A kind of pretreatment production automatic linkage line of toxic medicinal materials and its processing method

A technology of medicinal materials and linkage, which is applied in the pre-treatment production automation linkage line of toxic medicinal materials and its processing field, can solve the problems of increasing production costs of enterprises, poor versatility, and needs to be improved, and achieve good versatility, good versatility, The effect of promoting the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

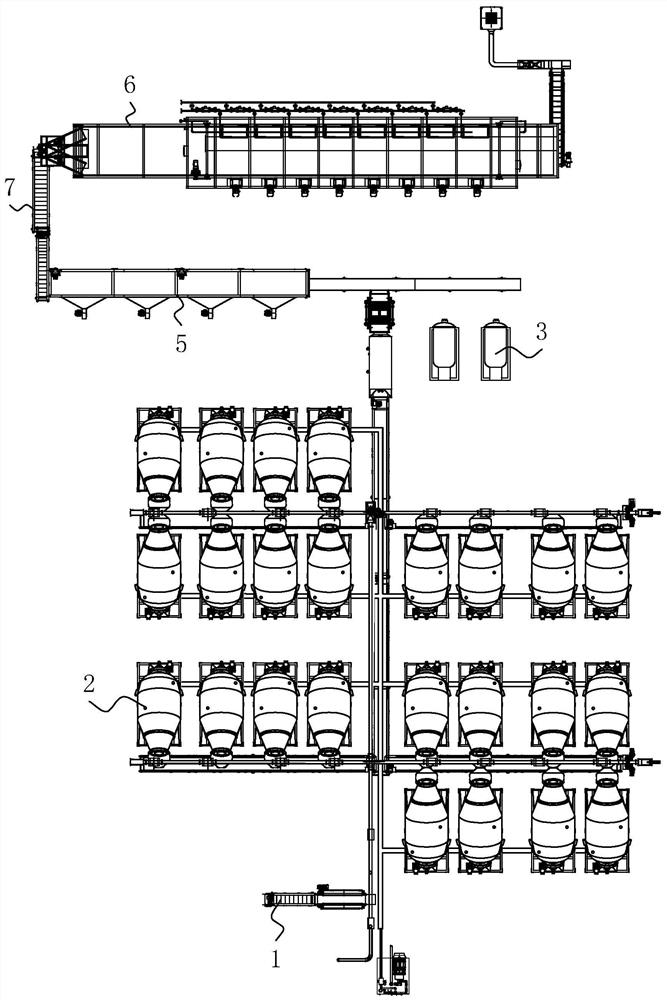

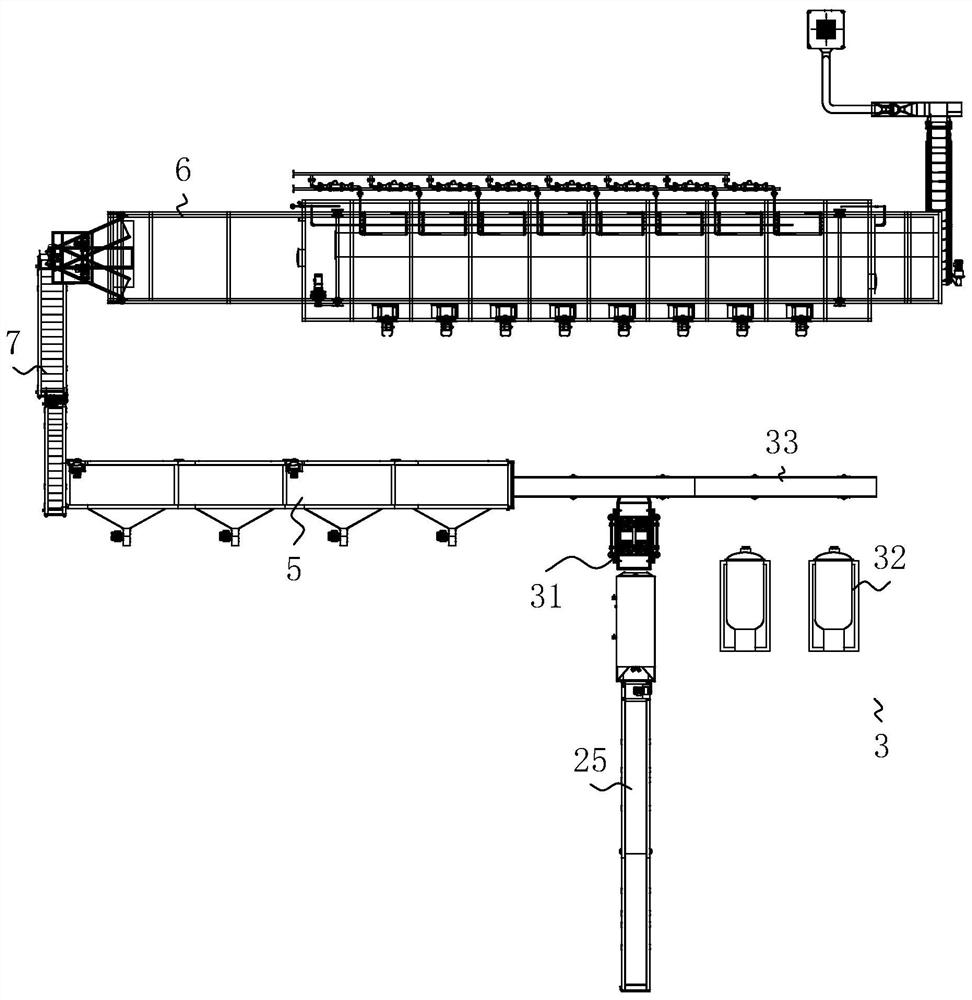

[0051] refer to figure 1 , is an automatic linkage line for the pretreatment production of toxic medicinal materials disclosed in the present invention, which sequentially includes a feeding unit 1, a soaking unit 2, a cooking unit 3, a mesh belt drying machine 5, and a belt drying machine 6 along the conveying direction. Wherein, the discharge port of the feeding unit 1 is located on the soaking unit 2, the discharge port of the soaking unit 2 is located on the cooking unit 3, and the discharge port of the cooking unit 3 is located on the mesh-belt drying machine 5, and the mesh-belt spreading The discharge port of the drying machine 5 is provided with a third chain-plate conveyor 7 , and the discharge port of the third chain-plate conveyor 7 is located on the belt dryer 6 .

[0052] refer to figure 2 The soaking unit 2 includes a main chain conveyor 21, two pairs of branch chain conveyors 23 connected to the main chain conveyor 21, a plurality of flashboards 22 arranged on...

Embodiment 2

