A dual-machine self-synchronously driven balanced vibrating crusher

A crusher, self-synchronizing technology, applied in grain processing and other directions, can solve the problems of strict qualifications of installers and operators, complicated installation process, easy wear of jaw plates, etc., and achieves increased crushing stroke and compact mechanical structure. , the effect of small vertical stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

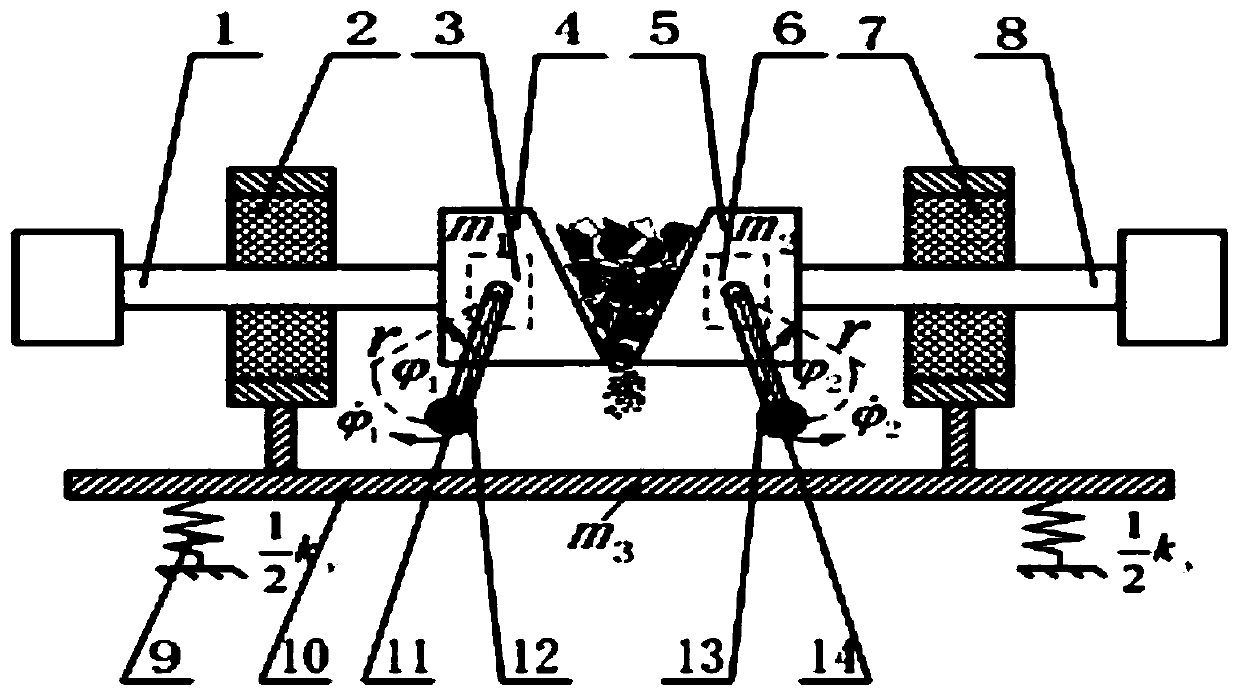

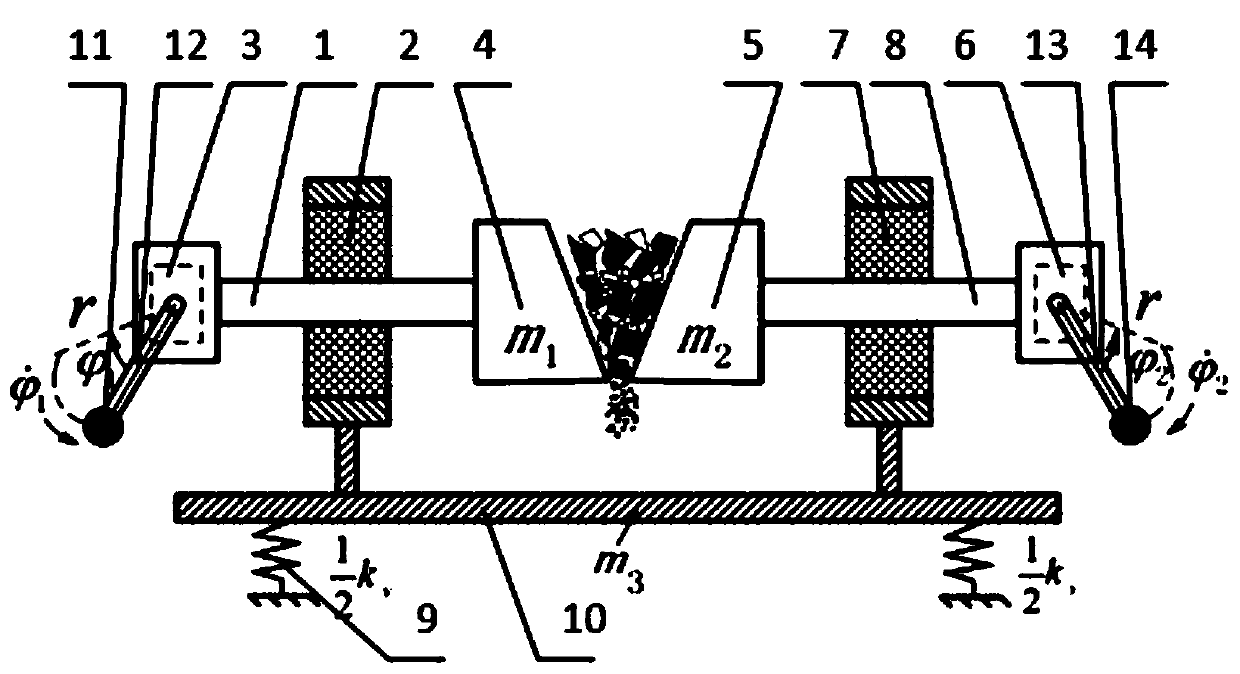

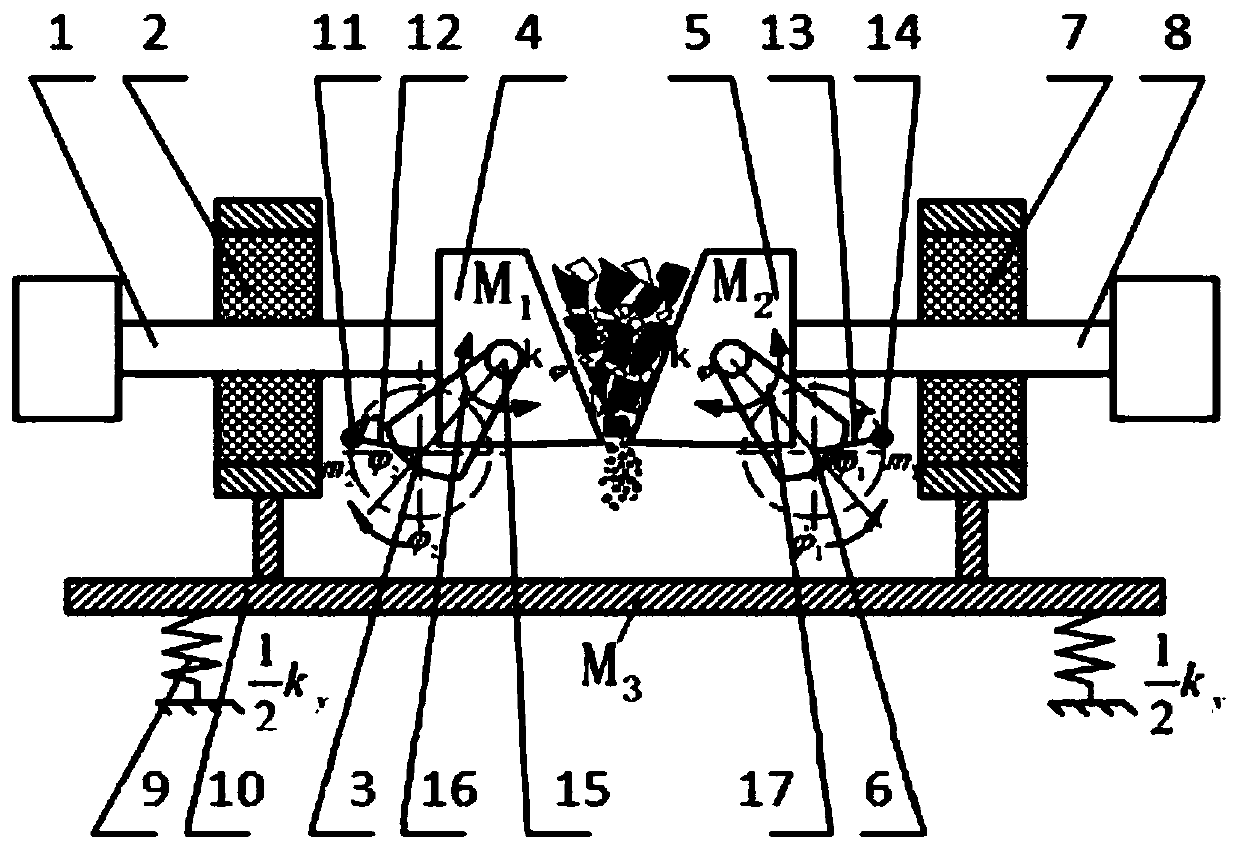

[0023] figure 1 Among them, the left vibrator 3 and the right vibrator 6 are a pair of symmetrically arranged vibrators, the left pendulum ball 11 and the left pendulum rod 12 are installed on the left vibrator 3, the right pendulum rod 13 and the right pendulum ball 14 Installed on the right vibrator 6, the left vibrator 3 is built into the left jaw plate 4, the left jaw plate 4 is connected with the left main vibration spring 2 through the left support body 1, and the right vibrator 6 is built into the right jaw plate 5, the right jaw plate 5 is connected with the right main vibration spring 7 through the right support body 8, and the two main vibration springs are respectively installed on both sides of the vibration isolation body 10, and the vibration isolation body 10 is connected to the foundation by the vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com