobile bottom guard and its production, can solve the problems of damaged automobile parts, LFT sheet processing punching, deformation, etc., to achieve the effect of strong pressure, avoid rigid contact, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

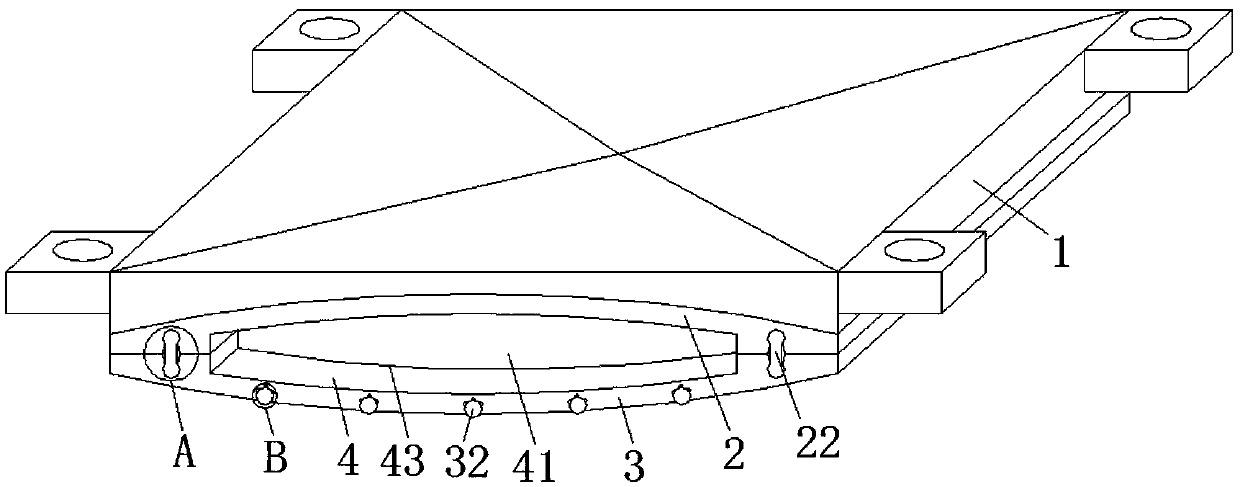

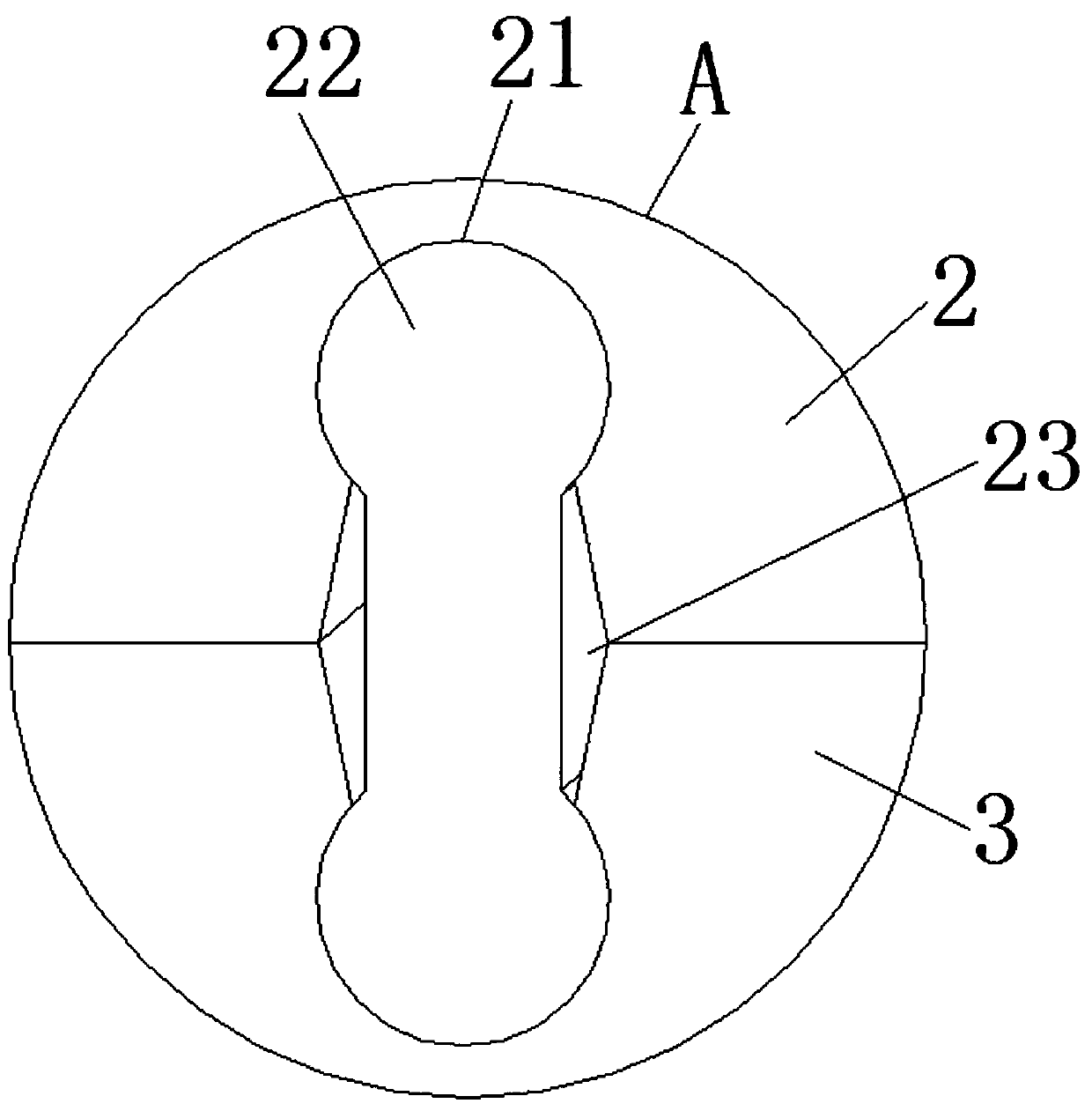

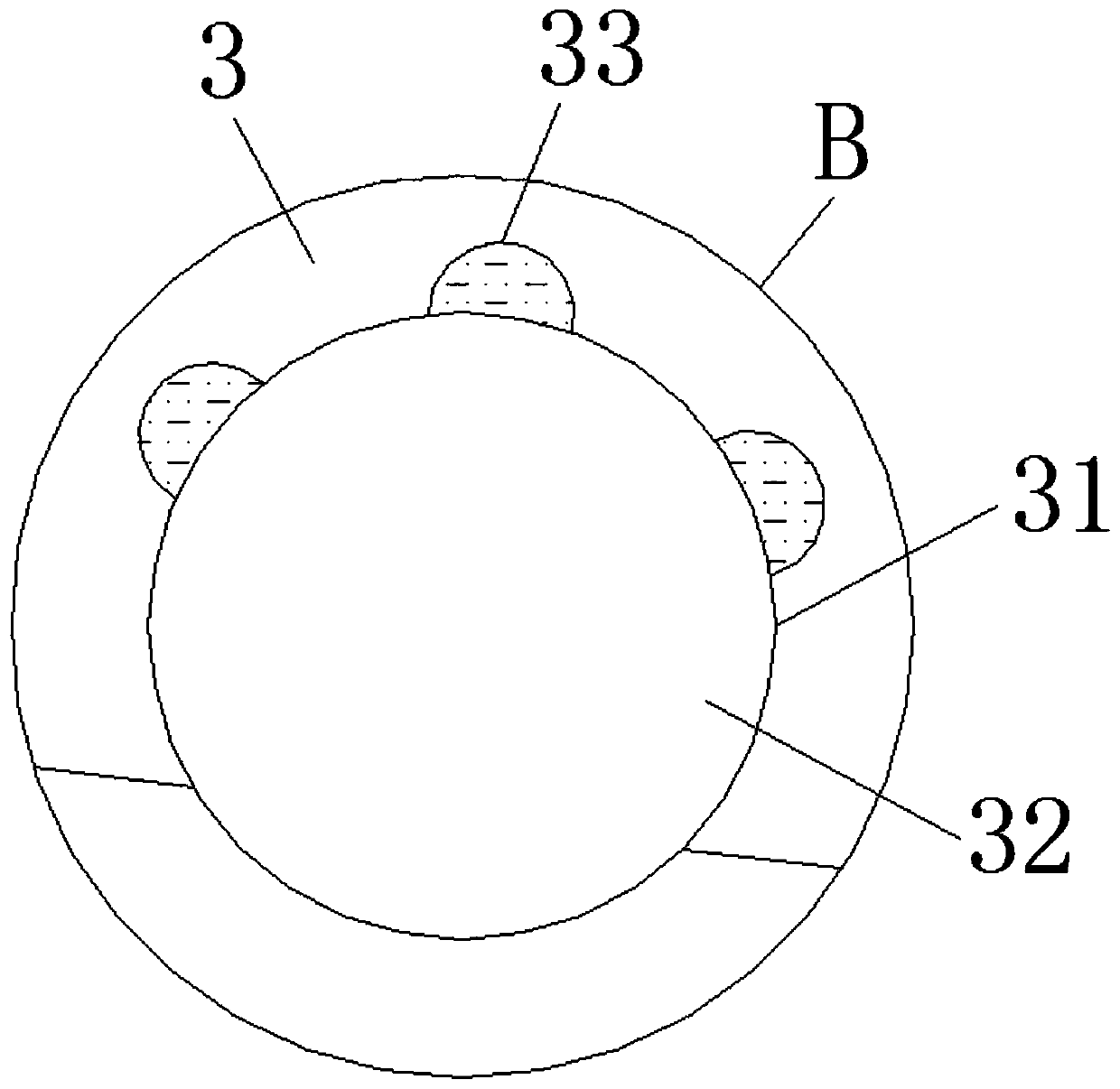

[0045] refer to Figure 1-8 , a kind of LFT plate automobile underbody guard plate and production method thereof, such as figure 1 As shown, including the installation substrate 1, the upper surface of the installation substrate 1 is concave, and the inner wall of the concave shape is in the shape of a quadrangular pyramid. The four corners of the installation substrate 1 are fixedly installed with fixed connectors, and the lower surface of the installation substrate 1 is fixedly welded. There is an upper guard plate 2, and a lower guard plate 3 is arranged on the lower surface of the upper guard plate 2.

