A plastic bottle injection molding machine

A technology for injection molding machines and plastic bottles, which is applied to household appliances, other household appliances, household components, etc. It can solve the problems of increasing the footprint of injection molding machines and reducing the space utilization efficiency of injection molding machines, so as to improve injection molding production efficiency and shorten the production time. length, the effect of reducing the slip distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

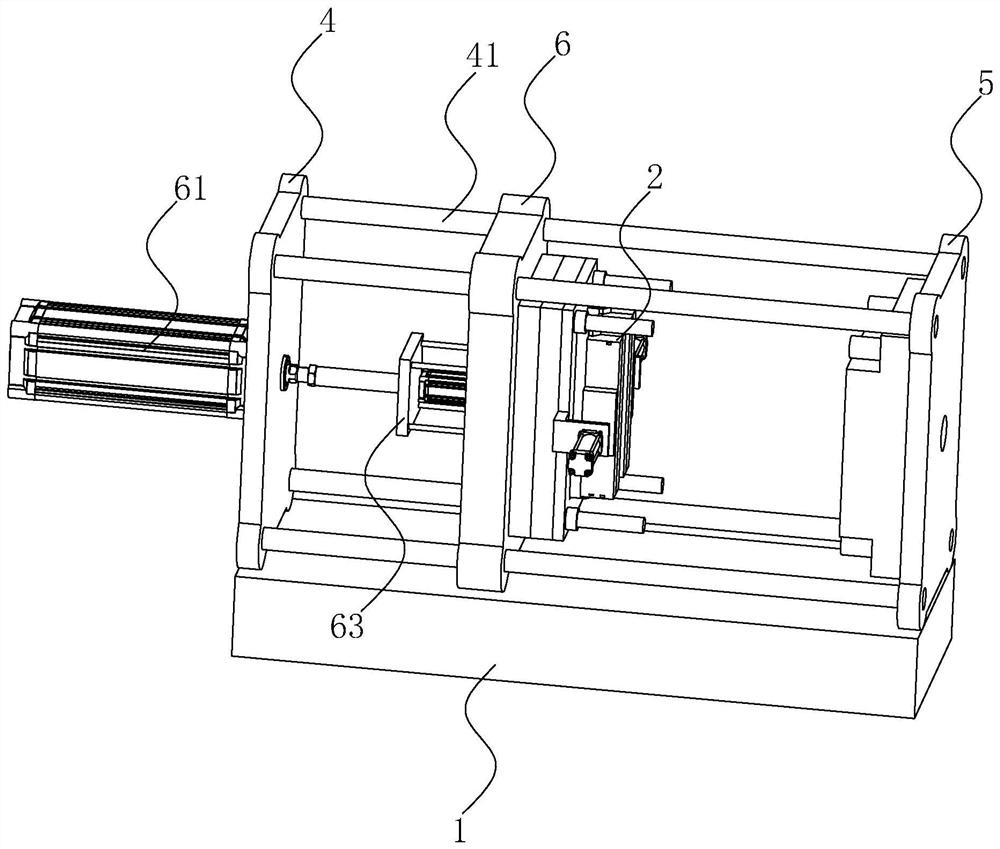

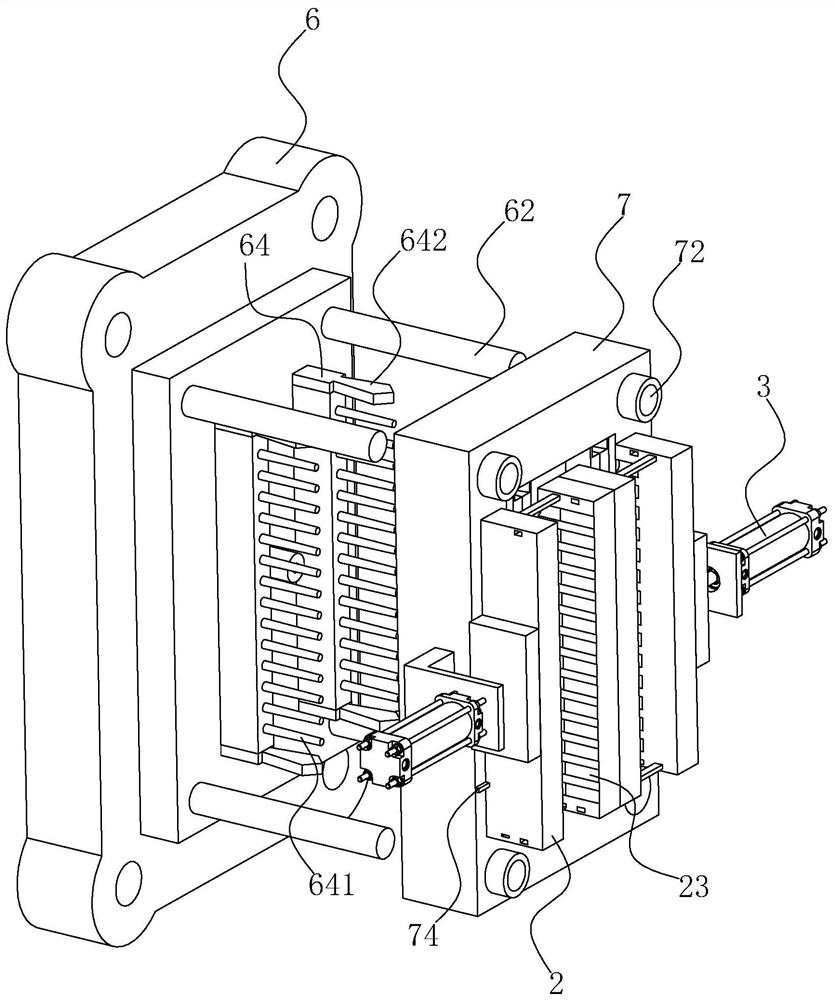

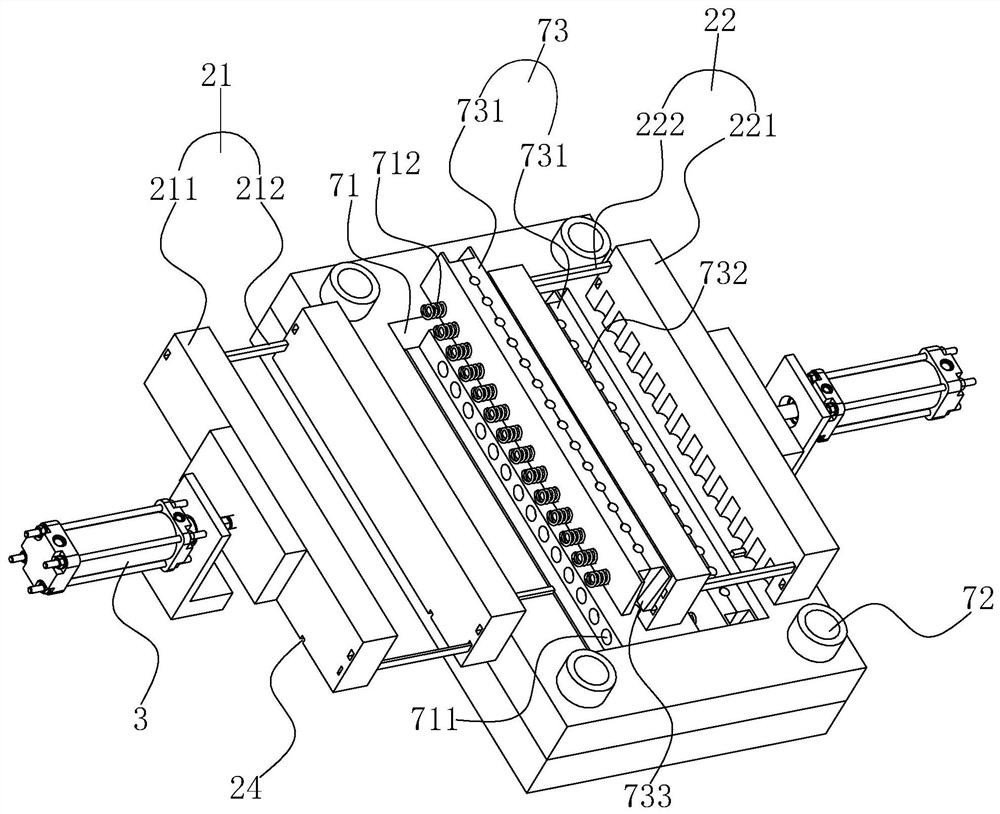

[0035] Embodiment, a kind of plastic bottle injection molding machine, as figure 1 As shown, it includes a machine 1, a forming mold 2 fixed on the machine 1, and a driving cylinder 3 for driving the forming mold 2 to open and close the mold. The forming mold 2 is connected with a number of injection pipes.

[0036] Such as figure 1As shown, the machine 1 is in the shape of a rectangular table, and the two ends of the machine 1 in the length direction are respectively vertically fixed with side plates 4 and detection plates 5 , both of which are in the shape of rectangular plates. Four sliding columns 41 are fixed horizontally between the side plate 4 and the detection plate 5 . The sliding columns 41 are cylindrical, and their two ends are respectively fixed at the four corners of the side plate 4 and the detection plate 5 . A seat plate 6 is slidably disposed on the sliding post 41 . The seat plate 6 is in the shape of a rectangular plate and the four sliding posts 41 are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com