Rapid switching type high-precision positioning vacuum sucker assembly

A vacuum suction cup and fast switching technology, which is applied in the mechanical field, can solve the problems of affecting production capacity, long working hours, and large angle deviation, and achieve the effects of short working hours, high-precision positioning, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

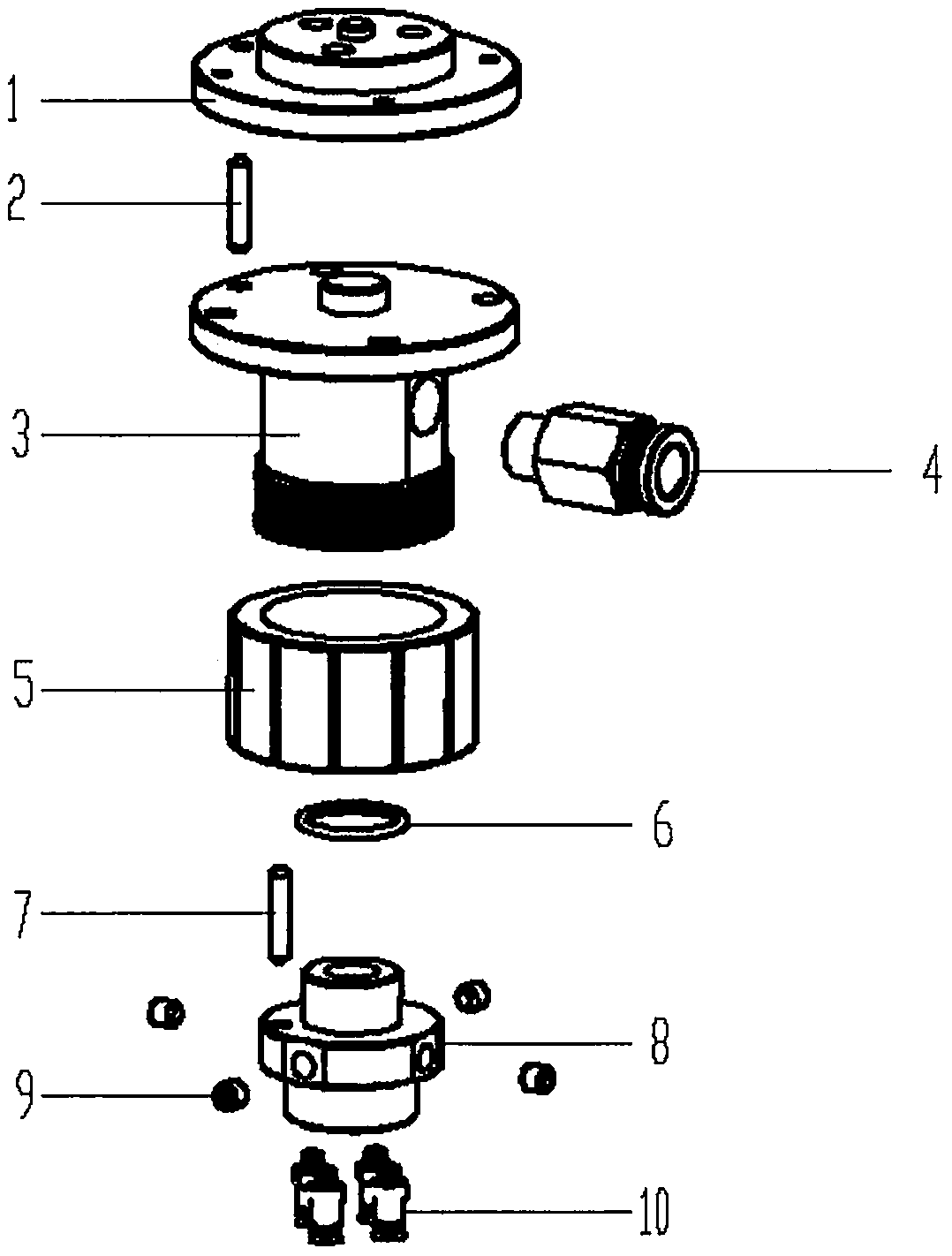

[0026] In order to make the above-mentioned technical solutions of the present invention more obvious and understandable, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