[0046] The manufacturing method of the lower guard plate 3 is as follows: the manufacturing material of the lower guard plate includes LFT plate and buffer rubber, the inner surface of S1 and the LFT plate and the buffer rubber are fixed and bonded by rubber adhesive, and the composition of the buffer rubber includes 50% natural rubber, 10% added rubber, 5% diene elastic f...

Embodiment 2

[0058] refer to Figure 1-8 , a kind of LFT plate automobile underbody guard plate and production method thereof, such as figure 1As shown, including the installation substrate 1, the upper surface of the installation substrate 1 is concave, and the inner wall of the concave shape is in the shape of a quadrangular pyramid. The four corners of the installation substrate 1 are fixedly installed with fixed connectors, and the lower surface of the installation substrate 1 is fixedly welded. There is an upper guard plate 2, and a lower guard plate 3 is arranged on the lower surface of the upper guard plate 2.

[0059] The manufacturing method of the lower guard plate 3 is as follows: the manufacturing material of the lower guard plate includes LFT plate and buffer rubber, the inner surface of S1 and the LFT plate and the buffer rubber are fixed and bonded by rubber adhesive, and the composition of the buffer rubber includes 50% natural rubber, 13% added rubber, 7% diene elastic fi...

Embodiment 3

[0071] refer to Figure 1-8 , a kind of LFT plate automobile underbody guard plate and production method thereof, such as figure 1 As shown, including the installation substrate 1, the upper surface of the installation substrate 1 is concave, and the inner wall of the concave shape is in the shape of a quadrangular pyramid. The four corners of the installation substrate 1 are fixedly installed with fixed connectors, and the lower surface of the installation substrate 1 is fixedly welded. There is an upper guard plate 2, and a lower guard plate 3 is arranged on the lower surface of the upper guard plate 2.

[0072] The manufacturing method of the lower guard plate 3 is as follows: the manufacturing material of the lower guard plate includes LFT plate and buffer rubber, the inner surface of S1 and the LFT plate and the buffer rubber are fixed and bonded by rubber adhesive, and the composition of the buffer rubber includes 50% natural rubber, 15% added rubber, 8% diene elastic f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com