A road rock slope construction method

A rocky slope and construction method technology, applied in excavation, infrastructure engineering, construction, etc., can solve the problems of poor appearance, poor overall flatness, and high maintenance costs, so as to improve construction quality and efficiency, reduce Investment, the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

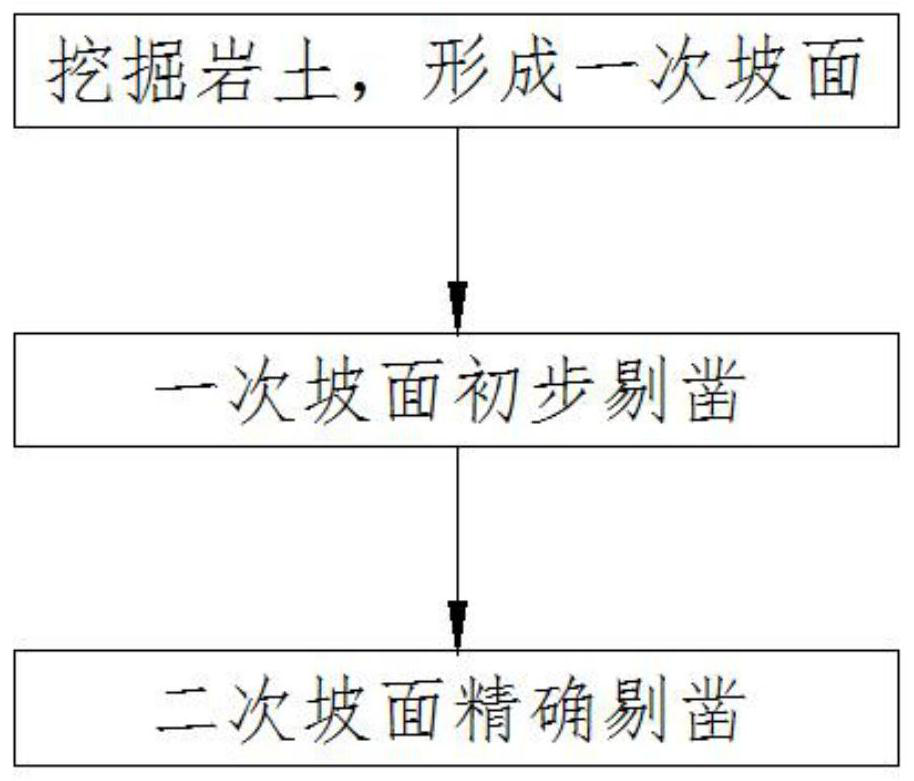

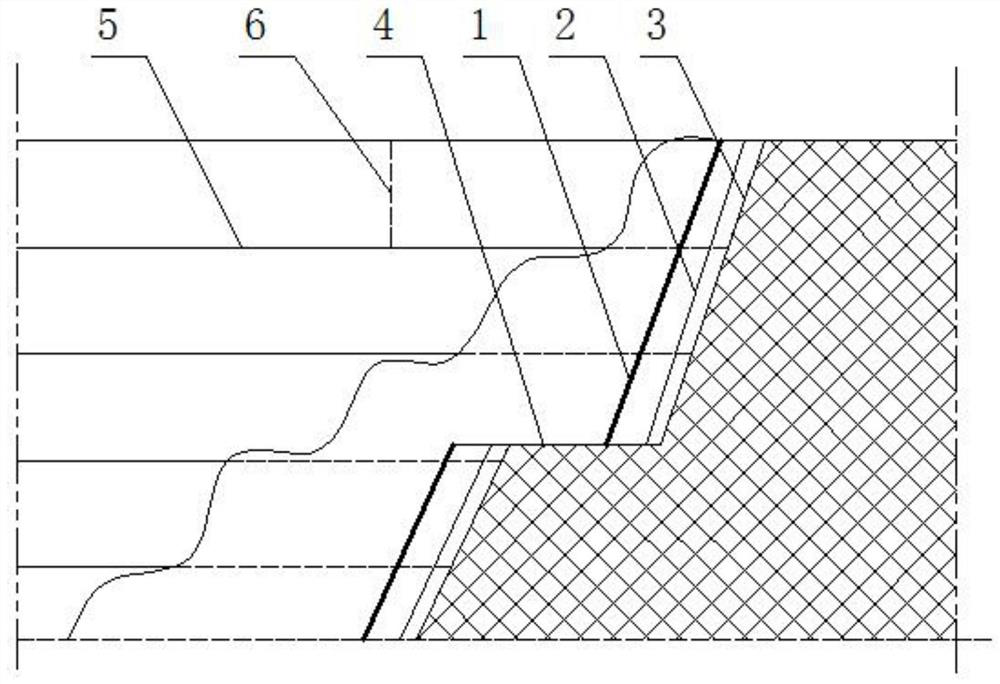

[0023] Such as figure 1 , figure 2 As shown, the invention provides a kind of road rock slope construction method, comprises the following steps:

[0024] Step 1: Use an excavator to excavate the rock and soil, and reserve an appropriate amount of cutting allowance to obtain a slope 1 on both sides of the road; Layer by layer excavation, when excavating each layer of rock and soil, it is excavated segment by segment in the order from the inside of the road to the outside of the road. Layer-by-layer progressive excavation refers to the use of excavators to excavate multiple times, and each layer of rock and soil is excavated. After each layer of rock and soil is excavated, the thickness of the excavated rock and soil is retested to make each layer of rock and soil The thickness is less than 2000mm. Sectional progressive excavat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com