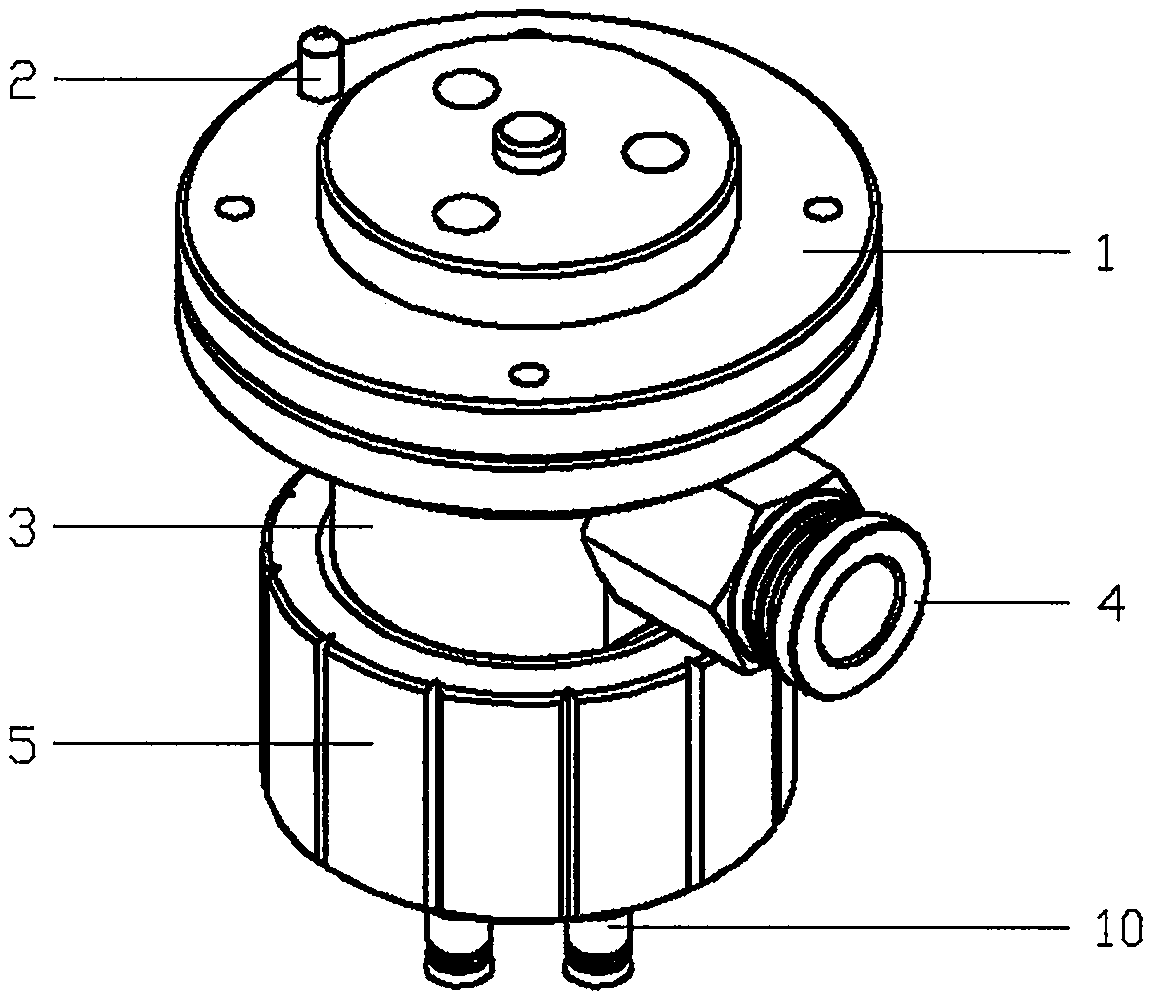

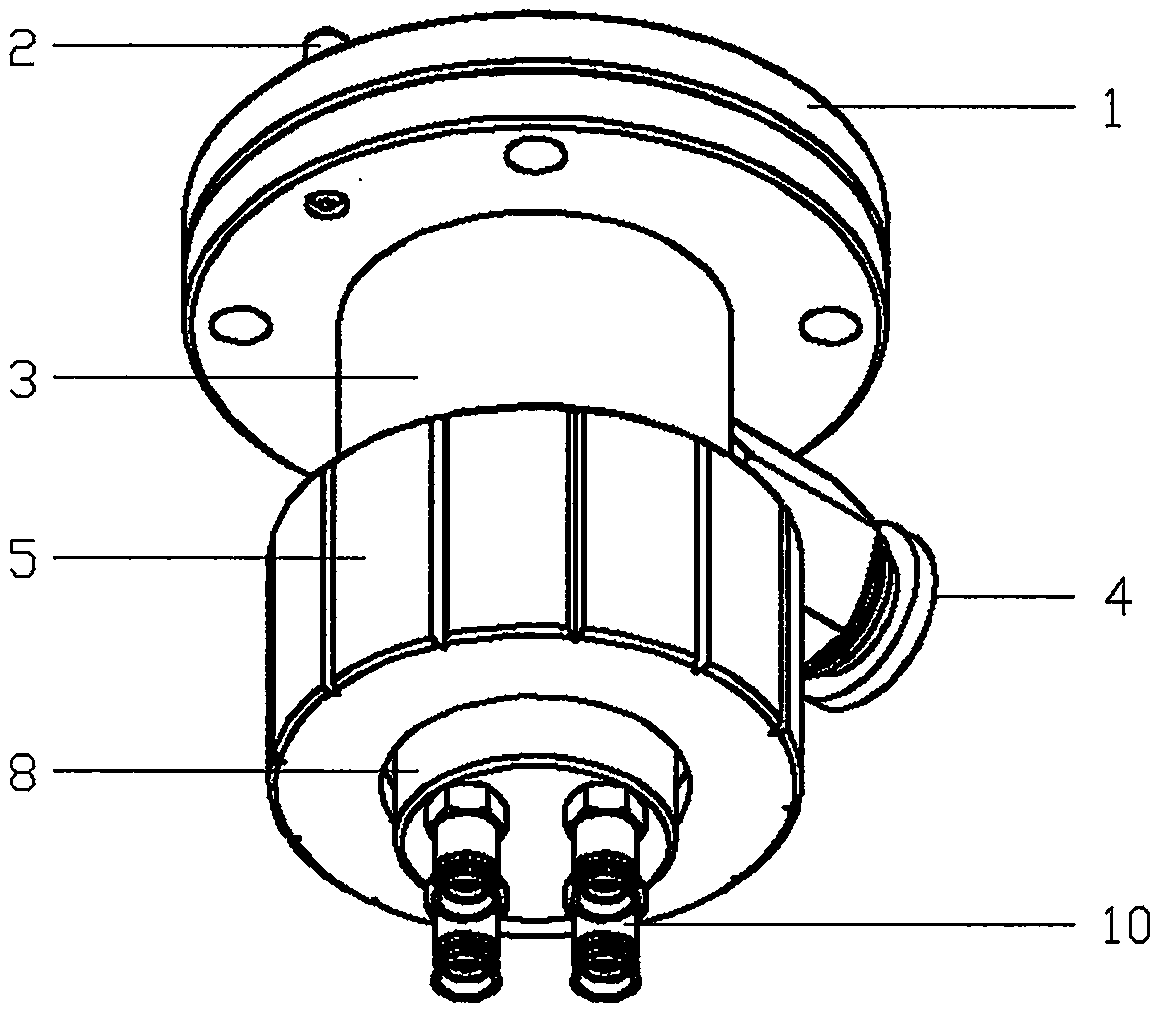

[0027] Referring to Figure 1(a), Figure 1(b) and figure 2 , The fast-switching high-precision positioning vacuum suction cup assembly provided by the present invention includes: a connecting plate 1, a gas pipe joint fixing seat 3, a gas pipe joint 4, a lock nut 5, a suction cup fixing seat 8, a plug 9 and a suction cup 10.

[0028] 1. Connecting plate, gas pipe joint fixing seat

[0029] The connecting plate 1 and the trachea joint fixing seat 3 are positioned and connected together by the locating pin 2, and the locating pin 2 is used to ensure that the relative position between the connecting plate 1 and the trachea joint fixing seat 3 is fixed.

[0030] The structure of the connecting plate 1 is shown in Fig. 3(a) and Fig. 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com