[0063] refer to Figure 4 , is an automatic linkage line for the pretreatment production of toxic medicinal materials disclosed in the present invention. The difference from Embodiment 1 is that the cooking unit 3 includes a translational diversion conveyor 41, a main ingredient cooking tank 42 and auxiliary ingredients arranged side by side. The medicine boiling tank 43, the translational conveyor 44, and the translational diversion conveyor 41 are used to transport the materials on the main chain plate conveyor 25 to the main material cooking tank 42 and the auxiliary material cooking tank 43, and the main material cooking tank 42 The outlet of the discharge port and the auxiliary material boiling medicine tank 43 are positioned on the translation conveyor 44, and the discharge outlet of the translation conveyor 44 is positioned on the mesh belt type airing machine 5. Wherein, the auxiliary material cooking tank 43 is provided with a liquid suction pump 45 for extracting the...

Embodiment 3

[0067] A processing method of an automatic linkage line for the pretreatment production of toxic medicinal materials, comprising the following steps:

[0068] Step 1, feeding, the main material is transported to the first chain plate conveyor 11, and the main material is transported to each soaking tank 24 through the belt scale, the main chain conveyor 21 and the branch pipe chain conveyor 23 in sequence, and each The main ingredient weight in soak tank 24 is similar;

[0069] Step 2, for medicinal materials that need to be soaked and detoxified with auxiliary materials, the solid auxiliary materials are first conveyed to each soaking tank 24 in equal amounts through the powder material feeding pipe, the main chain conveyor 21 and the branch chain conveyor 23, and then the other The liquid auxiliary materials are delivered to each soaking tank 24 in equal amounts through the metering pump 14 and the liquid medicine feeding pipeline 15 in sequence, and finally the main materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com